Hydraulic system of loading machine working device

A technology for working devices and hydraulic systems, which is applied to earth movers/excavators, construction, etc., can solve problems such as excessive cost and large overflow loss, avoid high cost problems, reduce hydraulic system power loss, and improve The effect of power matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

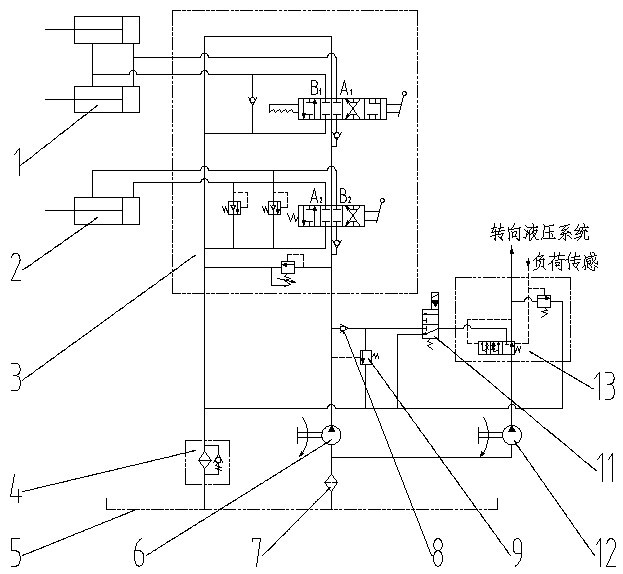

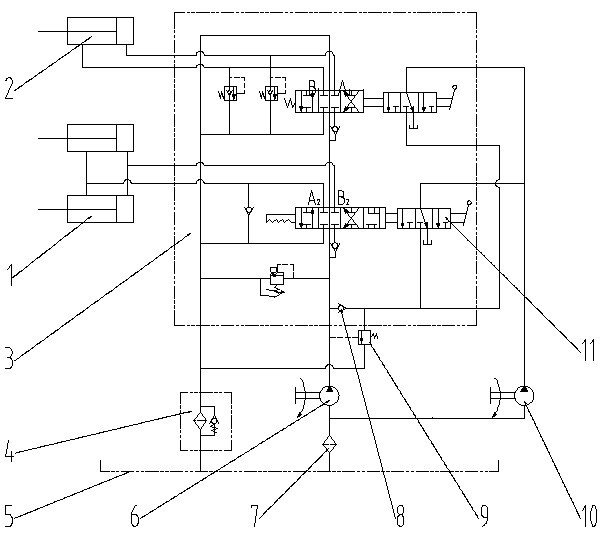

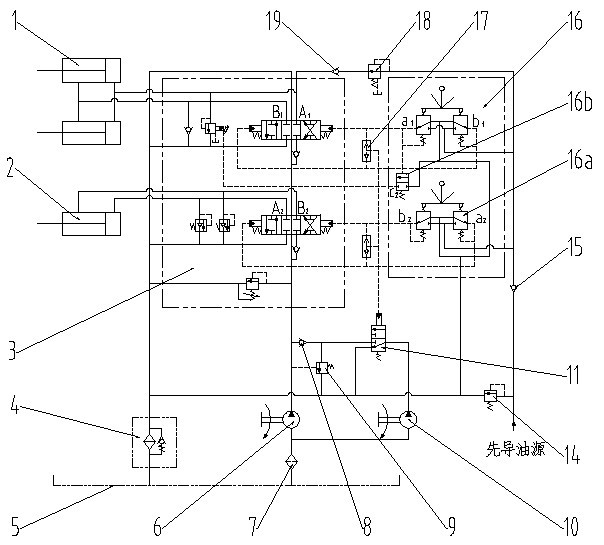

[0022] The hydraulic system principle of the loader working device of the present invention is as follows: figure 1 As shown, it consists of boom hydraulic cylinder 1, bucket hydraulic cylinder 2, multi-way reversing valve 3, oil filter 4 and 7, hydraulic oil tank 5, working pump 6, one-way valve 8, equivalent unloading valve 9, It consists of an auxiliary pump 10 and a confluence control valve 11. The working pump 6 and the auxiliary pump 10 form a dual-pump system to deliver hydraulic oil to the hydraulic system. The oil outlet of the working pump 6 is connected to the multi-way reversing valve 3, and A1 and B1 of the multi-way reversing valve 3 are respectively connected to the boom hydraulic cylinder. 1, A2 and B2 are respectively connected to the two chambers of the bucket hydraulic cylinder 2; the oil outlet of the auxiliary pump 10 is connected to the port of the confluence control valve 11P1, and the position of the spool of the confluence control valve 11 is related t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com