Test device used for ultrasonic field shear force measurement

An experimental device and shear force technology, applied in the direction of measuring device, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve problems such as inability to deeply understand the mechanism of ultrasonic action, inability to optimize ultrasonic power matching, etc., and achieve good fixation effect , Simple structure, optimized power matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

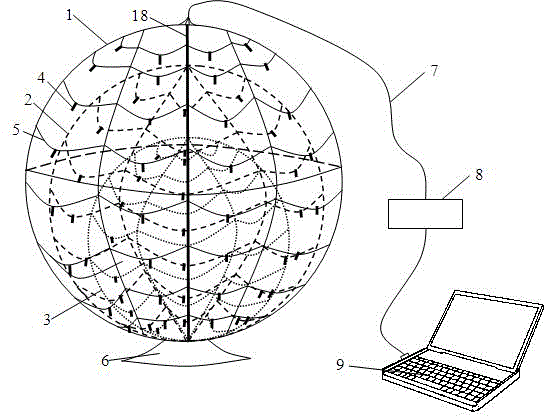

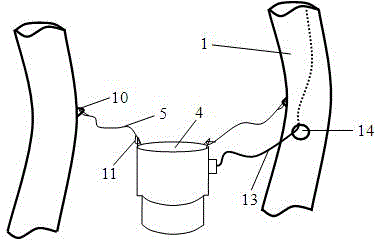

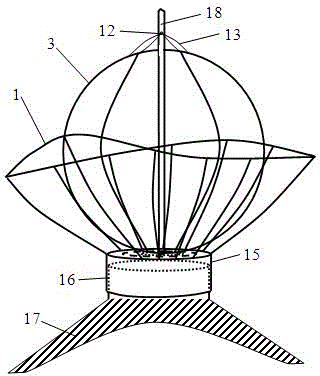

[0025] see figure 1 , is a schematic diagram of the overall structure of an experimental device for ultrasonic field shear force measurement according to the present invention. A three-level spherical sensor array body structure composed of frame 3. The diameters of the first, second and third spherical steel frames 1, 2, and 3 are sequentially set together in order from large to small. The second spherical steel frames 2 are set on the inner bottom of the first spherical steel frame 1, and the third The first-level spherical steel frame 3 is set on the inner bottom of the second-level spherical steel frame 2. During the suit, the third-level spherical steel frame is closely attached to the center bottom of the vertical center line. The diameter of the three-stage spherical steel frame can be reasonably determined according to the size of the reaction vessel. For example, for a container with a length and width of 50 cm, the diameters of the first, second, and third-stage sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com