Sensor for measuring the total content of nitrogen oxides in mixed gas

A technology of nitrogen oxides and mixed gas, applied in the direction of material resistance, etc., can solve the problems of large interference, low-concentration NOX precision, complex sensor control process, etc., and achieve the effect of simple control process, sensitive detection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

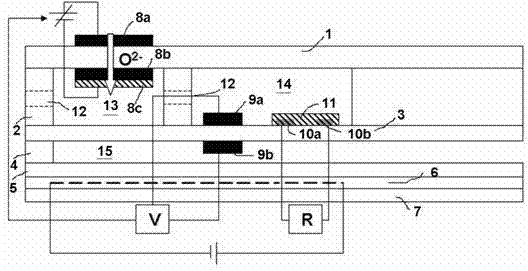

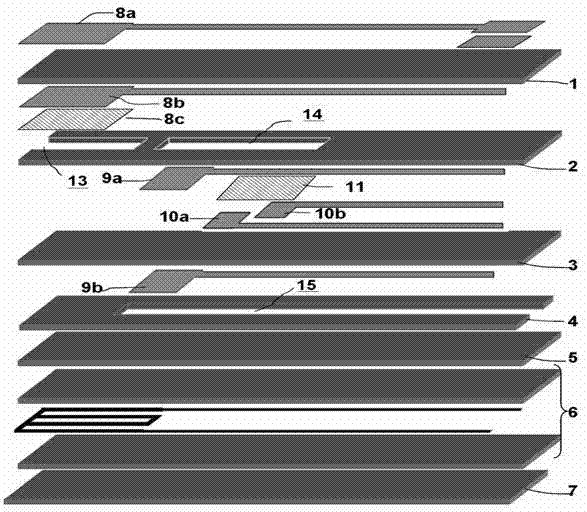

[0036] For verifying the effect of the present invention made one such as figure 1 The sensor of the structure shown. Grind zirconia yttrium powder (yttrium doping content 8mol%) and alumina balls into slurry, cast and dry to make 0.8mm thick biscuit, cut the biscuit into 200mm×200mm square, substrate The preparation method of 1 is to take a piece of cut zirconia yttrium green blank and print platinum lead wires and oxygen pump electrodes 8a, 8b on its upper and lower surfaces by screen printing. After drying, a layer of LaMnO is screen-printed on the surface of electrode 8b. 3 Slurry 8c, dry. Take another piece of cut zirconia yttrium biscuit, according to image 3 The positions shown are perforated to form the substrate 2 . The substrate 3 is to screen-print platinum lead wires and platinum oxygen-sensitive electrodes 9a, 9b on the upper and lower surfaces of the cut zirconia yttrium blank, and print gold detection electrodes 10a, 10b on the same side of the electrode 9a...

Embodiment 2

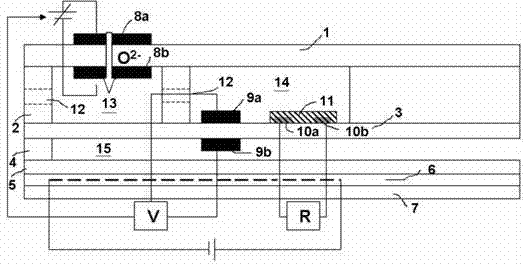

[0040] like figure 2 As shown, except that the manufacturing process of the oxygen pump electrode 8b in the first chamber is changed to screen printing a layer of platinum and LaMnO on the lower surface of the substrate 1 3 Except for the slurry prepared by mixing, the others are exactly the same as the first embodiment.

Embodiment 3

[0042] In addition to changing the detection electrode gas-sensitive material 11 in the second chamber to In 2 o 3 Other than that, it is exactly the same as the second embodiment. Catalyst In 2 o 3 As the gas sensitive material 11, in order to evaluate the effect of this change, test the sensor C in the concentration range from 10 to 500ppm of NO content, the relationship curve between resistance and NO concentration ( Figure 4 ), the experimental results are as follows Figure 4 As shown, the figure shows that the sensor C shows a more obvious resistance change than the sensor described in Example 1 under the same concentration of NO, indicating that this improvement helps to reduce the NO 2 adsorption, thereby improving the sensitivity of the sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com