Desulfurizing agent and application thereof as well as molten iron krypton (KR) desulfurization method

A desulfurizer and molten iron technology, applied in the desulfurization field of desulfurizer and molten iron KR method, can solve the problems of unsuitable vanadium-containing molten iron, and achieve obvious environmental protection and economic effects, high desulfurization efficiency, and reduced iron inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

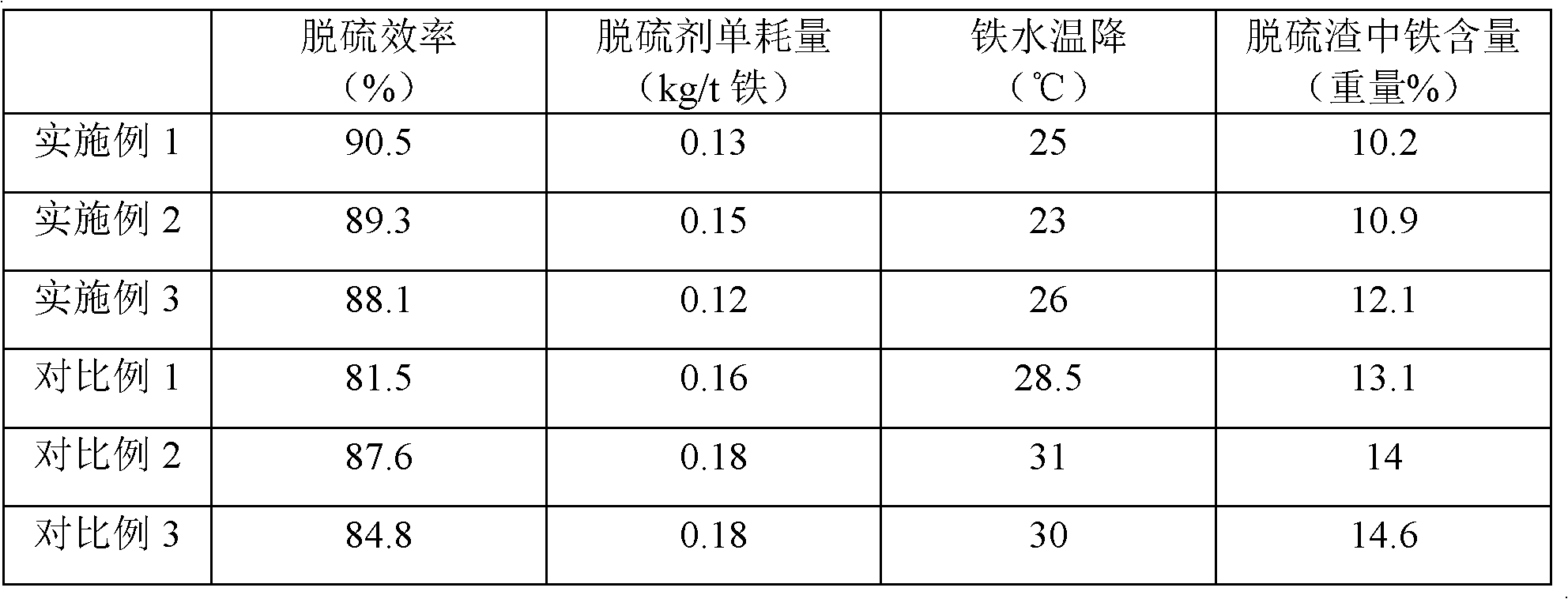

Examples

preparation example Construction

[0024] The preparation method of the desulfurizer of the present invention is to grind lime, fluorite, calcium carbide, soda ash and aluminum ash into a powder of ≤2mm, and mix them in proportion. Those skilled in the art should understand that calcium carbide is contained in the desulfurizer, and calcium carbide is easy to deliquescence when exposed to water or air, so during preparation, storage and transportation, contact with water should be avoided as much as possible, for example, when the raw materials of each component are mixed uniformly in proportion , packed in a woven bag with a waterproof inner lining, sealed and packaged, unpacked and placed in a nitrogen-sealed silo when in use.

[0025] When the desulfurizing agent of the present invention is in use, the desulfurizing agent is opened and loaded into a high-level silo, and the air is isolated with dry nitrogen. After the stirring head is completely immersed in molten iron and stirring is started, the desulfurizin...

Embodiment 1

[0047] Lime (content of calcium oxide is 85% by weight), fluorite (content of calcium fluoride is 85% by weight), calcium carbide (content of calcium carbide is 85% by weight), aluminum ash (content of aluminum is 25% by weight) , the content of Al2O3 is 30% by weight) and soda ash (the content of sodium carbonate is 98% by weight) and ground into a powder with a particle diameter≤2mm, and then put it into the mixture in a mass ratio of 35:20:20:15:10 Mix and stir in the sand machine, and get the desulfurizer after stirring evenly, put it into a sealed package with a waterproof lining woven bag, transport it to the production workshop, unpack it and put it into a nitrogen-sealed silo. After the vanadium-containing molten iron enters the desulfurization station, the scum on the surface of the molten iron is removed to expose the molten iron. After the slag is removed, 75% of the molten iron on the surface of the molten iron in the tank is exposed by visual inspection. The sulfur...

Embodiment 2

[0049] Lime (content of calcium oxide is 90% by weight), fluorite (content of calcium fluoride is 80% by weight), calcium carbide (content of calcium carbide is 80% by weight), aluminum ash (content of aluminum is 20% by weight) , the content of aluminum oxide is 50% by weight) and soda ash (the content of sodium carbonate is 98% by weight) and ground into a powder with a particle diameter of ≤2mm, and then put it into the mixture in a mass ratio of 30:18:22:20:8 Mix and stir in the sand machine, and get the desulfurizer after stirring evenly, put it into a sealed package with a waterproof lining woven bag, transport it to the production workshop, unpack it and put it into a nitrogen-sealed silo. After the vanadium-containing molten iron enters the desulfurization station, the scum on the surface of the molten iron is removed to expose the molten iron. After the slag is removed, 75% of the molten iron on the surface of the molten iron in the tank is exposed visually. The sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com