Furnace halt residue iron outlet method for middle and large-sized blast furnaces

A technology of residual iron and blast furnace, which is applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., to achieve the effect of reducing manpower and quickly shutting down the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can shorten the total shutdown time by 2 hours by adopting two residual iron ports when the medium and large blast furnace is shut down, and the deposits in the hearth are greatly reduced after the shutdown (mainly condensed iron) reduced), and the amount of residual iron produced increased, the actual iron produced was closer to the theoretical iron produced, and the time for cleaning the deposits in the hearth after the furnace was shut down was shortened from 7 days to 3 to 4 days. Shorten the maintenance period to create favorable conditions. Here, it should be pointed out that the residual iron port refers to the outlet used to discharge residual iron on the blast furnace.

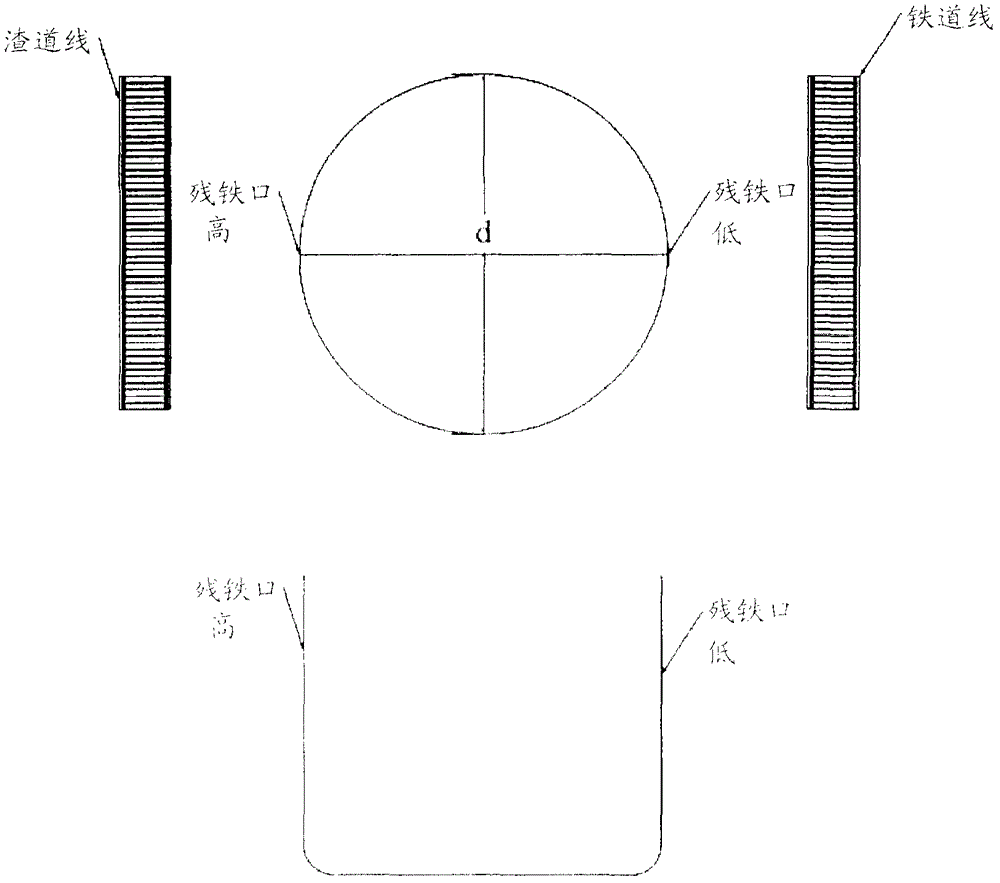

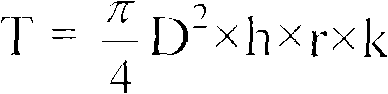

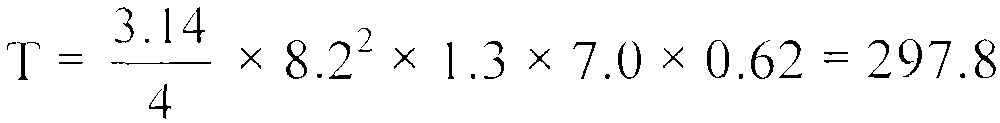

[0015] The following will refer to figure 1 Describe in detail the method for shutting down a medium-to-large blast furnace to remove residual iron according to the present invention. figure 1 It is a schematic diagram of determining the position of the residual iron gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com