Manufacture method for cold-crack and high sensibility ultra-thick steel plate

A technology of extra-thick steel plate and production method, which is applied in the field of metallurgy, can solve the problems of single application field, etc., and achieve the effects of simple production process, wide preheating temperature range and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

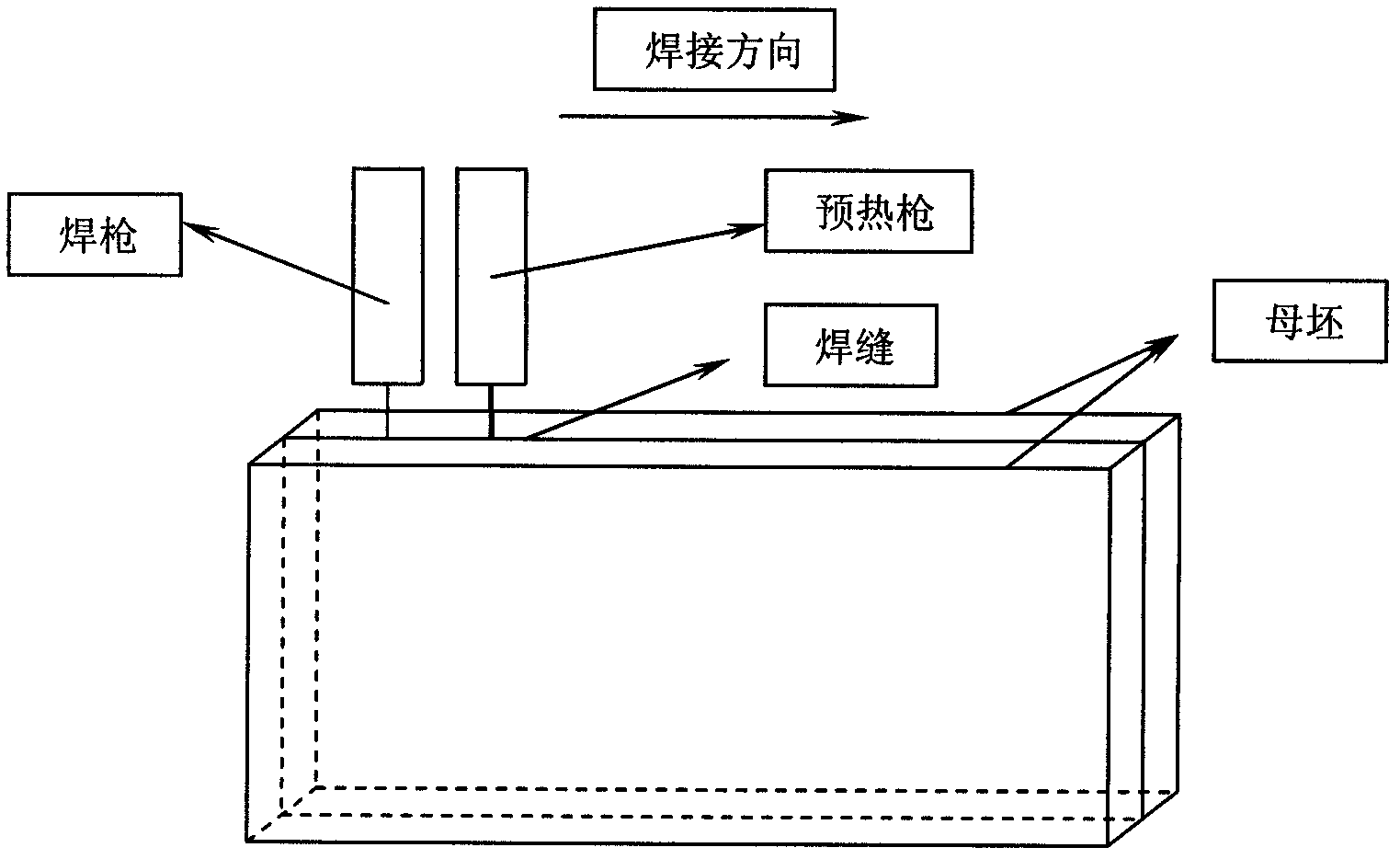

Image

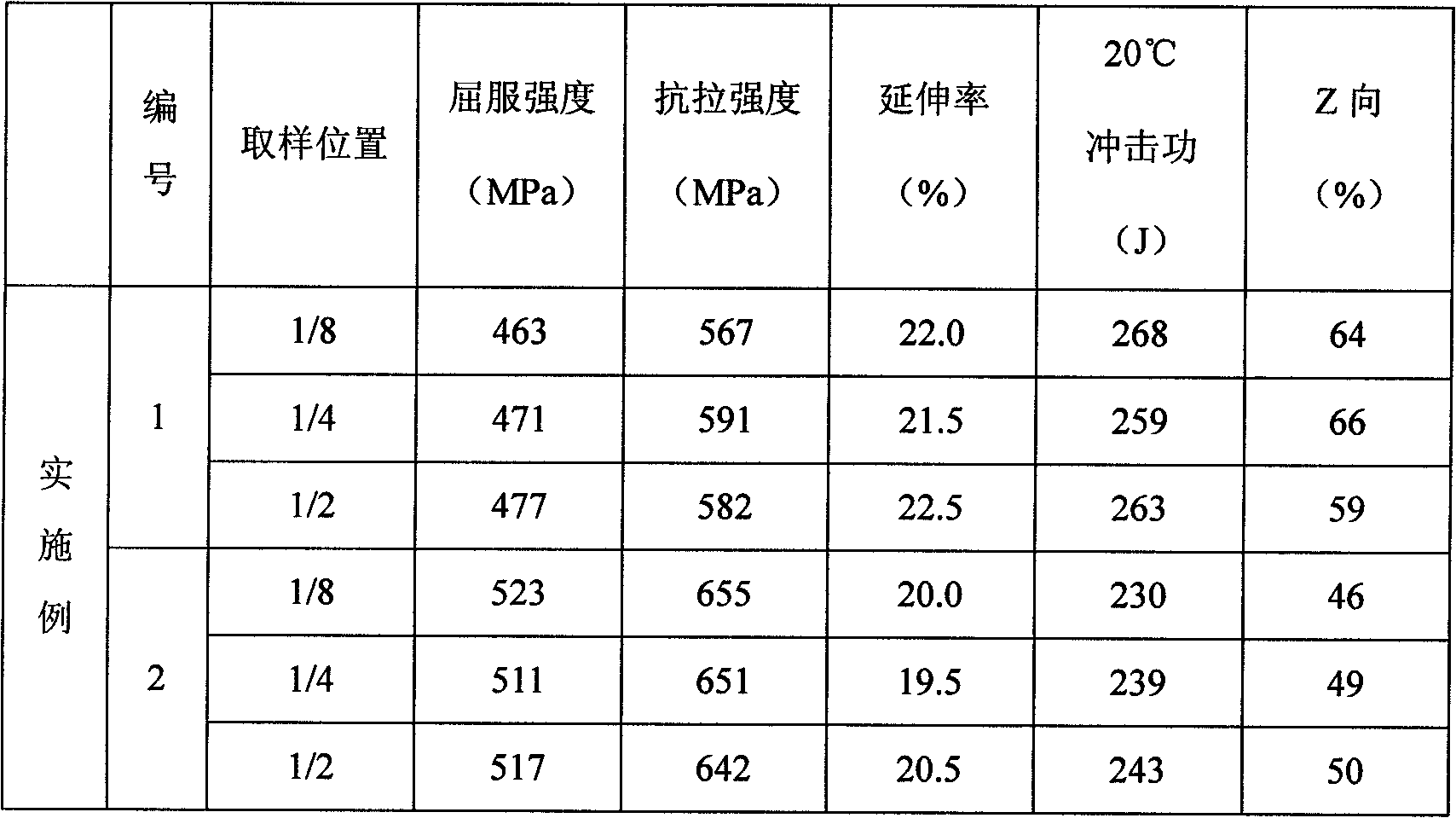

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is described in further detail:

[0019] 1. 12Cr2Mo1R steel is a steel used in the manufacture of special equipment such as hydrogenation reactors and high-pressure heat exchangers. Due to the high carbon content of this steel and the large content of alloying elements, the carbon equivalent is very large, and the finished steel plate is required. The thickness is very large, and it is easy to produce cold cracks during welding, so it must be preheated before welding. In this embodiment, two continuous casting slabs are selected for surface treatment. The welding surface is the outer arc surface of the continuous casting slab, with a roughness of 6.3 μm or more, a side surface of 12.5 μm, and a flatness of 0.8 mm / mm. 2 , and then align the welding surfaces of two blanks with a thickness of 250mm, a length of 4000mm and a width of 2300mm and push them into the vacuum chamber for preheating welding. Vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com