Metal matrix composite material composite additive manufacturing device and manufacturing method

A composite material and additive manufacturing technology, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problems of coarse microscopic crystal structure, poor mechanical properties of materials, lack of fusion, etc., to improve internal quality and mechanical properties or the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

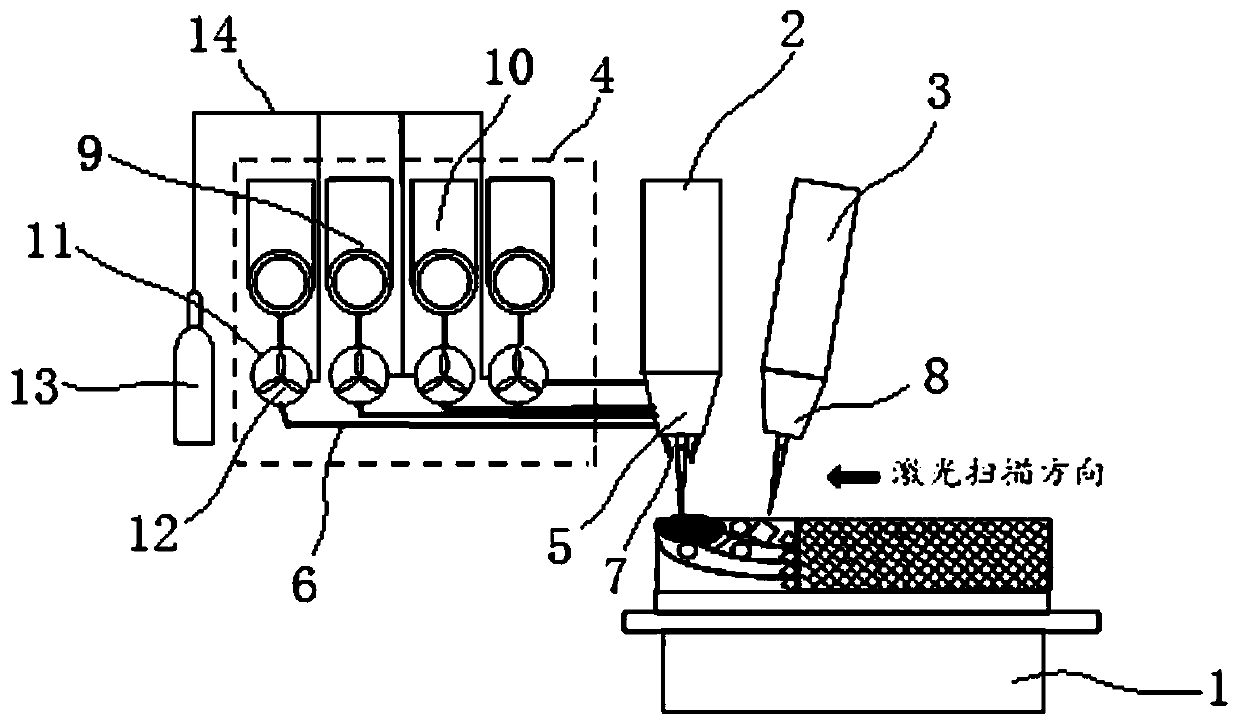

[0028] Such as figure 1 As shown, a metal matrix composite composite additive manufacturing device includes a workbench 1, a cladding laser beam generating mechanism 2 and a pulsed laser beam generating mechanism 3 that are arranged above the workbench 1 and can move along the direction of the workbench. One side of table 1 is provided with powder feeding mechanism 4 for conveying metal powder and non-metal powder; The powder feeding head 7 and the pulse laser beam generating mechanism 3 are provided with a pulse laser head 8 . In this embodiment, the powder feeding mechanism 4 blows the metal powder and non-metal powder through the coaxial powder feeding head 7, and the cladding laser beam generating mechanism 2 generates a cladding laser beam, and cladding the metal powder and non-metal powder with laser The radiation and melting of the beam form a molten pool until it solidifies into a cladding layer; the pulse laser beam generating mechanism 3 emits a pulse laser beam, an...

