Internal combustion engine exhuast gas post treatment method and apparatus for executing same

A technology of exhaust gas post-treatment and internal combustion engine, which is applied in the direction of electric control of exhaust treatment devices, exhaust devices, exhaust treatment, etc., can solve the problems of not being reliably reached, and achieve good exhaust gas purification and rapid heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

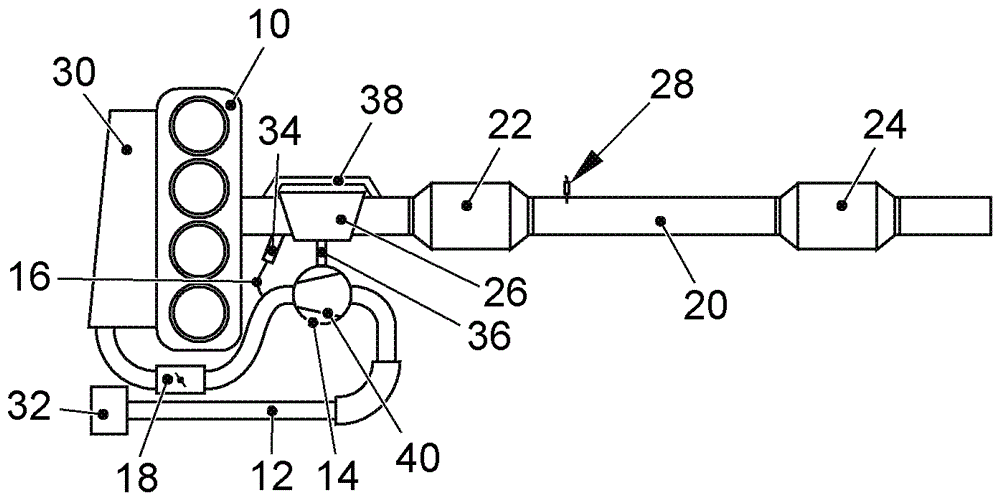

[0052] figure 1 A superchargeable externally ignited internal combustion engine 10 , preferably a turbocharged Otto engine, is shown with a fresh air duct 12 and an exhaust gas duct 20 . Arranged in the exhaust gas duct 20 in the flow direction of the exhaust gas of the internal combustion engine 10 is a turbine 26 which is connected via a drive shaft 36 to the compressor 14 in the fresh air duct 12 . Turbine 26 and compressor 14 are part of turbocharger 40 . Downstream of the turbine 26 , a three-way catalytic converter 22 is arranged in the exhaust gas duct 20 , preferably close to the engine. A bypass channel 38 , in particular a so-called wastegate, is formed on the turbine 26 , with which a partial flow of exhaust gas can be guided past the turbine 26 . The bypass channel 38 can be closed by a valve or valves (not shown). Downstream of the three-way catalytic converter 22 , a particle filter 24 is arranged in the exhaust gas duct 20 , which is preferably arranged in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com