Blowing-out descending stockline control method for blast furnace

A control method and technology of empty material line, applied in blast furnace, blast furnace details, furnace and other directions, can solve problems such as poor accuracy, inability to accurately grasp the height of material surface, and multiple inflection points of gas, and achieve the effect of rapid furnace shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The new 3# blast furnace of a certain steel plant is shut down by using the blast furnace shut down empty material line control method according to the exemplary embodiment of the present invention. The capacity of the new 3# blast furnace is 2000m 3 .

[0026] According to the method of the present invention, the first demarcation point is located at the bosh position, and the volume of the bosh above the first demarcation point accounts for 55% to 65% of the total volume of the bosh. Here, the bosh volume above the first demarcation point is taken as Accounting for 55% of the total volume of the bosh, the calculation shows that the first dividing point is at the position where the depth of the material line is -22.4m. According to the method of the present invention, the second boundary point between the coke excess process and the air oxygen excess process is located at a position 0.5-0.8m above the tuyere, here, the second boundary point is located at a position 0....

Embodiment 2

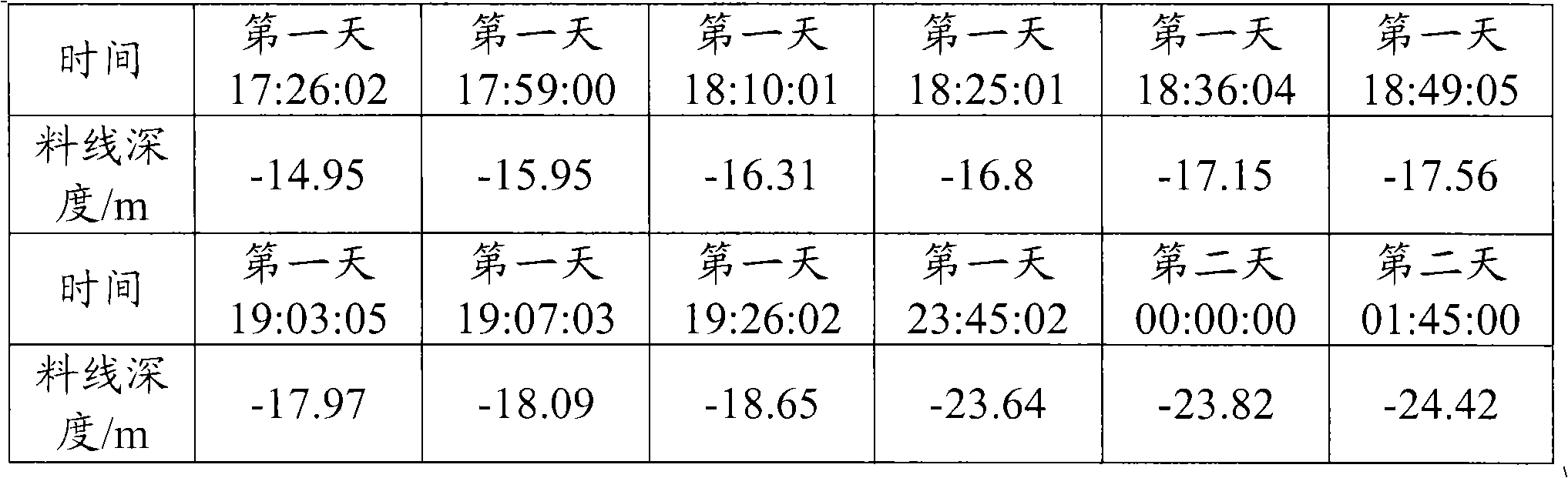

[0030] The situation of this embodiment is basically the same as that of Example 1. This embodiment is based on the amount of oxygen blown into the blast furnace, the relationship between the amount of oxygen blown into the blast furnace and the consumption of coke in the charge, the volume relationship between the coke in the charge and the charge, and the initial value of the empty charge line. The real-time depth of the material line is calculated based on parameters such as the position of the material line and the type of the blast furnace.

[0031] Make statistics on the size of the blast furnace, the feeding situation of the empty material in the previous period before the shutdown of the furnace, and the physical and chemical properties of the raw materials (composition, stack specific gravity, etc.). In this embodiment, in the process of reducing ore, the K value representing the relationship between the amount of oxygen blasted into the blast furnace and the consumpti...

