Metal powder preparation device and preparation method

A technology for preparing device and metal powder, applied in the field of powder metallurgy, can solve the problems of wide powder particle size distribution, large average particle size of powder, affecting powder quality, etc., and achieve the effect of narrow particle size distribution, stable product quality and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

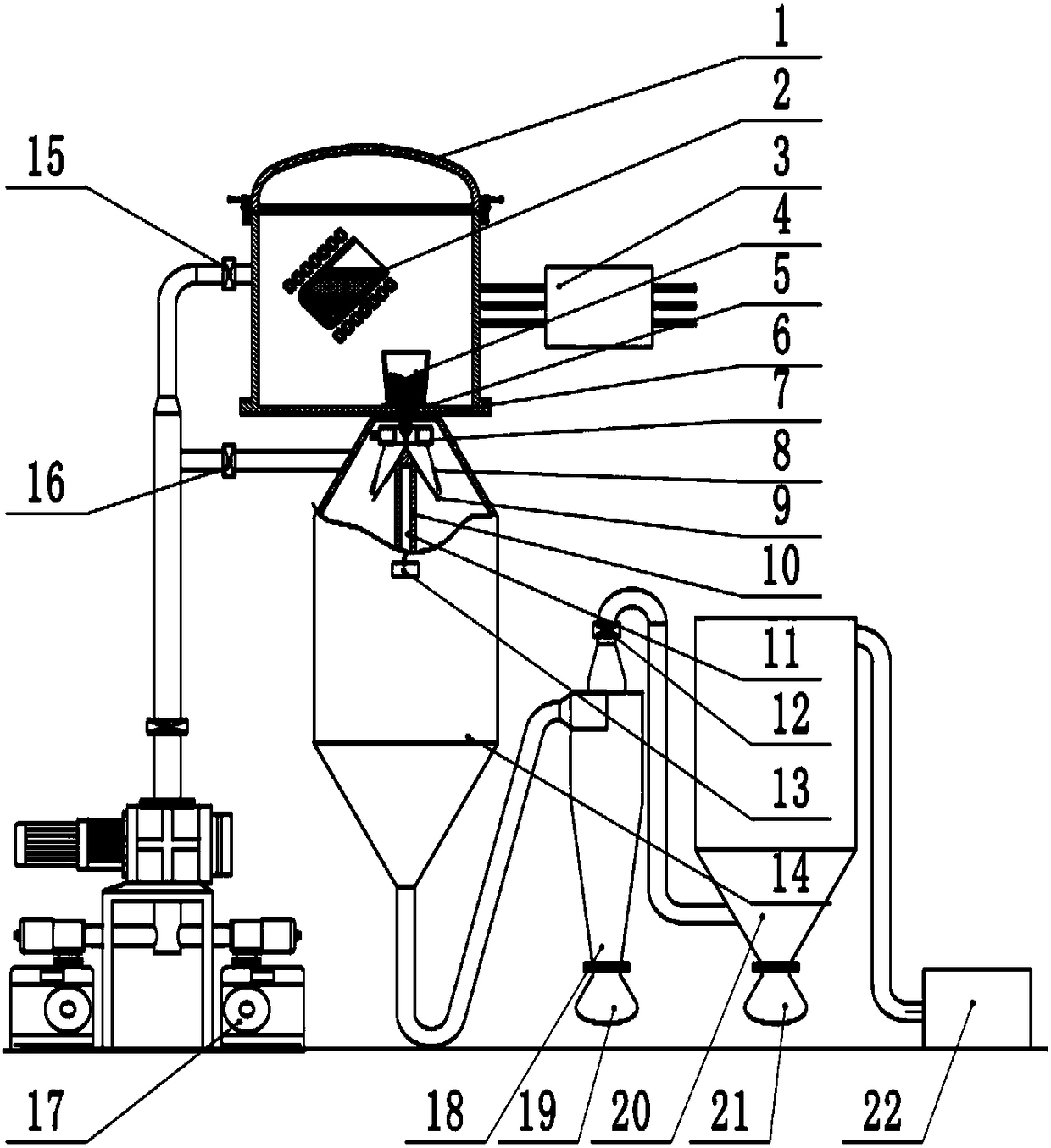

[0052] Example 1 Production of 316L stainless steel powder for 3D printing

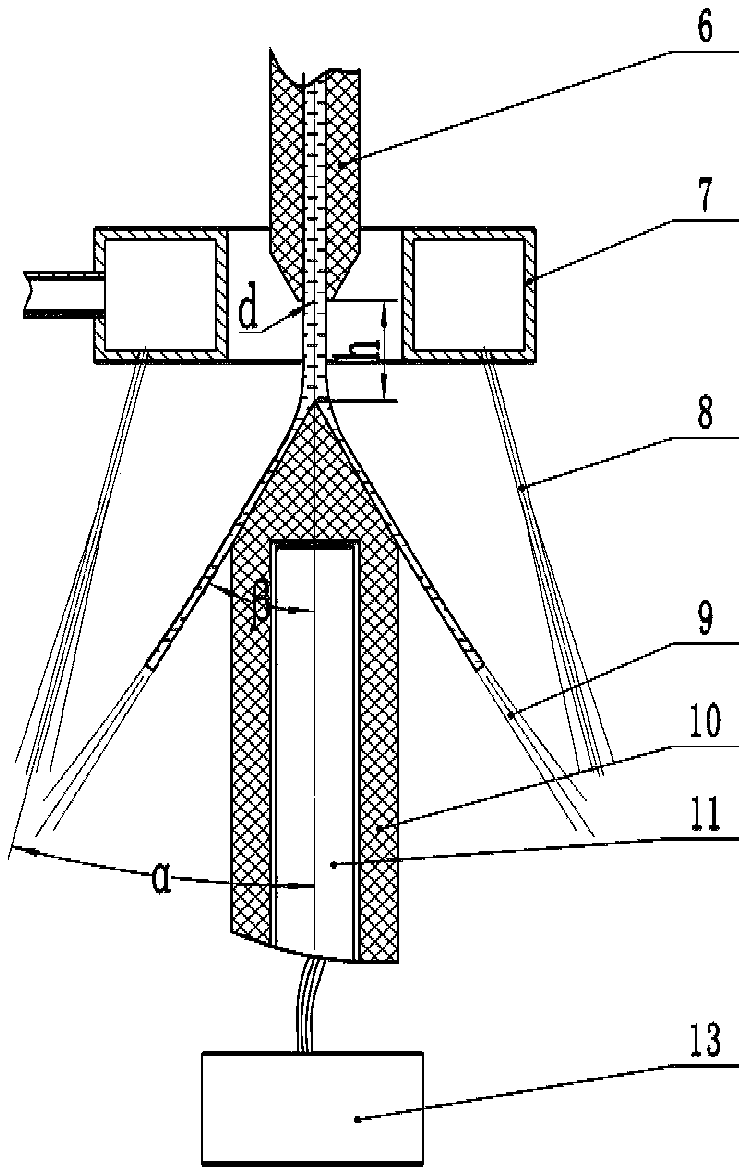

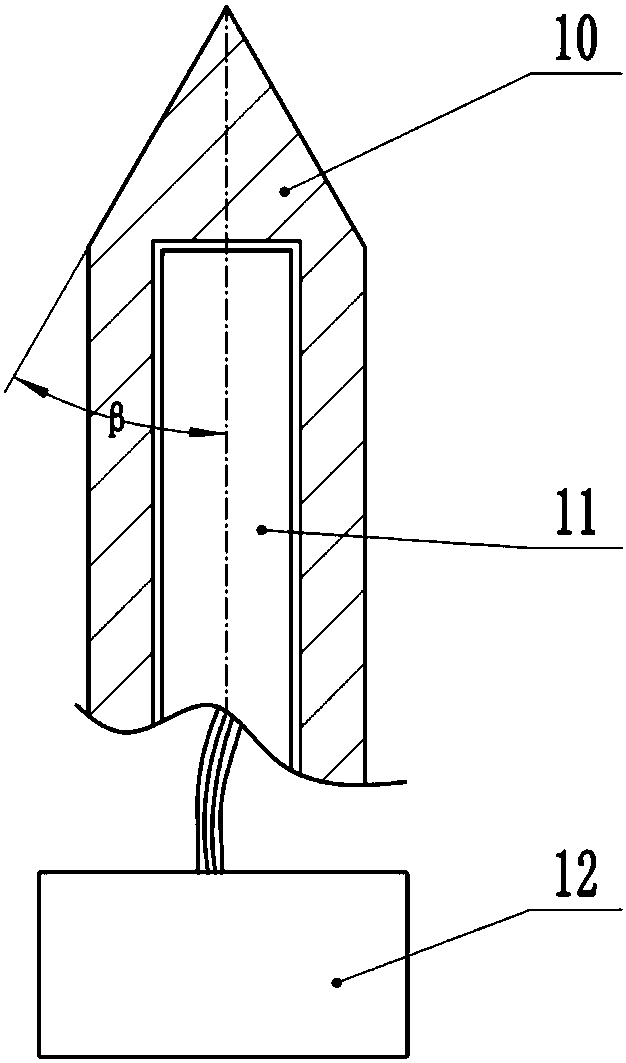

[0053] In the equipment used in this embodiment, the gas atomizing nozzle 7 is an annular nozzle, and the angle α between the center line of the spraying nozzle and the center line of the gas atomizing nozzle 7 is 35°. The diameter d at the outlet of the inner hole of the nozzle 6 is 5 mm. The distance h between the top of the melt disperser 10 and the bottom surface of the nozzle 6 is 30 mm; the top surface of the melt disperser 10 is conical, and the angle β between the generatrix of the cone surface and the center line of the cone surface is 45°. The portion of the melt disperser 10 that is in contact with the melt, that is, the tapered portion, is made of boron nitride.

