Suspension roasting comprehensive utilization system and method for iron containing manganese ore

A technology of suspension roasting and manganese ore, which is applied in the field of mineral processing, can solve the problems of inability to realize efficient comprehensive utilization of iron-manganese ore resources, low processing capacity, and high energy consumption, and achieve recyclable waste heat, large processing capacity, and high heat and mass transfer efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

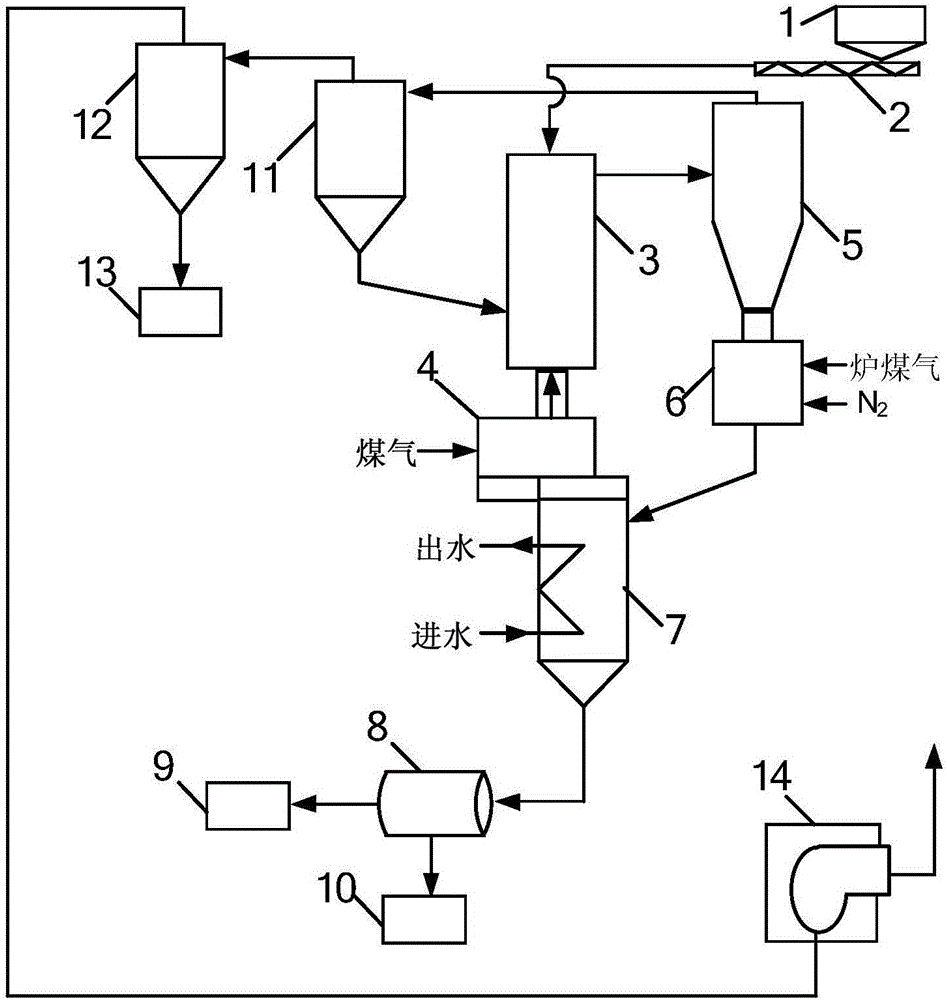

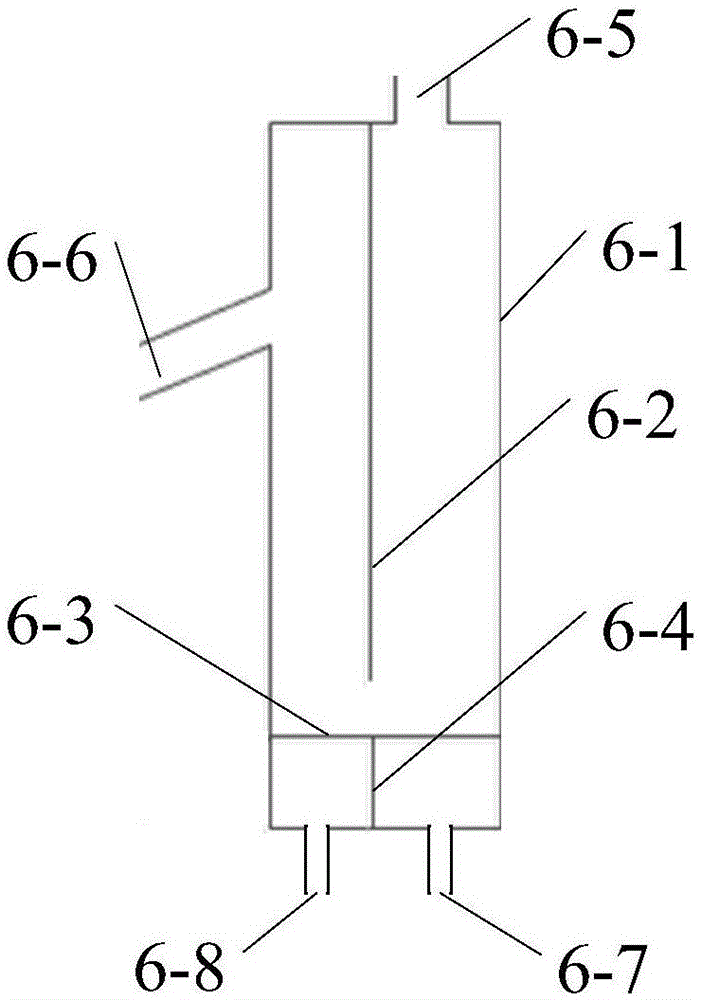

[0044] The structure of the comprehensive utilization system of suspension roasting of ferromanganese ore is as follows: figure 1 Shown, comprise feeding bin (1), cyclone separator (11), suspension roasting accumulator (3), burner (4), suspension roasting oxidizer (5), reducer (6), cooler ( 7) and magnetic separator (8); the discharge port of feeding bin (1) is communicated with the inlet of screw feeder (2), and the outlet of screw feeder (2) passes through pipeline and cyclone separator (11) The feed inlet at the top is communicated, the discharge outlet at the bottom of the cyclone separator (11) is communicated with the feed inlet below the suspension roasting accumulator (3), and the discharge outlet above the suspension roasting accumulator (3) is connected to the The feed port above the suspension roasting oxidizer (5) is connected, the feed port at the bottom of the suspension roasting oxidizer (5) is connected with the feed port of the reducer (6), and the feed port o...

Embodiment 2

[0066] System structure is the same as embodiment 1;

[0067] Method is with embodiment 1, and difference is:

[0068] (1) crushing the ferromanganese ore to a particle size of -200 mesh accounts for 65% of the total weight;

