Production equipment and process of copper-clad aluminum bimetal composite wire rod

A composite wire and bimetal technology, applied in the field of metal material processing, can solve the problems of difficult processing of bimetal composite wire, uneven shrinkage, affecting the quality of copper-clad aluminum bimetal composite wire, etc., and achieves good internal organization and dimensional accuracy. Precise, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

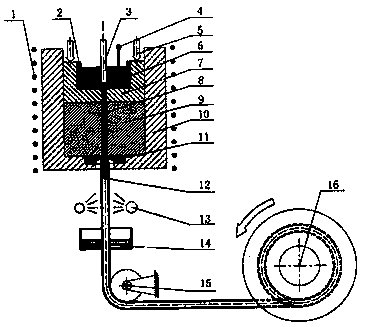

[0014] figure 1 It is a specific embodiment of the device of the present invention. The equipment consists of a pressure mechanism 5, an extrusion cylinder 10, an extrusion rod 7, an extrusion die 11, a cladding layer metal 9, a hollow perforating needle 8, a heating element 1 and a thermometer 4 to form an extrusion system for an outer metal copper tube. Temperature control crucible 2, core metal pouring stopper rod 3, hollow piercing needle 8, heating element 1, thermometer 4, cooling device 13 and water tank 14 constitute the pouring and solidification system of core metal aluminum liquid; by tension mechanism 15 and The winder 16 constitutes a collection system for the product. The heating element 1 adopts resistance heating or induction heating. The temperature control crucible 2 and the pouring stopper 3 are made of refractory material or cermet. The extrusion barrel 10, the extrusion rod 7, the extrusion die 11 and the hollow perforating needle 8 are made of hot work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com