Positioning laser certificate anti-fake thin film for individually printing and preparation method thereof

A technology of laser and thin film, applied in the field of anti-counterfeiting film for positioning laser documents and its preparation, can solve the problems of unfavorable large-area laminated cards, easy to be replaced, card body warping, etc., to achieve enhanced security and social stability, Simplify the certification equipment and process, unique effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

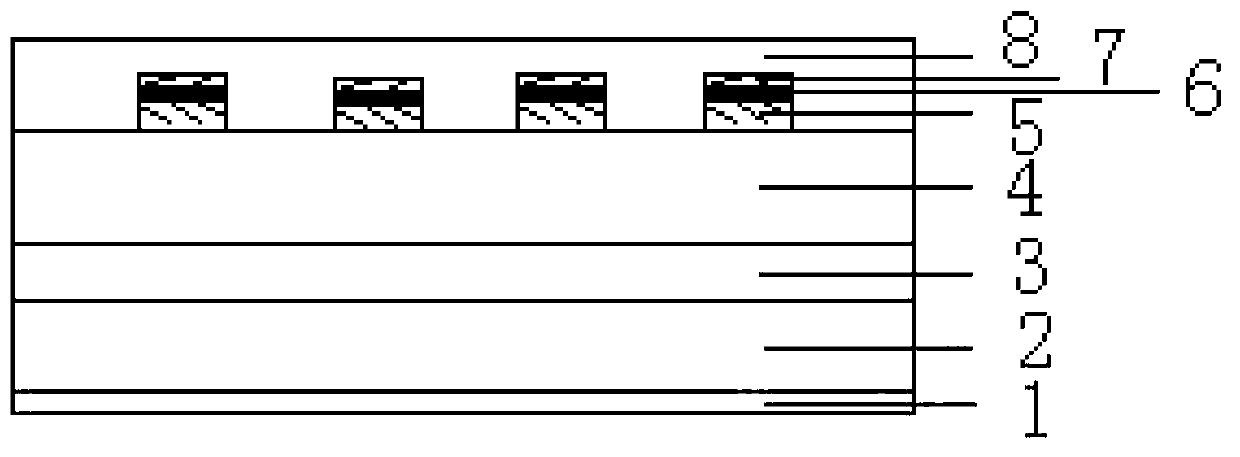

[0024] The invention relates to a certificate anti-counterfeiting film and its preparation method which is applied in the field of anti-counterfeiting and has the functions of personalized printing and positioning laser anti-counterfeiting. An anti-counterfeit film with special printing on it by a specific process. The structure of the anti-counterfeit film is anti-static layer 1, substrate 2, composite adhesive layer 3, substrate 4, laser information layer 5, reflective medium layer 6, anti-counterfeit graphics Layer 7, adhesive layer 8.

[0025] Among them, the antistatic layer is a coating made of a variety of polymers containing conjugated π electron structures or water-soluble polymer materials containing sulfonic acid groups, carboxyl groups, and hydroxyl groups, or a coating containing conductive powders containing rare earth oxides. Resin coating, which is coated on the outermost layer of the film layer, to ensure that the material can be printed in large quantities wi...

Embodiment 1

[0035] The PVC film with a thickness of 60 μm is used as the substrate, and the light-cured coating is partially rolled on it. The graphic surface of the metal nickel plate engraved with laser information such as orthogonal optical change and 3D dynamic graphics and text is completely bonded to the light-curing coating under a pressure of 3000N / m2, and an ultraviolet lamp with a light intensity of 120w / cm is used for light treatment. After curing, the dry film thickness of the coating is 2.0-2.5 μm. Remove the metal nickel plate to obtain a PVC film with localized positioning and printed laser graphics. Physical deposition of a layer of SiO by thermal evaporation on photocurable coatings 2 Coating, the thickness is about 60nm. Use gravure printing to print anti-counterfeit graphics on the coating, chemically corrode after drying, and obtain laser graphics with enhanced local reflection. Then apply a layer of water-based polyurethane hot melt adhesive by roller coating, dry ...

Embodiment 2

[0037] Under the same conditions as in Example 1, change the laser information, change the PET film base material into 80g coated paper, use LED to print the head portrait and personal information on the PVC adhesive layer, and use the card core with the chip After lamination, the portrait information with high resolution and good reproducibility can be obtained, which is both beautiful and anti-counterfeiting. It is suitable for making student ID cards, high-end club membership cards and other ID documents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com