Embodiment 3

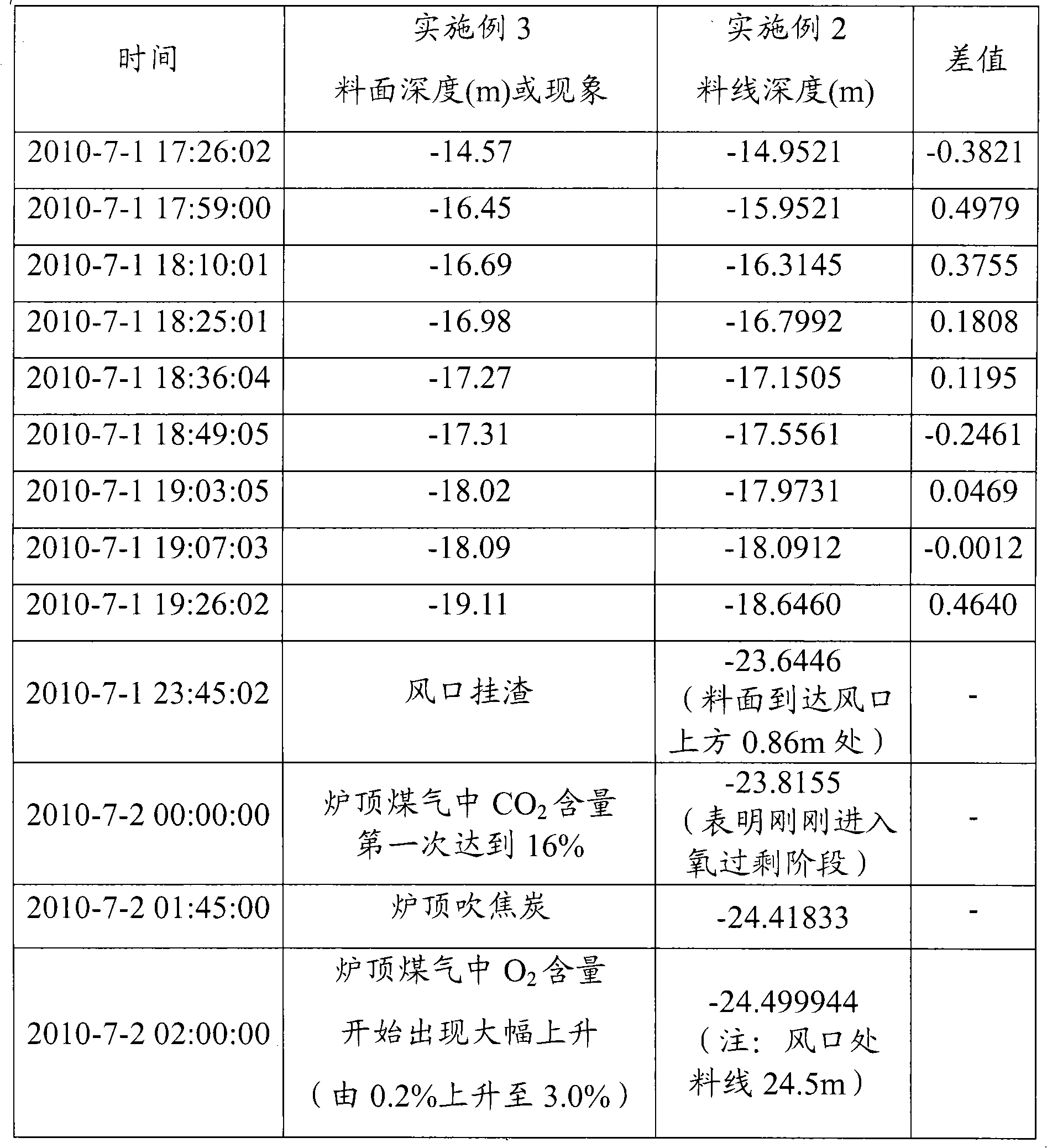

[0036] The situation of this embodiment is basically the same as that of Embodiment 1. In this embodiment, the following auxiliary methods are used to determine the position of the material line: in the early stage of the empty material line, the depth of the material line fed back by lengthening the probe is used; Changes in gas composition, coke blowing from the top of the furnace, and slag hanging from the tuyere to determine the approximate location.

[0037] Here, the real-time material line depth value measured with the extended probe in Example 3 is compared with the real-time material line depth value calculated in Example 2, and the results are shown in Table 2.

[0038] Table 2 embodiment 2 and embodiment 3 real-time material line depth value contrast

[0039]

[0040] It can be seen from Table 2 that the difference between the real-time material line depths measured in Examples 2 and 3 fluctuates between ±0.5m, which meets the required error range. It can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com