Wrapping cover method suitable for isothermal forging of Ti-Al-series intermetallic compound

An intermetallic compound and isothermal forging technology, which is applied in the field of warm forging sheathing, can solve the problems of narrow deformation temperature range, easy cracking, easy drum shape of the material, and difficult deformation of the upper and lower surfaces, so as to meet the requirements of simple forging equipment and reduce the temperature. The effect of loss and narrow heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A sheathing method suitable for isothermal forging of Ti-Al intermetallic compounds. The Ti-Al intermetallic compound in this embodiment is Ti 2 For AlNb-based alloys, the size of the sheath depends on the size of the billet 3 . The sheath of the invention has heat preservation effect, good deformation coordination, is easy to weld, simple and easy to operate, reduces vacuuming process, and improves production efficiency. The structure of the bag is simple and practical, low cost, easy to operate, and can be used for Ti 2 AlNb-based alloys are produced by isothermal forging, and are also suitable for other difficult-to-deform alloys and high-temperature alloys. The specific operation steps are as follows:

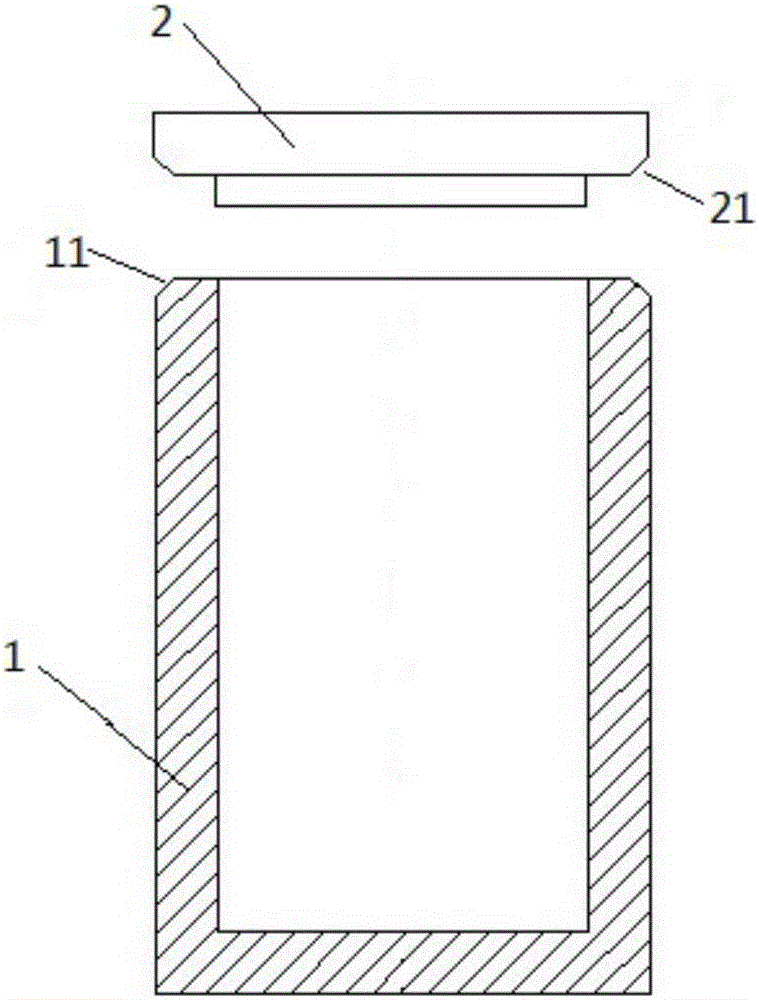

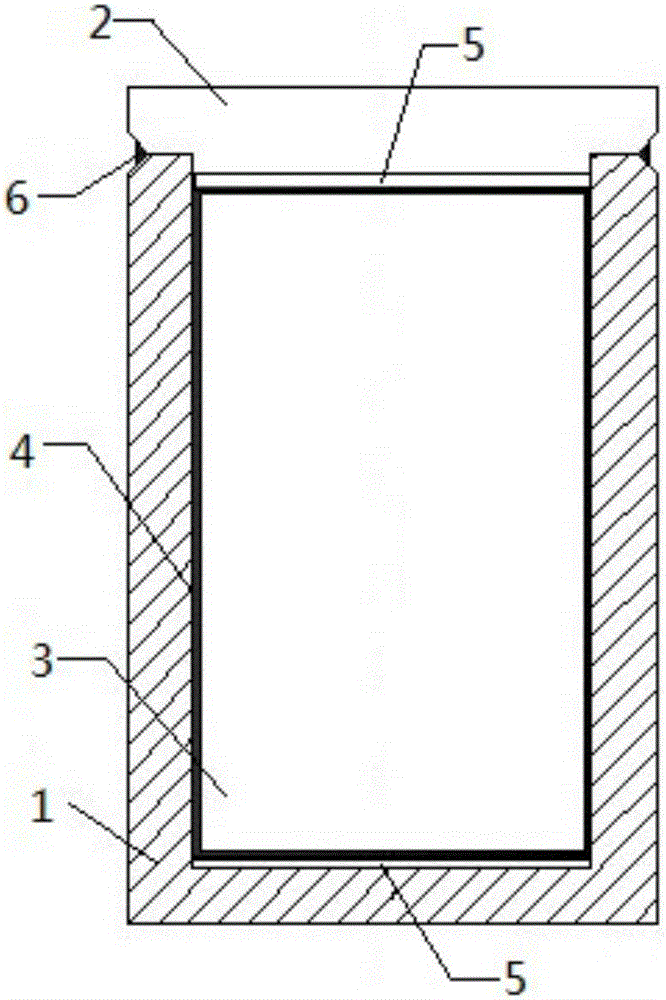

[0042] 1. Preparation of sheathing: The size of the blank 3 is Φ60×100mm, and the wall thickness of the sheathing is selected as 10mm in consideration of the size of the blank 3, heat preservation and deformation coordination. The sheath material is low carbon st...

Embodiment 2

