Blank making method for 42CrMoA axial forging

A technology for forgings and shafts, which is applied in the blank-making field of 42CrMoA shaft forgings. It can solve problems such as inability to loosen, shrinkage cavity, and welding of central cracks, and achieve the effects of eliminating internal defects, low manufacturing costs, and long fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

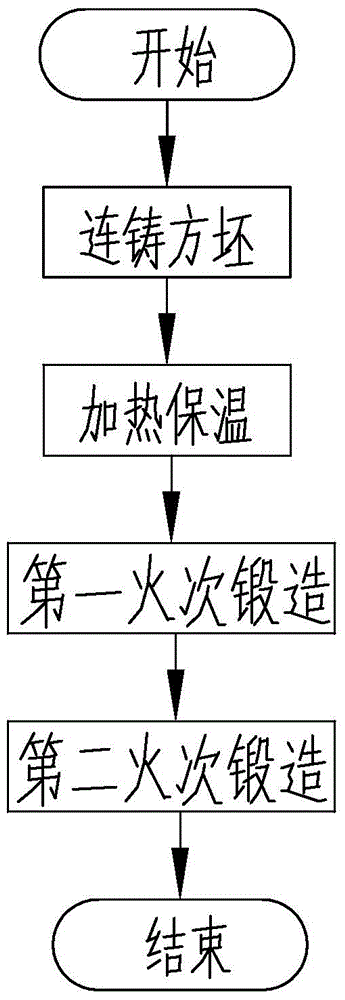

[0019] see figure 1 , a billet making method for 42CrMoA shaft forgings, comprising the following steps:

[0020] The first step, continuous casting billet: continuous casting billet by continuous casting; among them, 42CrMoA pouring molten steel is obtained by the combination of ladle refining method and vacuum degassing method; the gas content in the billet meets the following requirements: hydrogen≤1.5ppm , Nitrogen≤70ppm, Oxygen≤20ppm; the content of non-metallic inclusions in the billet conforms to the following requirements according to the GB / T10561 standard rating: Class A fine ≤ 2.5, Class A coarse ≤ 2.0; Class B fine ≤ 2.0, Class B Coarse≤1.5 grade; C type fine≤1.0 grade, C type coarse≤1.0 grade; D type fine≤1.5 grade, D type coarse≤1.0 grade; DS type≤1.0 grade;

[0021] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com