Embodiment 2

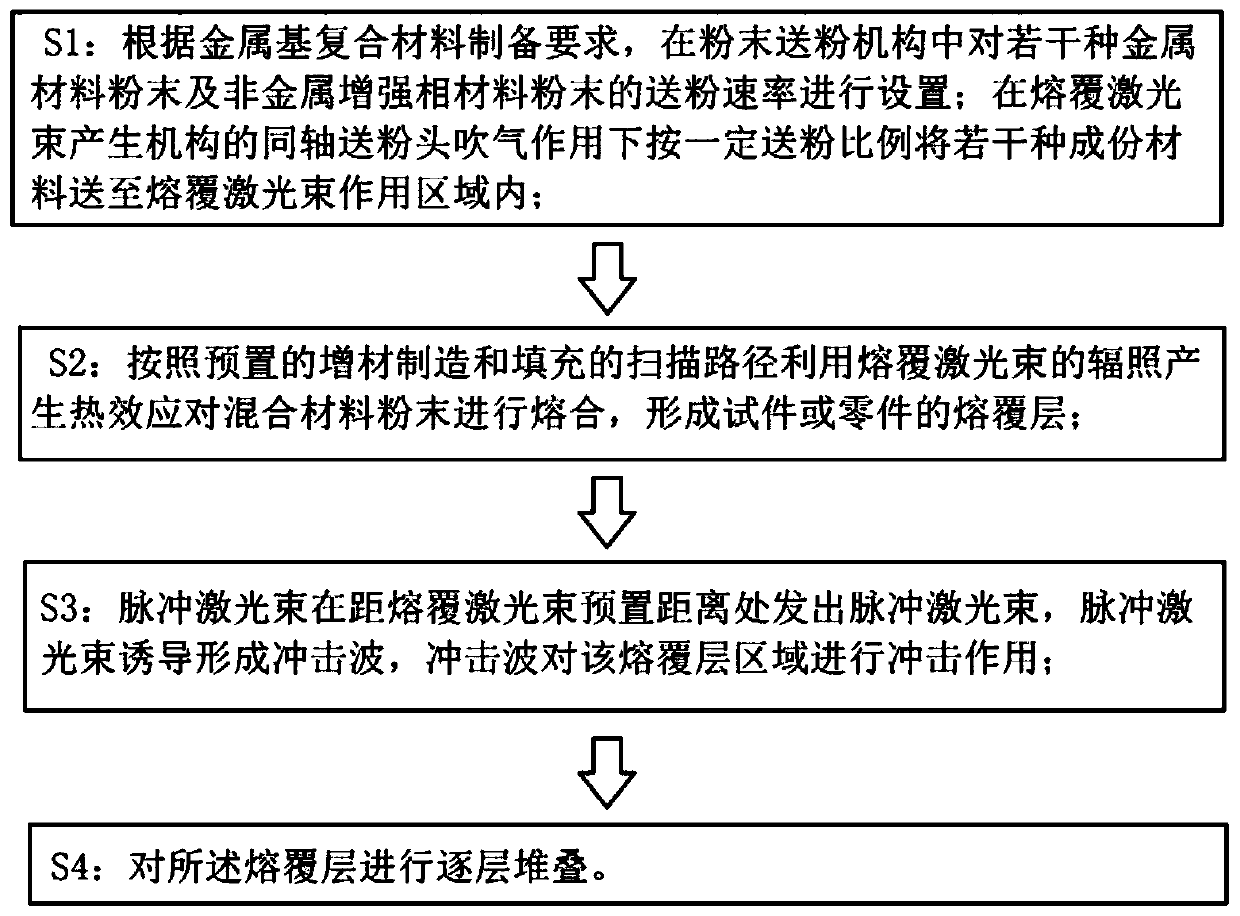

[0033] Such as figure 2 Shown, a kind of metal matrix composite composite additive manufacturing method comprises the following steps:

[0034] S1: According to the preparation requirements of metal matrix composite materials, set the powder feeding rate or powder feeding ratio of several metal material powders and non-metallic reinforcement phase material powders in the powder feeding mechanism 4; Under the blowing action of the coaxial powder feeding head 7, several kinds of component materials are sent to the cladding laser beam action area according to a certain powder feeding ratio;

[0035] S2: According to the preset scanning path of additive manufacturing and filling, the thermal effect generated by the irradiation of the cladding laser beam is used to fuse the mixed material powder to form the cladding layer of the test piece or part;

[0036] S3: While the cladding laser beam is working, the computer adjusts and sets the distance between the cladding laser beam and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com