Annealing method of cerium-doped yttrium aluminium garnet wafer for white-light LED (Light Emitting Diode)

A technology doped with yttrium aluminum garnet and cerium, which is applied in the field of LED fluorescent materials, can solve problems such as easy aging, poor particle size and dispersion uniformity, and uneven coating, so as to improve transmittance, eliminate oxygen vacancies, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

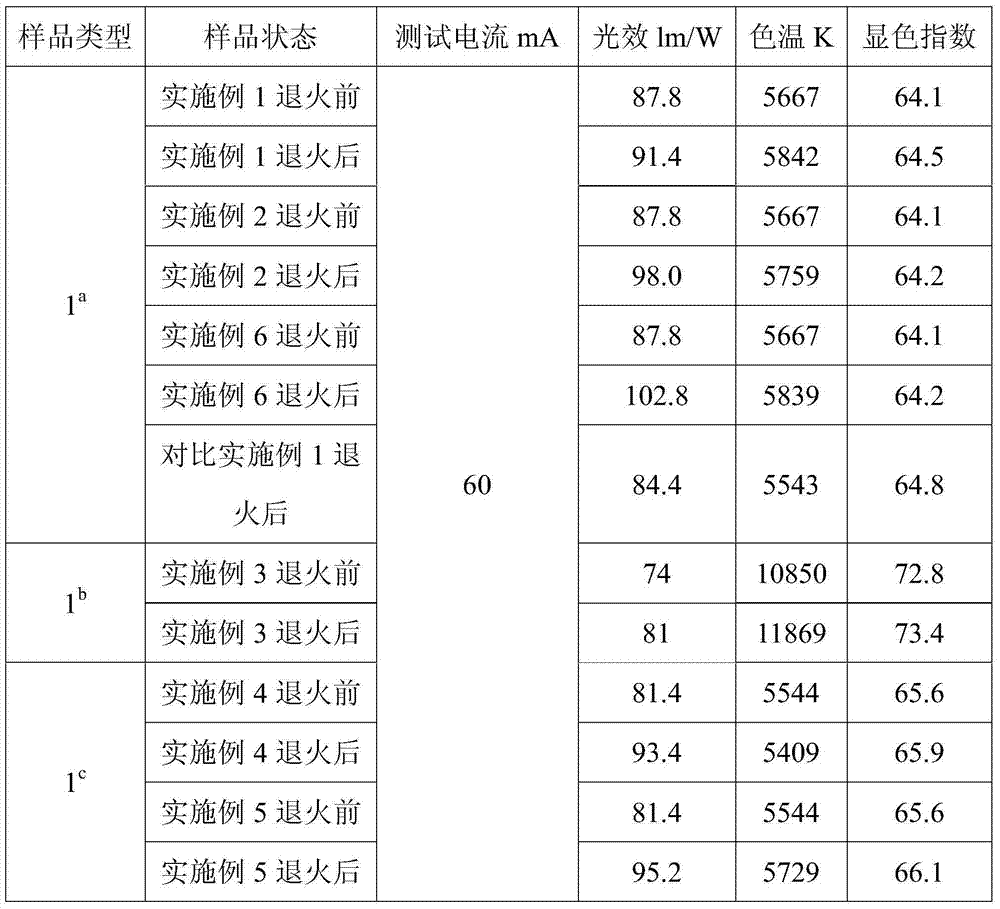

Examples

Embodiment 1

[0027] According to the stoichiometric formula (Y 1-x Ce x ) 3 (Al 1-y Ga y ) 5 o 12 (x=0.04 / 3, y=0) Weigh Y with purity ≥99.99% 2 o 3 、Al 2 o 3 , CeO 2 Raw materials, ground and mixed evenly, briquetted, pre-fired at 1200°C for 24 hours, then transferred to the intermediate frequency induction single crystal furnace together with the seed crystal, and the sealed system was vacuumed to 10 -4 P a , when the furnace temperature reaches 1400°C, nitrogen with a purity greater than 99% is introduced, and the temperature continues to rise to 1900°C in this atmosphere, and the temperature is kept for 2 hours. By adjusting the temperature of the furnace until the raw materials are melted, after inoculation, shouldering, equal diameter, and finishing Waiting for the process to pull and grow Y 2.96 Al 5 o 12 : Ce 0.04 crystals. The crystal growth direction is the direction. After the growth is over, slowly cool down to room temperature at a rate of 25°C / h, and the Y 2....

Embodiment 2

[0029] With the 4mm*4mm*0.5mmY obtained according to the method of embodiment 1 2.96 Al 5 o 12 : Ce 0.04 After the wafer is polished, it is sent into the tubular annealing furnace, and after vacuuming, the O 2 , adjust the pressure in the furnace to 0.05MPa, rise from room temperature at 120°C / h to 300°C and keep it for 3 hours, then raise it at 150°C / h to 900°C and keep it for 3 hours, and finally rise to 1500°C at 100°C / h, 3 After heating up, keep 1500°C for 24 hours, then cool down to 1100°C at a rate of 50°C / h, cool to 900°C at a rate of 100°C / h, and drop to room temperature at a rate of 200°C / h to obtain the annealed Y 2.96 Al 5 o 12 : Ce 0.04 Chip, this chip can be used to package high-performance white light LED.

Embodiment 3

[0031] According to the stoichiometric formula (Y 1-x Ce x ) 3 (Al 1-y Ga y ) 5 o 12 (x=0.03 / 3, y=0) Weigh Y with purity ≥99.99% 2 o 3 、Al 2 o 3 , CeO 2 Raw materials, ground and mixed evenly, briquetted, pre-fired at 1200°C for 12 hours, then transferred to the intermediate frequency induction single crystal furnace together with the seed crystal, and the sealed system was vacuumed to 10 -4 Pa, when the furnace temperature reaches 1400°C, nitrogen with a purity greater than 99% is introduced, and the temperature continues to rise to 1850°C in this atmosphere, and the temperature is kept for 2 hours. By adjusting the temperature of the furnace until the raw materials melt, and then through inoculation, shouldering, equal diameter, Finishing and other processes to lift and grow Y 2.97 Al 5 o 12 : Ce 0.03 crystals. The crystal growth direction is the direction. After the growth is over, slowly cool down to room temperature at a rate of 20°C / h, and the Y 2.97 Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com