Electric automobile and electro-hydraulic hybrid power driving system

An electro-hydraulic hybrid and power-driven technology, which is applied in the field of electro-hydraulic hybrid drive system, two-wheel drive or four-wheel drive electric vehicles, can solve the problems of increasing battery and motor load and impact, reducing battery service life, accelerating motor power demand, etc. , to achieve the effect of improving service life and safety, avoiding impact, and meeting the requirements of high power density and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

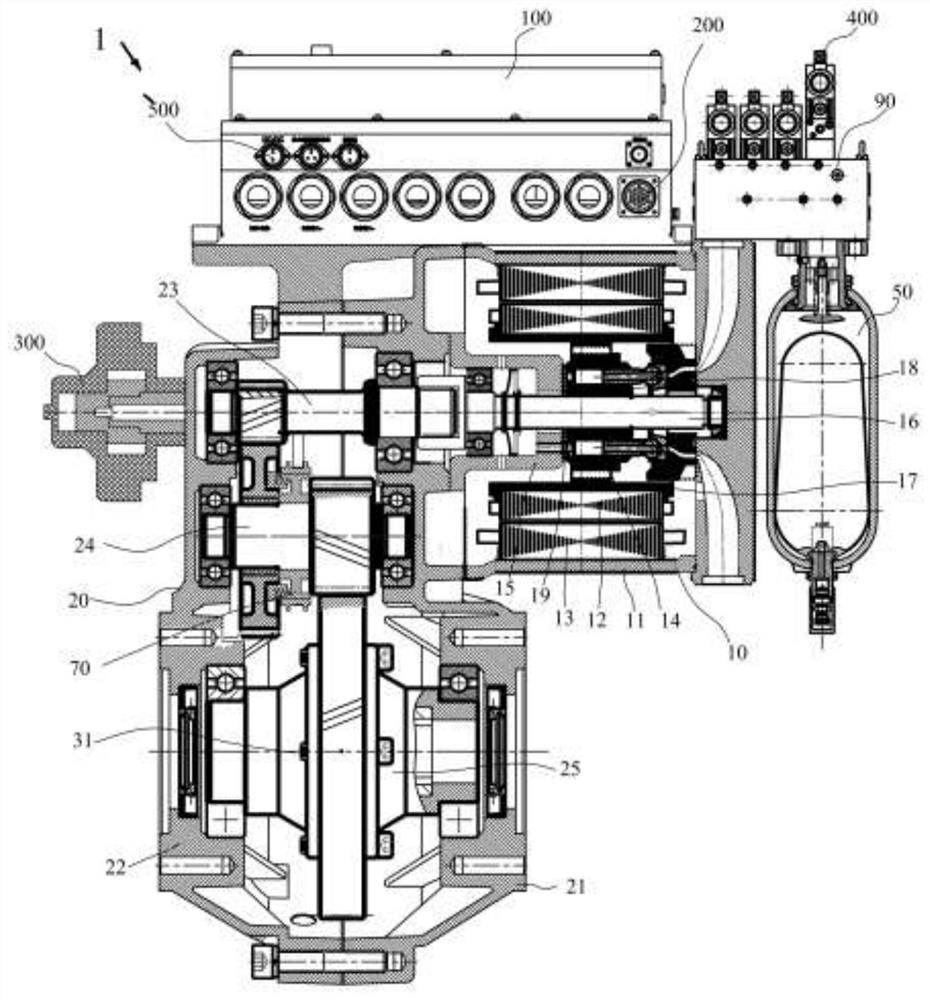

[0085] Such as image 3 As shown, an electro-hydraulic hybrid drive system 1 for electric vehicles is shown, including a central controller 100, a speed reducer 20, an electro-hydraulic integrated machine 10 connected to the speed reducer 20, and a valve group assembly 90 , an accumulator 50, the electro-hydraulic integrated machine 10 includes a motor housing assembly 11 and a motor assembly accommodated in the motor housing assembly, a first hydraulic pump / motor assembly 14, the motor assembly includes a rotor assembly 12. The stator assembly 13, the motor housing assembly 11 is provided with a valve group assembly 90, the accumulator 50 is connected to the valve group assembly 90, and the electro-hydraulic hybrid power assembly has:

[0086] a. Work in the pure electric mode, that is, fully receive the electric energy of the battery pack 110 and convert it into mechanical energy, or convert the mechanical energy into the working mode of the electric energy of the battery pa...

Embodiment 2

[0093] Such as Figure 5 As shown, an embodiment of a two-drive electric vehicle comprising the electro-hydraulic hybrid drive system is shown, which includes a battery pack 100, a drive axle 34, a differential 31, and the speed reducer 20 and the differential 31 On the reducer housing, the differential 31 is respectively connected with the left half shaft 32 and the right half shaft 33 of the driving axle 34 and drives the wheels to move, and the driving axle 34 can be in the form of driving the front axle or driving the rear axle.

