Method for producing low nickel matte by smelting, reducing and vulcanizing nickel oxide ore

A technology for nickel oxide ore and nickel matte, applied in the field of nickel oxide ore smelting, can solve the problems of large installed load and high energy consumption of electric furnaces, and achieve the effects of small load, high vulcanization efficiency and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

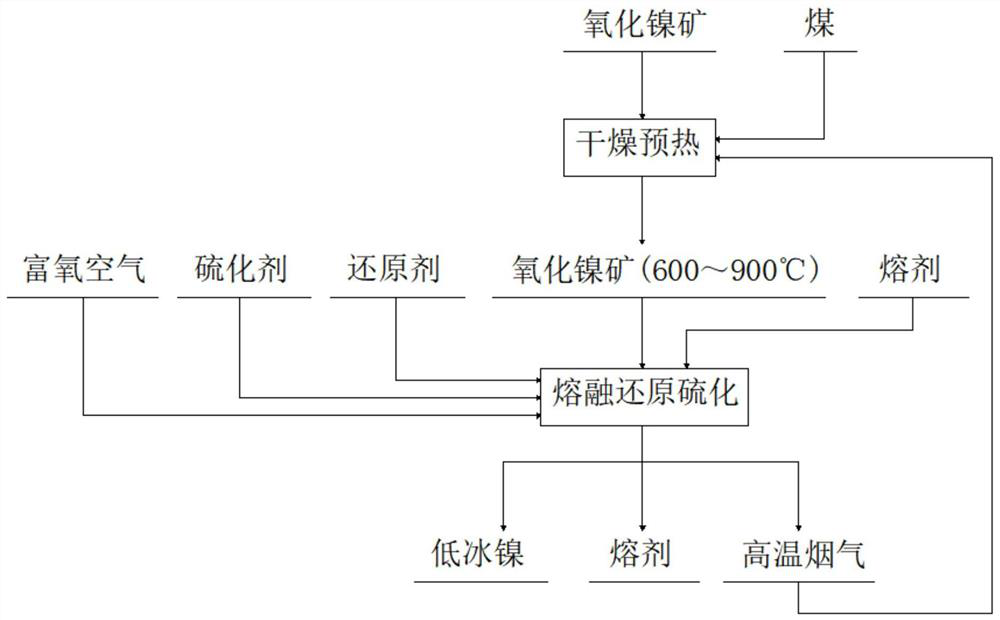

Method used

Image

Examples

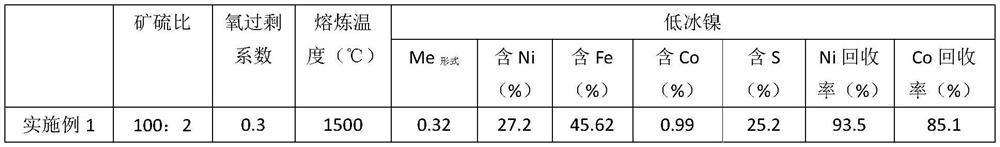

Embodiment 1

[0053] The nickel oxide ore is dried and preheated in a rotary kiln, and the output temperature is 600 ℃ hot nickel oxide ore. The hot material produced by drying and preheating is screened by a grid, and the undersize is controlled to be less than 50mm. According to the ratio of nickel oxide ore: calcium carbonate = 10:1, the hot nickel oxide ore and the flux calcium carbonate are continuously added to the oxygen-rich molten pool smelting furnace from the furnace top, and at the same time according to nickel oxide ore: pulverized coal: sulfur = 100:18 : 2, inject the reducing agent pulverized coal and vulcanizing agent sulfur into the reaction area of the molten pool through the furnace body, and inject oxygen-enriched air with an oxygen concentration of 85% at the same time, the oxygen-enriched air pressure is 0.2Mpa, and the oxygen excess coefficient is 0.3; Oxygen-enriched air with an oxygen concentration of 60% is injected into the upper gas phase space of the melt in th...

Embodiment 2

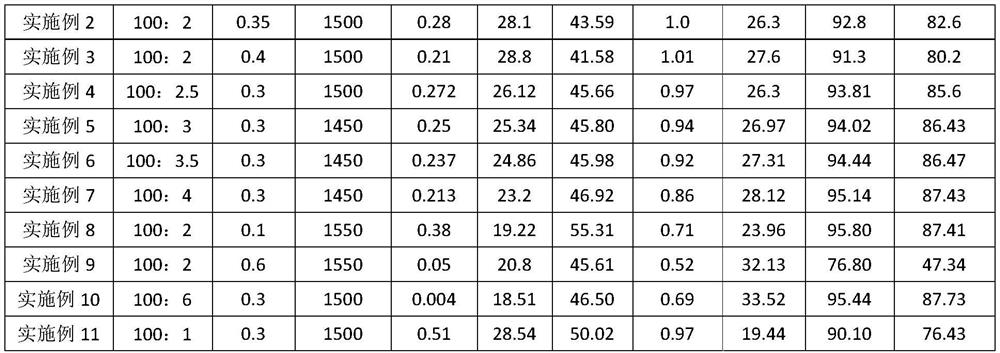

[0055] Compared with Example 1, other parameters are the same as in Example 1 except that the oxygen excess coefficient is controlled to be 0.35, which will not be repeated here. The sulfur content is 26.3%, the nickel metal recovery rate is 92.8%, the cobalt metal recovery rate is 82.6%, and the low matte metallization rate is 0.28. Reduced sulfide slag contains NiO: 0.12%, FeO: 17.37%, SiO 2 : 35.79%, CaO: 5.62%, MgO: 22.31%, Al 2 O 3 : 4.45%. The reduced sulfide fume is granulated and returned to smelting. Low nickel matte is intermittently released, and slag is continuously released for water quenching. The smelting flue gas enters the rotary kiln through the flue to dry and preheat the nickel oxide ore. The flue gas discharged from the outlet of the rotary kiln is dedusted by the bag filter and sent to the desulfurization system, so that the sulfur dioxide content in the flue gas meets the national emission standard.

Embodiment 3

[0057] Compared with Example 1, except that the oxygen excess coefficient is controlled to be 0.4, other parameters are the same as those of Example 1, which will not be repeated here. The low matte nickel produced by the reaction contains 28.8% nickel, 1.01% cobalt, and 41.58% iron. The sulfur content is 27.6%, the nickel metal recovery rate is 91.3%, the cobalt metal recovery rate is 80.2%, and the low matte metallization rate is 0.21. The reduced sulfide slag contains NiO: 0.13%, FeO: 17.52%, SiO 2 : 35.73%, CaO: 5.61%, MgO: 22.71%, Al 2 O 3 : 4.36%. The reduced sulfide fume is granulated and returned to smelting. Low nickel matte is intermittently released, and slag is continuously released for water quenching. The smelting flue gas enters the rotary kiln through the flue to dry and preheat the nickel oxide ore. The flue gas discharged from the outlet of the rotary kiln is dedusted by the bag filter and sent to the desulfurization system, so that the sulfur dioxide con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com