Heat accumulation type waste liquid combustor

A burner and regenerative technology, which is applied in the field of regenerative waste liquid burners, can solve the problems of secondary environmental pollution, unsatisfactory incineration effect, difficult atomization and gasification of organic waste, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

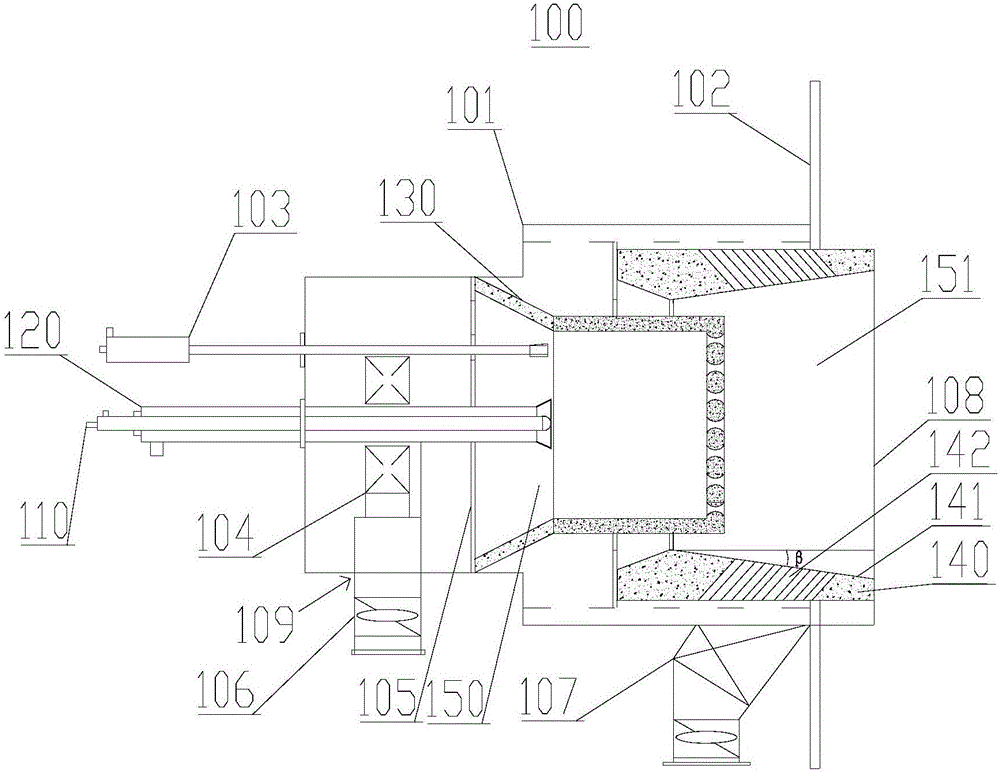

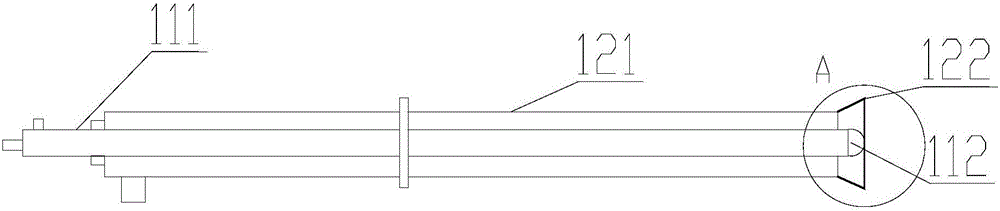

[0018] figure 1 It is a schematic diagram of the structure of the regenerative waste liquid burner 100 provided by the embodiment of the present invention, please refer to figure 1 , The heat storage type waste liquid burner 100 includes a housing 101, a waste liquid atomization burner 110, a combustion nozzle 120, a heat storage vaporization cover 130 and an igniter 103. The housing 101 has an open end 108 and an outer wall of the open end 108 A flange 102 is provided, and the flange 102 at the open end 108 is used to connect with the furnace body of the waste liquid incineration device.