[0054] The specific production of 316L stainless steel powder includes the following steps:

[0055] S1: Furnace loading, put 80KG metal into the smelting ladle 2 according to the designed ratio;

[0056] S2: prepare the atmos...

Embodiment 2

[0060] Embodiment 2 Production of copper-phosphorus welding powder for brazing

[0061] In the equipment used in this embodiment, the gas atomizing nozzle 7 is an annular nozzle with 20 nozzle holes, and the angle α between the centerline of the nozzle hole and the centerline of the gas atomizing nozzle 7 is 30°. The diameter d at the outlet of the inner hole of the nozzle 6 is 6 mm. The distance h between the top of the melt disperser 10 and the bottom surface of the nozzle 6 is 46 mm; the top surface of the melt disperser 10 is conical, and the angle β between the generatrix of the cone surface and the center line of the cone surface is 55°. The portion of the melt disperser 10 that is in contact with the melt, that is, the tapered portion, is made of alumina.

[0062] The specific production of copper phosphorous welding powder includes the following steps:

[0063] S1: Furnace loading, put 90KG metal into the smelting ladle 2 according to the designed ratio;

[0064] S2...

Embodiment 3

[0068] Example 3 Production of tin powder

[0069] In the equipment used in this embodiment, the gas atomizing nozzle 7 is an annular nozzle with 10 nozzle holes, and the angle α between the centerline of the nozzle hole and the centerline of the gas atomizing nozzle 7 is 45°; The diameter d at the outlet of the inner hole is 2mm. The distance h between the top of the melt disperser 10 and the bottom surface of the flow nozzle 6 is 60mm; the top surface of the melt disperser 10 is a concave curved surface conical shape, and the bottom of the conical surface is in the shape of a tangent along the direction of the generatrix and the center line of the conical surface. The angle β is 80°; the part of the melt disperser 10 in contact with the melt, that is, the conical part, is made of titanium.

[0070] The method for preparing metal powder by using the device for preparing metal powder comprises the following steps:

[0071] S1: Furnace loading, put 85KG metal into the smeltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com