BOPP (Biaxially-oriented Polypropylene) thin film for soft-pack stiff-casement cigarette with wrinkle resistance and wear resistance and preparation method of BOPP thin film

A soft-pack hard-film technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as unsuitable dark cigarette packaging, user complaints or returns, and fuzzy cigarette label patterns, etc., to achieve smooth packaging Wrinkle, high grade, good anti-sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

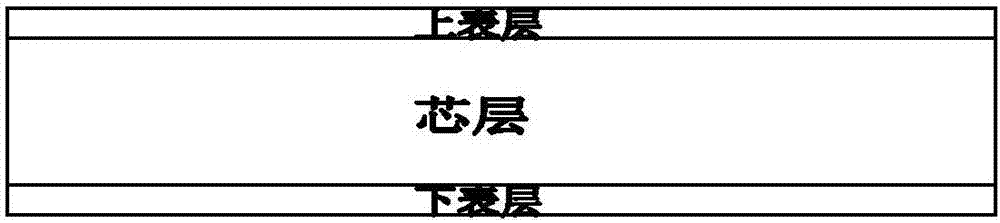

[0030] refer to figure 1 , the BOPP film for soft-packed and hard-packed cigarettes with anti-wrinkle and wear resistance involved in this embodiment is made by direct co-extrusion and compounding of the three-layer structure of the upper surface layer, the core layer and the lower surface layer; the main component of the upper surface layer is polypropylene copolymer , the main component of the core layer is polypropylene homopolymer, and the main component of the lower surface layer is polypropylene copolymer; by 100 parts by weight, the material components of each physical layer are as follows:

[0031] The material components of the upper surface layer are: 91 parts by weight of copolymer polypropylene, 6 parts by weight of slip agent masterbatch, and 3 parts by weight of anti-tack agent masterbatch; the carrier of slip agent masterbatch and anti-tack agent masterbatch is copolymer poly The active ingredient of propylene and slip agent masterbatch is high-viscosity silicon...

specific Embodiment 2

[0052] The feature of this specific embodiment 2 is that the material components of each physical layer are as follows:

[0053] The material components of the upper surface layer are: 90 parts by weight of copolymer polypropylene, 8 parts by weight of slip agent masterbatch, 2 parts by weight of anti-tack agent masterbatch, and the carrier of slip agent masterbatch and anti-tack agent masterbatch is copolymer polypropylene , the active ingredient of slip agent masterbatch is silicone resin, the concentration is 10%; the active ingredient of anti-sticking agent masterbatch is silicon dioxide particles, the concentration is 5%;

[0054] The material components of the core layer are: 79 parts by weight of homopolymer polypropylene, 18 parts by weight of stiffener masterbatch, and 3 parts by weight of static agent masterbatch; the carrier of stiffener masterbatch and antistatic agent masterbatch is homopolymer Polypropylene, the active ingredient of stiffening agent masterbatch i...

specific Embodiment 3

[0058] The characteristics of the specific embodiment 3 of the present invention are: based on 100 parts by weight, the material components of the upper surface layer are: 79 parts by weight of copolymer polypropylene, 16 parts by weight of slip agent masterbatch, and 5 parts by weight of anti-sticking agent masterbatch; The material components of the core layer are: 79 parts by weight of homopolymer polypropylene, 19 parts by weight of stiffening agent masterbatch, and 2 parts by weight of static agent masterbatch; the material components of the lower surface layer are: 100 parts by weight of copolymer polypropylene.

[0059] All the other are with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stretch temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com