[0069] (2) The temperature of the solid material in the suspension roasting accumulator is controlled at 900°C;

[0070] (3) In the suspension roasting oxidizer, the solid material temperature is 800°C, and the residence time is 20min;

[0071] (4) The solid material is in a suspended state under the action of the furnace gas and the residence time in the discharge chamber is 10 minutes. The temperature of the material is controlled at 600 ° C. The ratio of the furnace gas to the solid material in the discharge chamber is according to CO and H 2 The total amount and Fe 2 o 3 The molar ratio is 1:2;

[0072] (5) The solid material enters the cooler, is cooled to 290°C through heat exchange, and then enters the magnetic separator for magnetic separati...

Embodiment 3

[0075] System structure is the same as embodiment 1;

[0076] Method is with embodiment 1, and difference is:

[0077] (1) crushing the ferromanganese ore to a particle size of -200 mesh accounts for 70% of the total weight;

[0078] (2) The temperature of the solid material in the suspension roasting accumulator is controlled at 1000°C;

[0079] (3) In the suspension roasting oxidizer, the solid material temperature is 900°C, and the residence time is 10 minutes;

[0080] (4) The solid material is in a suspended state under the action of the furnace gas and the residence time in the discharge chamber is 5 minutes. The temperature of the material is controlled at 700 ° C. The ratio of the furnace gas to the solid material in the discharge chamber is according to CO and H 2 The total amount and Fe 2 o 3 The molar ratio is 1:2;

[0081] (5) The solid material enters the cooler, is cooled to 280°C through heat exchange, and then enters the magnetic separator for magnetic sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com