Maintenance alert system for heavy-duty trucks

a maintenance alert and heavy-duty technology, applied in the direction of machines/engines, electrical control, instruments, etc., can solve the problem of unfavorable time-consuming and laborious tilting of the hood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

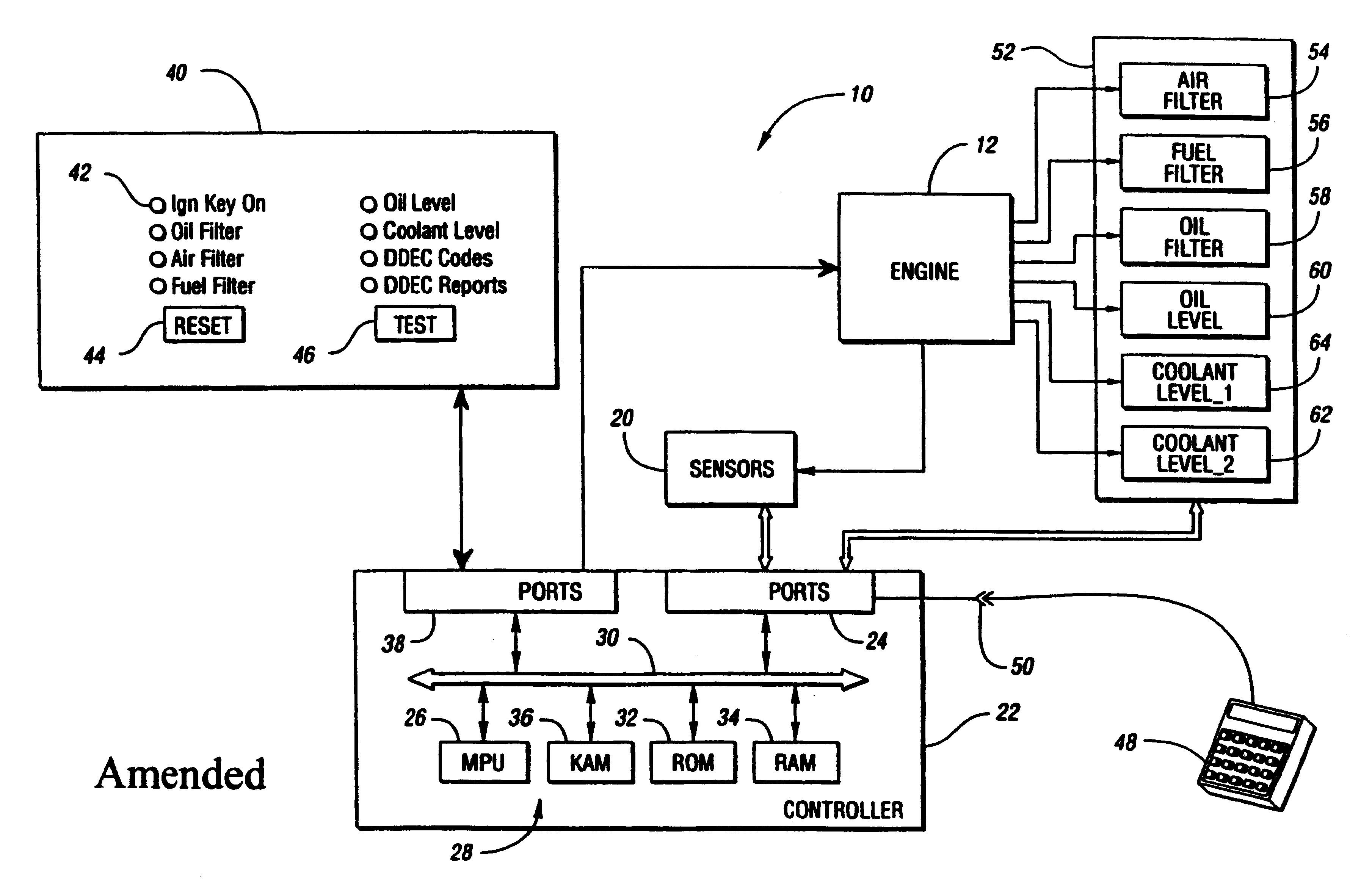

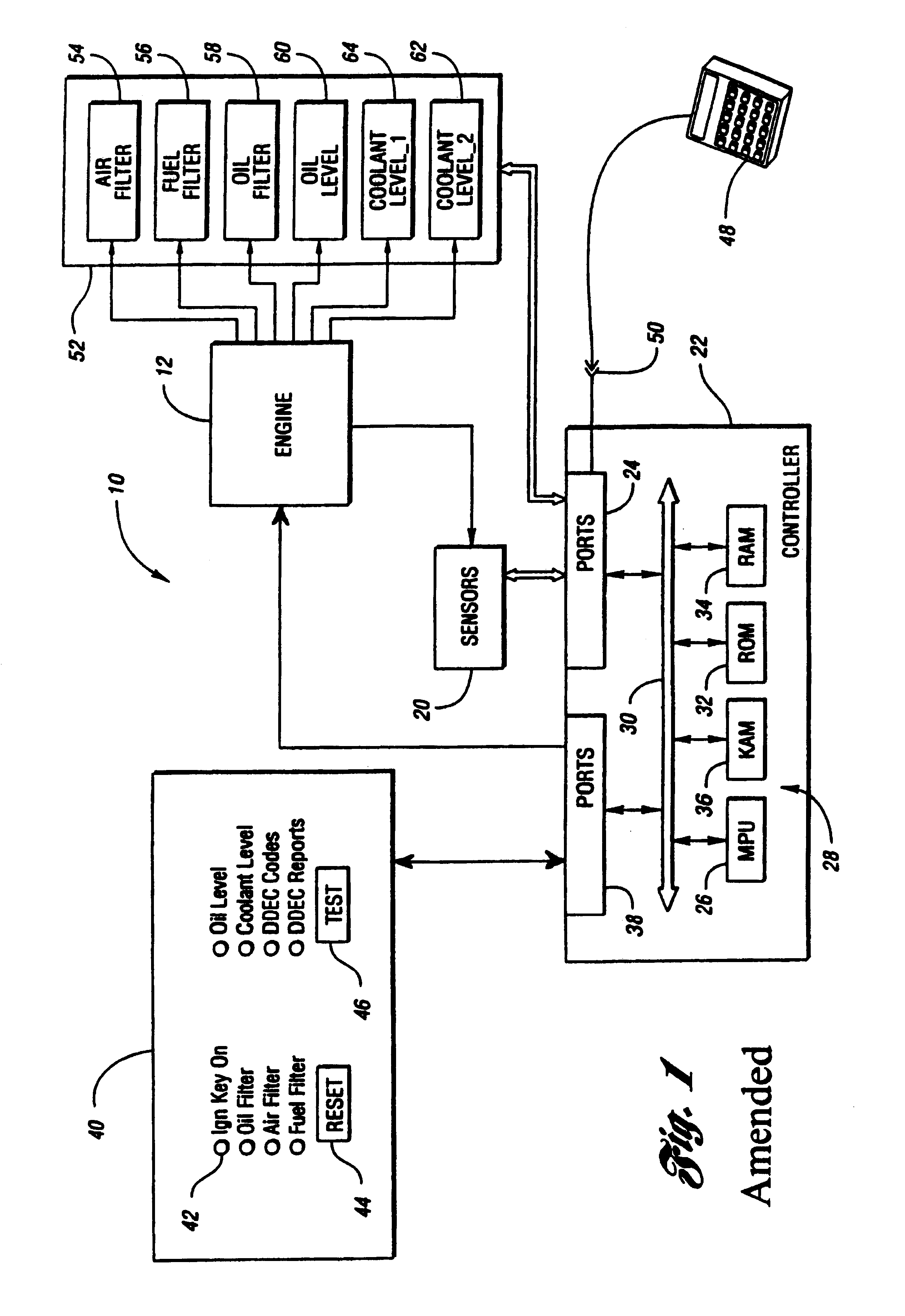

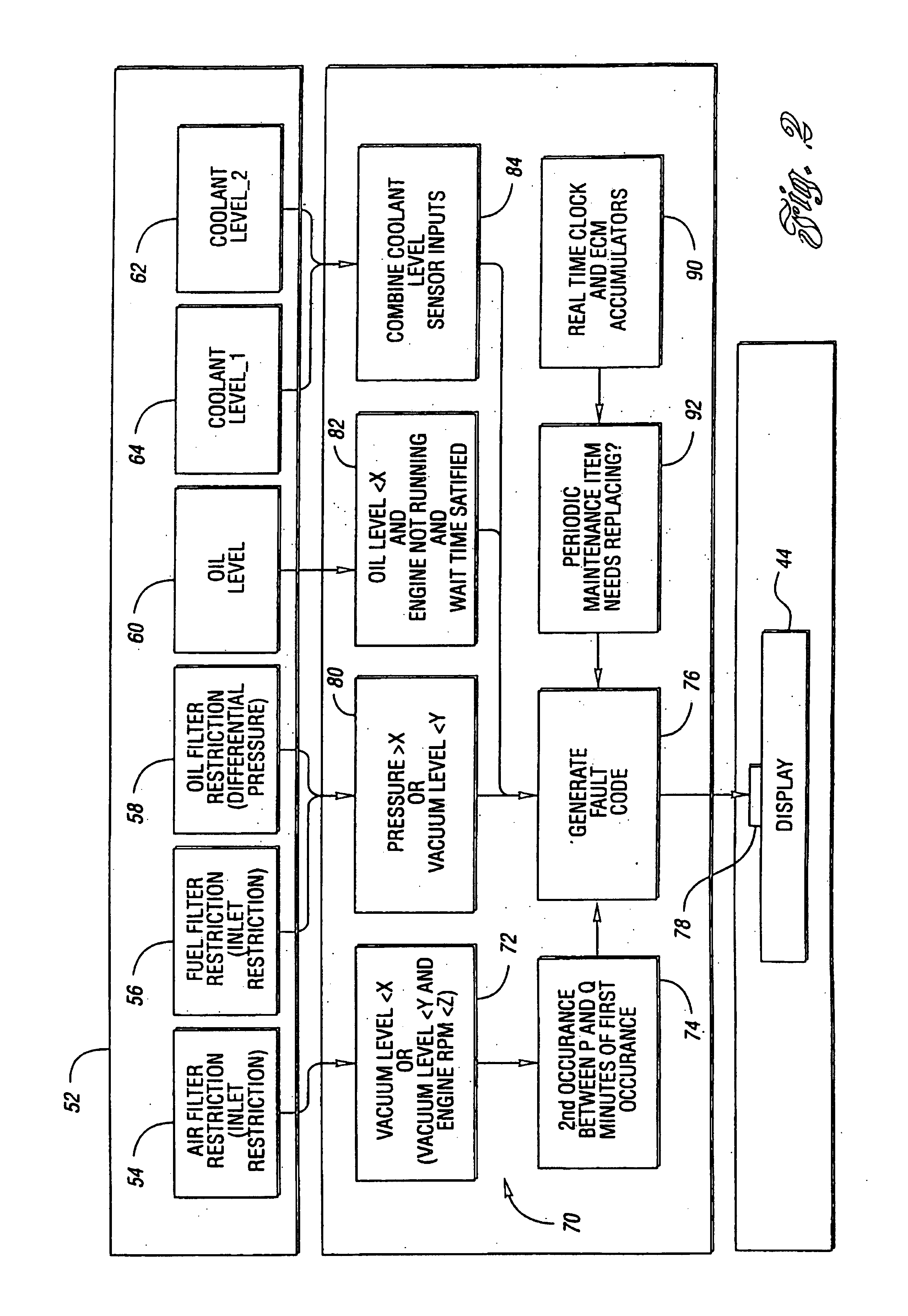

[0018]Referring to FIG. 1, a system for controlling a heavy duty truck is shown. The system, generally indicated by reference numeral 10, includes an engine 12 having a plurality of cylinders, fed by fuel injectors. In a preferred embodiment, engine 12 is a compression-ignition internal combustion engine, such as a four, six, eight, twelve, sixteen or twenty-four cylinder diesel engine, or a diesel engine having any other desired number of cylinders. The fuel injectors are receiving pressurized fuel from a supply connected to one or more high or low pressure pumps (not shown) as is well known in the art. Alternatively, embodiments of the present invention may employ a plurality of unit pumps (not shown), with each pump supplying fuel to one of the injectors.

[0019]The system 10 may also include various sensors 20 for generating signals indicative of corresponding operational conditions or parameters of engine 12, the vehicle transmission (not shown), and other vehicular components. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com