Tool and method for forging crank throw on double-action hydraulic press

A technology of process equipment and hydraulic presses, applied in the driving device, mechanical equipment, manufacturing tools and other directions of forging presses, can solve the problems of ring forging forgings, which are difficult to form, not suitable for small batch production, and not very practical. Simple, eliminate internal defects, improve molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

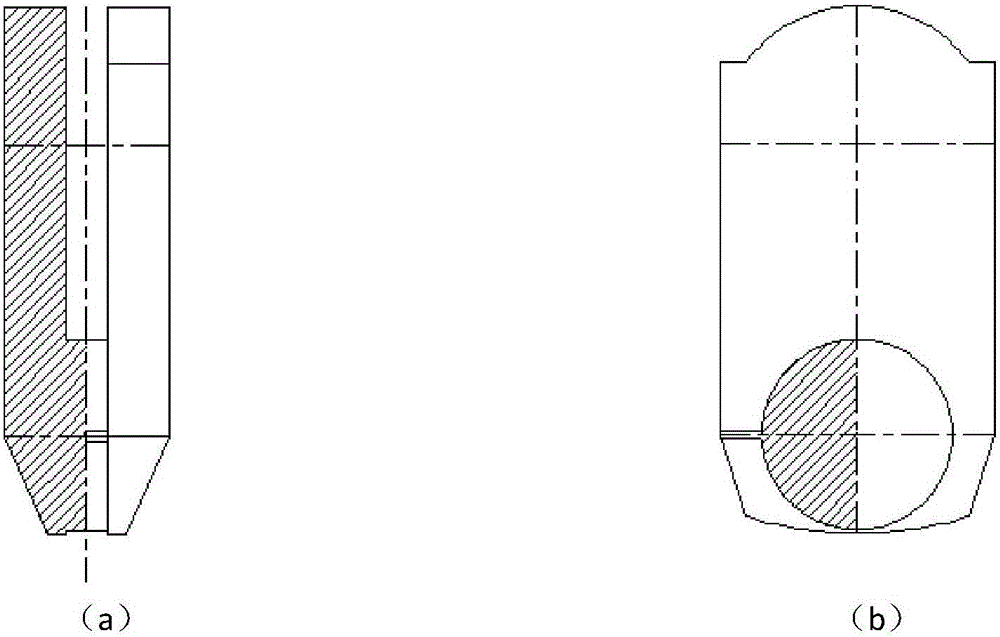

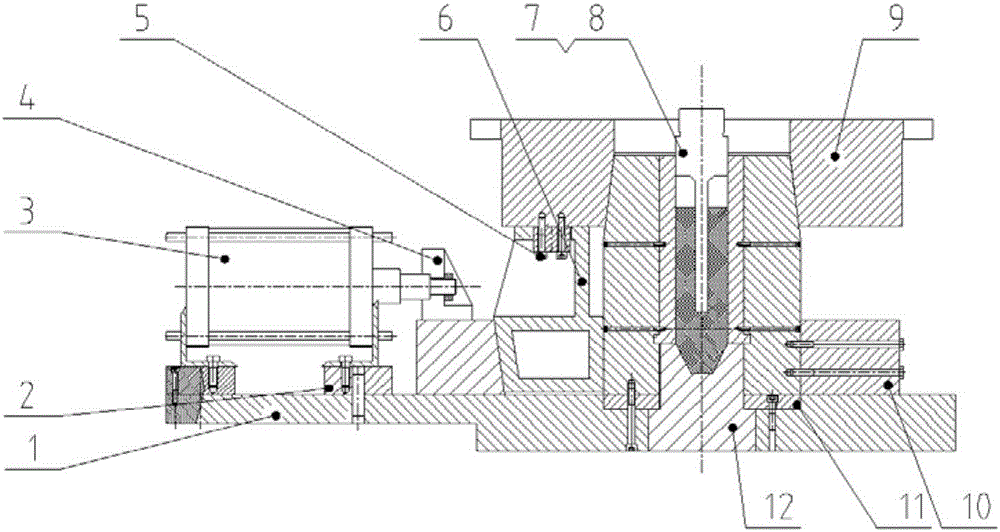

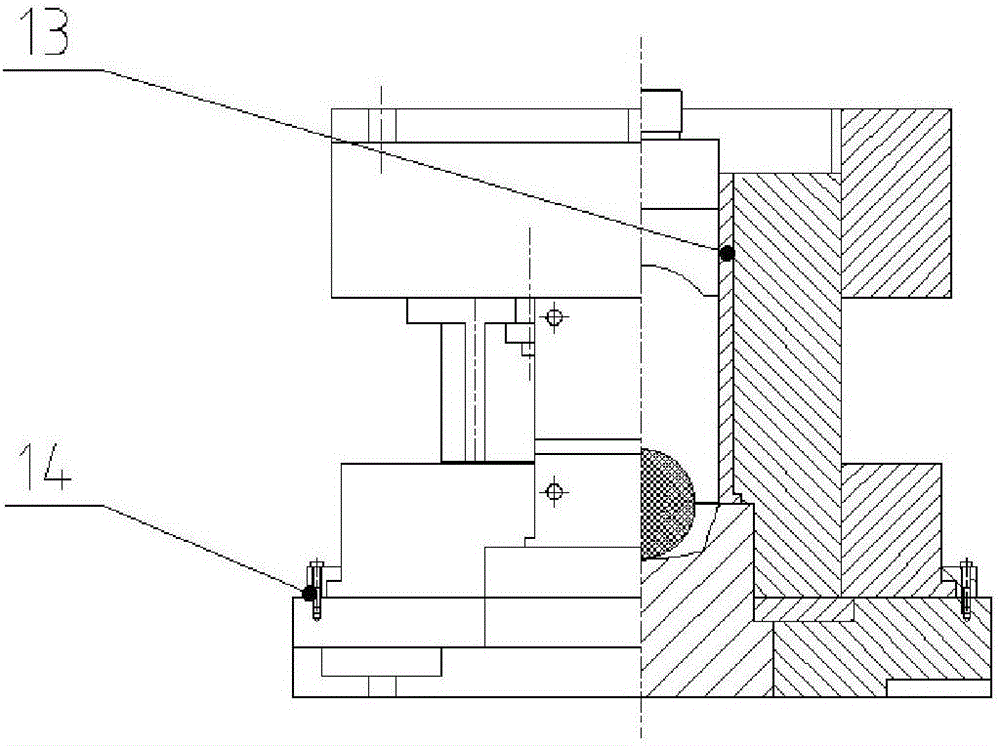

[0027] In the embodiment of the present invention, according to figure 1 For the crank throws shown in a and b, the technical equipment for forging the crank throws on the double-action hydraulic press is designed. The specific structure is as follows Figure 2-12 shown.

[0028] The process equipment of the present invention includes the upper closing template 9 fixed on the outer slider of the double-acting hydraulic press, which is connected with the clamping support frame 6 through the clamping frame fixing block 5, and the upper closing template 9 is driven by the outer slider of the double-acting hydraulic press to It is placed on the top of the closed mold cavity, and the upper closing template 9 is provided with a trapezoidal area with an inclination angle of α=7°, which closely fits with the inclined surface with the same inclination angle α on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com