Device for repairing aircraft thin-walled beam through laser deposition and repairing method thereof

A technology of laser deposition and repair method, applied in metal material coating process, coating and other directions, can solve problems such as increasing production cost, reducing repair quality, edge sagging of aircraft thin-walled beams, etc., achieving low-cost repair, improving comprehensive performance, Repair the effect of the slump phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

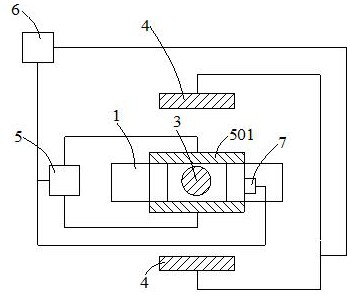

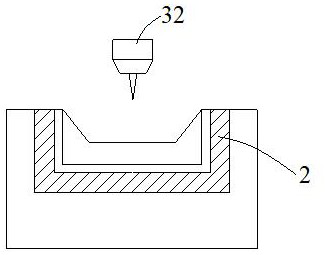

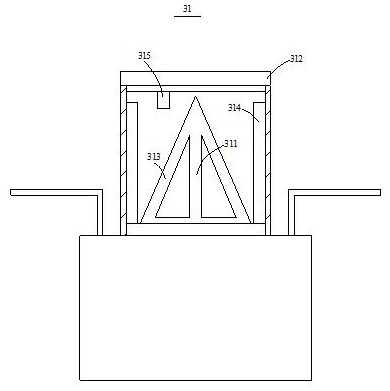

[0052] like Figure 1~4 As shown, the present invention provides a device for repairing thin-walled beams of aircraft by laser deposition, comprising: a heating plate 2 for carrying thin-walled beams 1 of aircraft to be repaired; a laser deposition platform 3 for repairing thin-walled beams of aircraft to be repaired; The magnetic field auxiliary platform 4 is used to provide a magnetic field of variable direction and intensity, and the alternating magnetic field auxiliary platform 4 is fixed on the laser deposition platform 3; the liquid nitrogen forced cooling device 5 is used to cool the repaired aircraft thin-walled beam 1 wherein the aircraft thin-walled beam 1 to be repaired is carried on the heating plate 2 for heating, and is repaired by the laser deposition platform 3 under the magnetic field environment provided by the alternating magnetic field auxiliary platform 4, and then forced by the liquid nitrogen The repaired aircraft thin-walled beam 1 is cooled under the a...

Embodiment 2

[0066] Embodiment 2 can be performed on the basis of Embodiment 1.

[0067] like Figure 1~4 As shown, Embodiment 2 provides a repair method for repairing thin-walled beams 1 of an aircraft by laser deposition. The repair method includes, during the repair process, providing an alternating magnetic field. The strength of the alternating magnetic field can be adjusted, and the direction can also be changed. , according to different processing parameters to achieve the adjustment of the strength and direction. Wherein, the processing parameters include processing position, processing area and processing thickness, and the strength of the alternating magnetic field is adjusted according to different processing thicknesses, that is, the deeper the thickness, the greater the strength of the alternating magnetic field. Wherein, the position of the alternating magnetic field only needs to ensure that it can act on the molten pool of laser cladding.

[0068] As for the processing po...

Embodiment 3

[0074] like Figure 1~4 As shown, the third embodiment is a supplement to the whole process of the second embodiment.

[0075] S1, perform non-destructive testing on the area to be repaired of the thin-walled beam 1 of the aircraft, cut and trim the damaged part of the thin-walled beam to be repaired in a regular manner, polish, clean and dry, and clamp it on the laser deposition platform 3;

[0076] S2, according to the size and shape of the prefabricated repair, use the computer 6 to build a three-dimensional model and plan the path to feed back to the laser deposition platform 3;

[0077] S3, heating the aircraft thin-walled beam 1 to be repaired to 300°C~600°C, and feeding back the temperature to the computer 6;

[0078] S4, adjust the alternating magnetic field, input the preset alternating magnetic field program in the computer 6, input the processing parameters to the laser deposition platform 3, and perform the first layer of laser deposition repair processing. At thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com