Emergency repair method for concrete box girders

A technology of concrete box girders and concrete bottom slabs, applied in bridge maintenance, bridges, bridge reinforcement, etc., can solve the problems of low vehicle speed, unsuitable for emergency repairs, large deformation of beams, etc. The effect of line operation and reduction of emergency repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Example 1 A double-line integrally prestressed concrete high-speed railway box girder with a span of 32 meters was damaged due to the impact of vehicle loads during operation. For this reason, the emergency repair method of concrete box girder is used for repair. The repair method is:

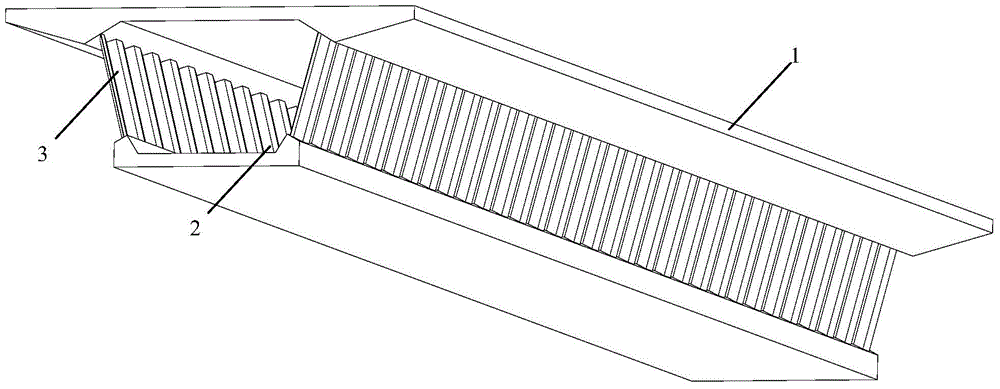

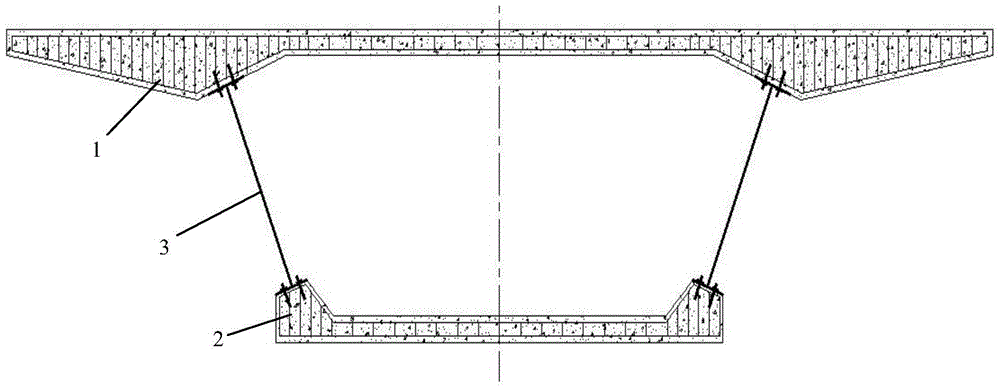

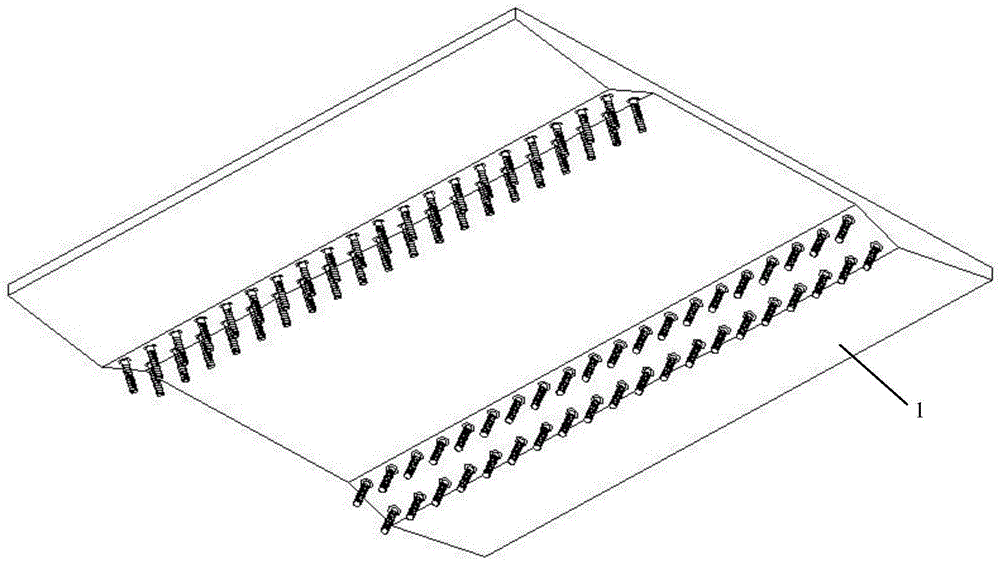

[0034] Step 1: Prefabricate the concrete roof 1, concrete bottom 2, and corrugated steel web 3 according to the size and specification of the 32-meter double-line integral prestressed concrete high-speed railway box girder and store them in the beam storage yard;

[0035] Step 2: remove the damaged concrete box girder, and set up supports 5 between the bridge piers 4 on site;

[0036] Step 3: Go to the beam storage yard and transport the prefabricated concrete roof 1, concrete floor 2, and corrugated steel web 3 to the emergency repair site;

[0037] Step 4: hoisting the concrete bottom plate 2 to the erected support 5, then hoisting the corrugated steel web 3 and performing bolt assem...

example 2

[0039] Example 2 A double-track integrally prestressed concrete heavy-duty railway box girder with a span of 24 meters was damaged by landslides during operation. For this reason, the emergency repair method of concrete box girder is used for repair. The repair method is:

[0040] Step 1: Prefabricate the concrete top plate 1, concrete bottom plate 2, and corrugated steel web 3 according to the size and specification of the 24-meter double-line integral prestressed concrete heavy-duty railway box girder and store them in the beam storage yard;

[0041] Step 2: remove the damaged concrete box girder, and set up supports 5 between the bridge piers 4 on site;

[0042] Step 3: Go to the beam storage yard and transport the prefabricated concrete roof 1, concrete floor 2, and corrugated steel web 3 to the emergency repair site;

[0043] Step 4: hoisting the concrete bottom plate 2 to the erected support 5, then hoisting the corrugated steel web 3 and performing bolt assembly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com