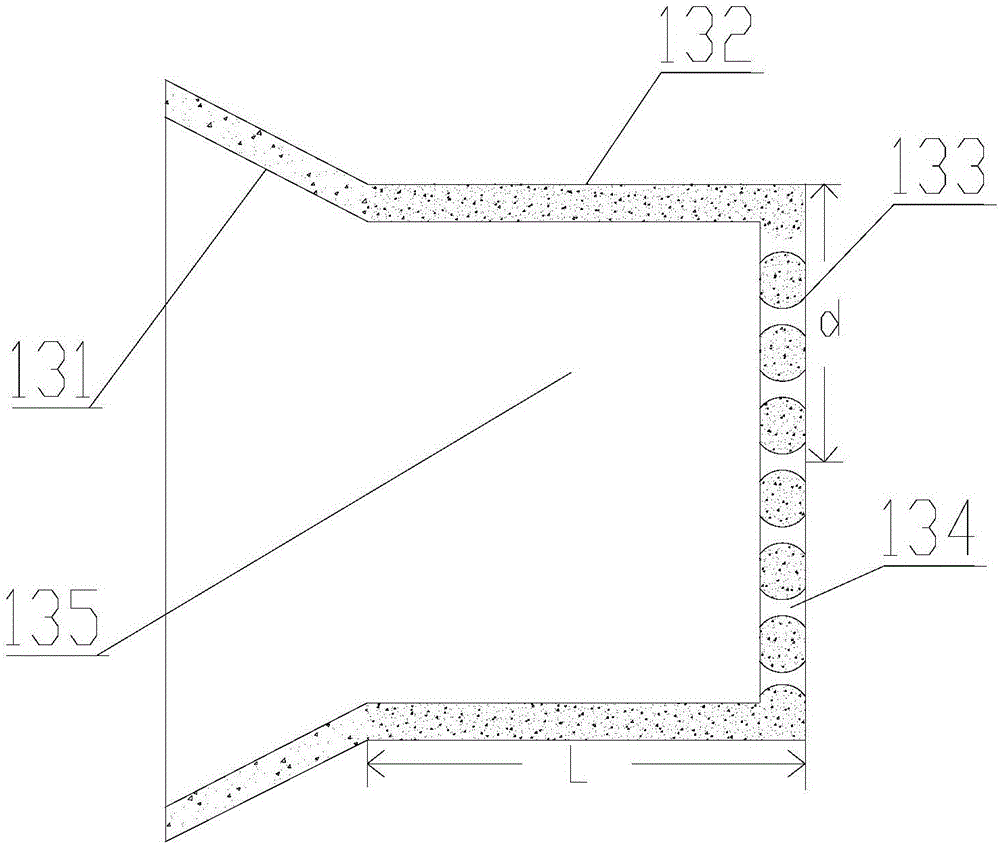

[0019] figure 2 It is a schematic diagram of the structure of the heat storage gasification cover 130 provided by the embodiment of the present invention, please refer to figure 2 The heat storage gasification cover 130 separates the housing 101 into a first combustion zone 150 far away from the open end 108 and a second combustion zone 151 close to the open end 108. Specifically, in this embo...

Embodiment 2

[0039] The regenerative waste liquid burner 100 provided in this embodiment has the same basic structure, principle and technical effect as Embodiment 1. For a brief description, for the parts not mentioned in this embodiment, please refer to Embodiment 1. Corresponding content.

[0040] Image 6 It is a schematic diagram of the structure of the regenerative waste liquid burner 100 provided in this embodiment. The difference between this embodiment and Embodiment 1 is that this embodiment can not only realize the atomization incineration of waste liquid, but also realize the incineration treatment of waste gas. In this example, please refer to Image 6 A plurality of exhaust gas burners 160 are provided in the housing 101. Each exhaust gas burner 160 includes an exhaust gas nozzle 162 and an exhaust pipe 161. The exhaust pipe 161 extends from the first combustion zone 150 through the first side wall 131 into the second combustion zone. In area 151, the exhaust gas pipe 161 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com