Blast furnace shutdown method

A blast furnace and furnace adjustment technology, which is applied in the field of blast furnace smelting to achieve the effect of rapid furnace shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

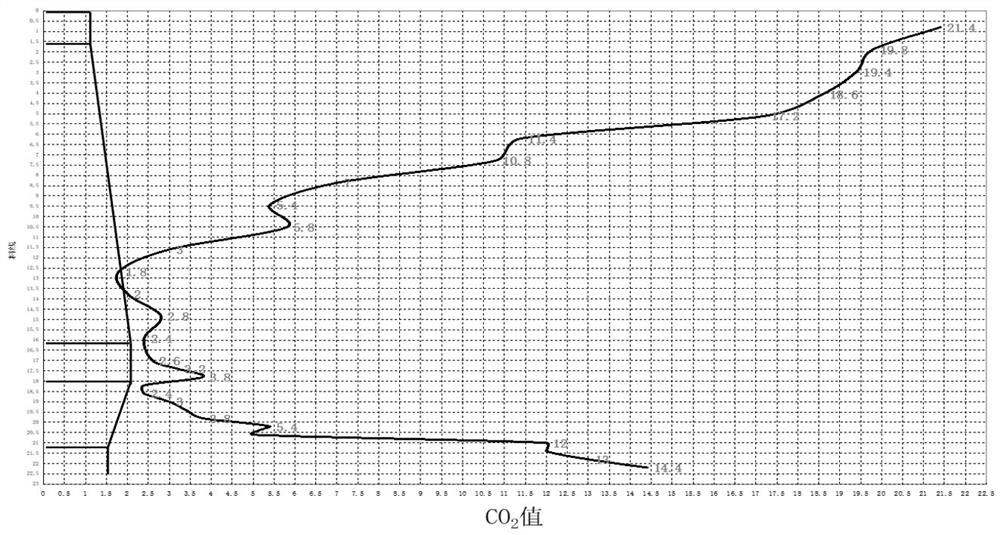

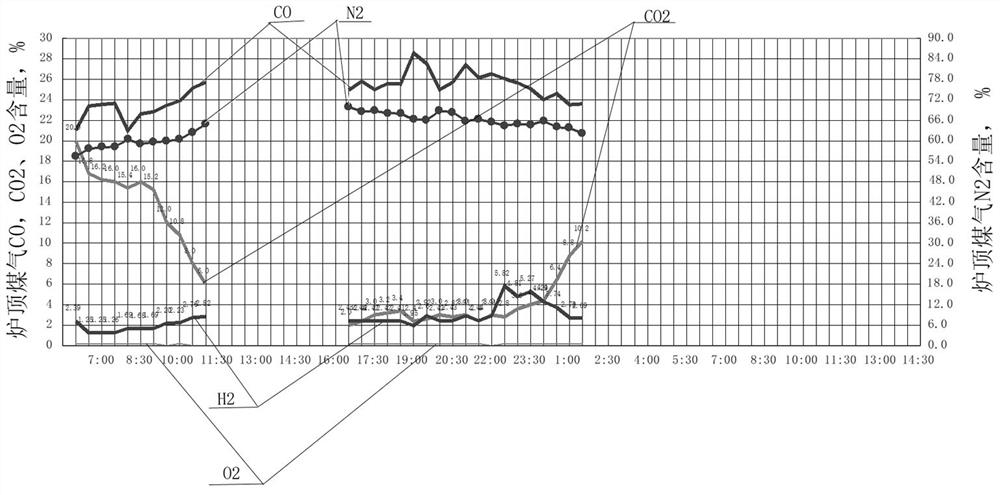

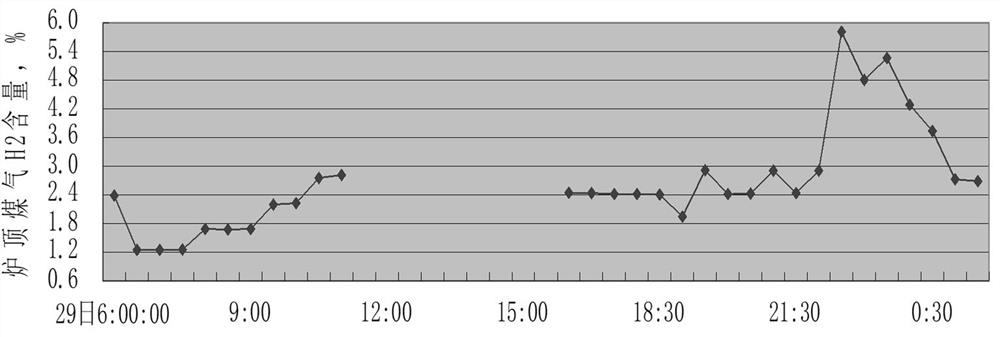

[0014] During the blast furnace shutdown process, it is estimated that the material line is 10.0-13.5m after the pre-shutdown air. After the blast furnace is supplied, the amount of water on the top of the furnace is adjusted according to the direction of the furnace top temperature, and the unidirectional furnace top temperature during the shutdown process is controlled to be ≮95 ℃, to prevent the temperature in this direction from being too low, the condensed water will flow down the blast furnace skin and reach the high temperature zone in the lower part of the blast furnace, where it will decompose to generate hydrogen and peroxygen and cause an explosion. The furnace top gas was measured by manual, online analyzer and spectrometer every 0.5h, and analyzed by comparison. During the shutdown process, the air volume is reduced or adjusted according to the pressure difference in the furnace and the air permeability index, so as to prevent the pipeline from being blown out unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com