[0094] Further, as Figure 8 As shown, it is a block diagram of the drive system of a two-wheel drive electric vehicle, which includes a motor controller 200, a valve group assembly controller 400, and an inverter 500. The central controller 100 connected to the battery can communicate with the external charging interface 120. connection, here also includes a charging inverter 121. For example, charging interface 120 may absorb electrical energ...

Embodiment 3

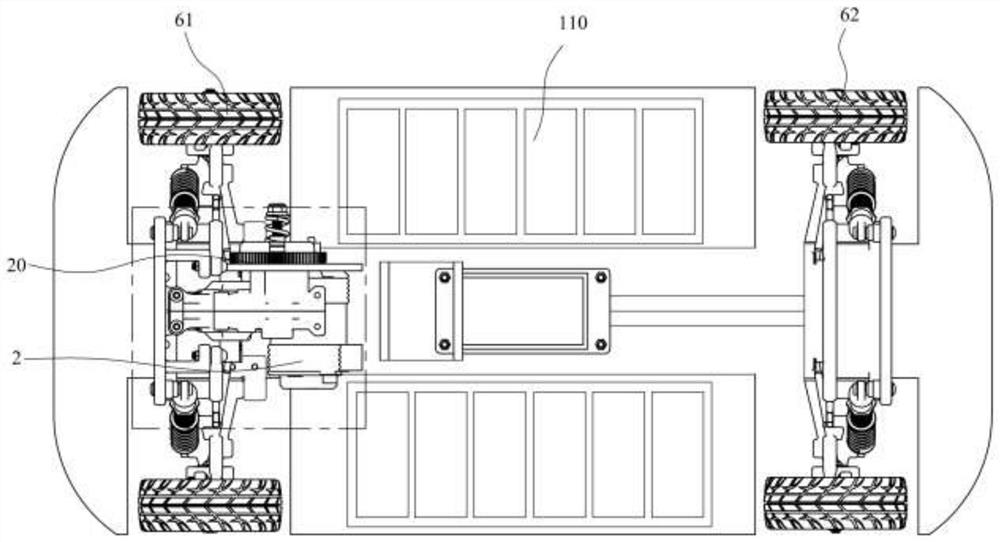

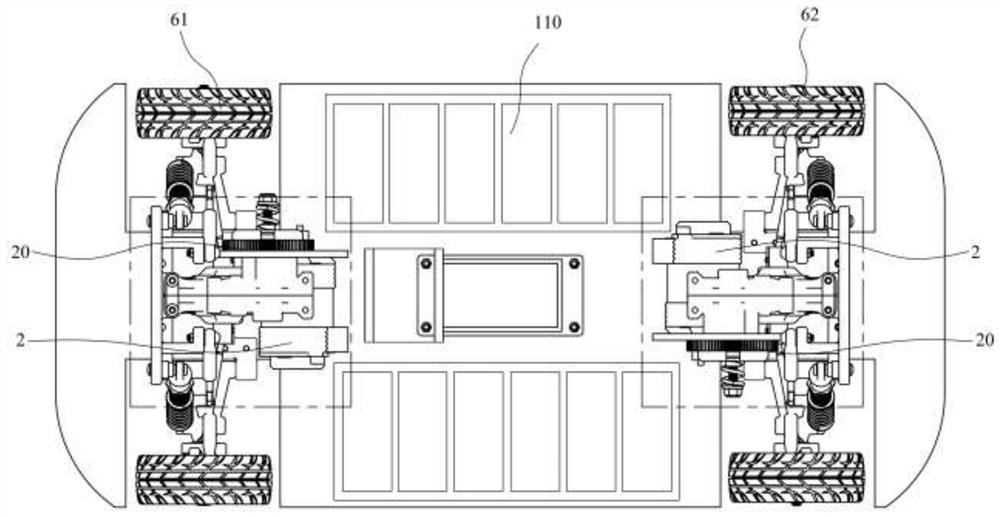

[0114] Such as Image 6 , 7 As shown, an embodiment of a four-wheel drive electric vehicle including the electro-hydraulic hybrid drive system is shown.

[0115] One of the preferred embodiments is a four-wheel drive electric vehicle driven by front and rear axles, such as Image 6 As shown, the four-wheel drive electric vehicle includes a battery pack 110, a first drive axle 35, a second drive axle 36, a differential 31, and a second hydraulic pump / motor 40, and the electro-hydraulic hybrid drive system 1 is set at On the first drive axle 35, and through the differential 31, it is connected with the left half shaft 32 and the right half shaft 33 of the first drive axle 35 to drive the first wheel 61 to move, and the second hydraulic pump / motor 40 passes through the differential 31 is connected with the left half shaft 32 and the right half shaft 33 of the second drive axle 36 and drives the second wheel 62 to move, and the second hydraulic pump / motor 40 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com