Flange die-forging technology

A die forging and process technology, which is applied in the field of flange die forging technology, can solve problems such as pits and double drums on the end face of the flange, and achieve the effects of reducing work hardening, ensuring uniformity, and eliminating cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

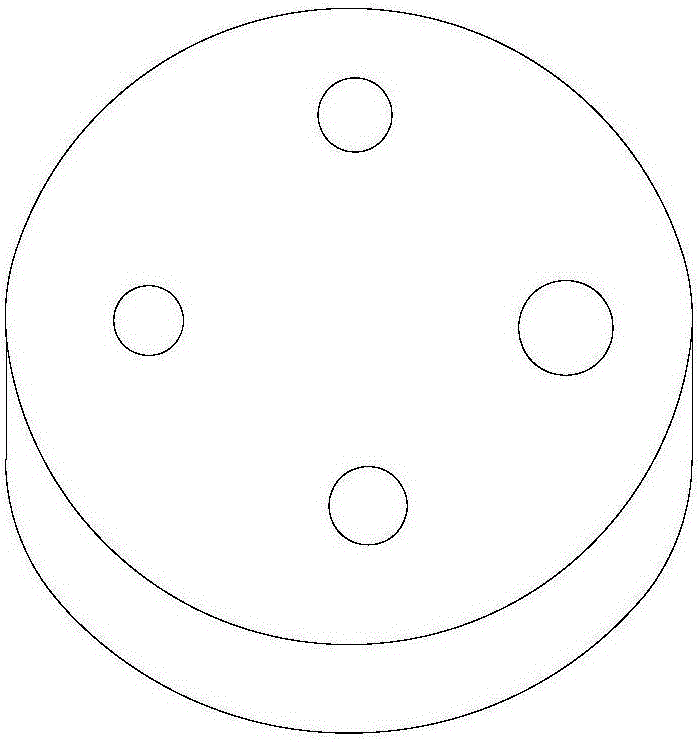

[0017] Describe in detail below in conjunction with specific embodiment according to accompanying drawing:

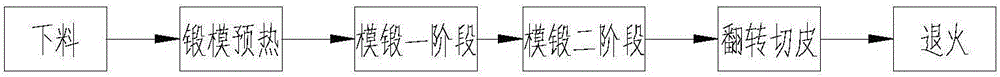

[0018] A flange die forging process, comprising the following steps:

[0019] S1: blanking;

[0020] S2: Preheating the forging die, the preheating temperature is 200°C-250°C;

[0021] S3: the first stage of die forging, the initial forging temperature of the die forging is 1100°C-1200°C, and the cooling time between the first stage of die forging is 18s-20s;

[0022] S3: the second stage of die forging, the temperature of the forging is 700°C-800°C, and the cooling time between the two stages of die forging is 9s-11s;

[0023] S4: Flip and cut the skin;

[0024] S5: annealing, the annealing temperature is 1150°C-1250°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com