[0051] A sheathing method suitable for isothermal forging of Ti-Al intermetallic compounds. The Ti-Al intermetallic compound in this embodiment is Ti 2 For AlNb-based alloys, the size of the sheath depends on the size of the billet 3 . The sheath of the invention has heat preservation effect, good deformation coordination, is easy to weld, simple and easy to operate, reduces vacuuming process, and improves production efficiency. The structure of the bag is simple and practical, low cost, easy to operate, and can be used for Ti 2 AlNb-based alloys are produced by isothermal forging, and are also suitable for other difficult-to-deform alloys and high-temperature alloys. The specific operation steps are as follows:

[0052] 1. Preparation of sheath: The sheath can be made of stainless steel, pure titanium or titanium alloy. The size of the blank 3 in this embodiment is Φ60×109mm. Considering the size of the blank 3, insulation and deformation coordination, the wall thickness o...

Embodiment 3

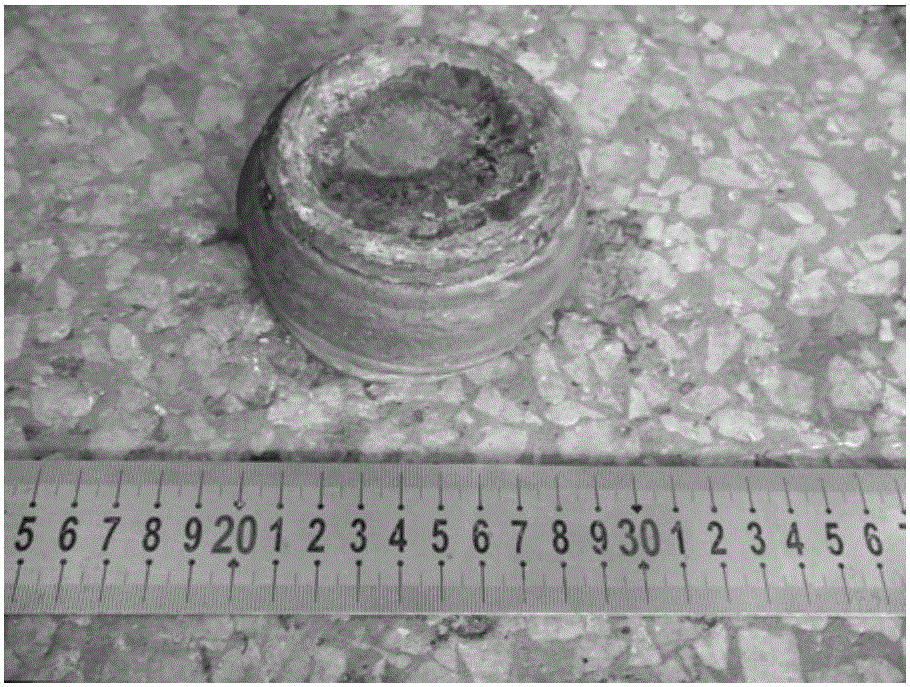

[0061] A sheathing method suitable for isothermal forging of Ti-Al intermetallic compounds. This example is basically the same as Example 1, the difference is that the Ti-Al intermetallic compound in this embodiment is a TiAl-based alloy, and the isothermal forging process parameters of this example are: billet temperature 1200°C / 2.5h, The mold temperature is 950°C, and the strain rate of isothermal forging is 1×10 -2 the s -1 , The amount of deformation is 60%. After isothermal forging, the blank with sheath is annealed at 1100℃ / 10h. The photo of the sample after isothermal forging to remove the sheath is as follows image 3 with Figure 4 shown. Depend on image 3 with Figure 4 Yes, after one-step sheathed isothermal forging, the surface quality of the TiAl-based alloy sample is better, and no microcracks occur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com