Novel rotating miller

A rotary milling machine, a new type of technology, applied in milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of high processing cost, increased workload, slow turning speed, etc., to achieve convenient installation and positioning, avoid potential safety hazards, guarantee The effect of parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

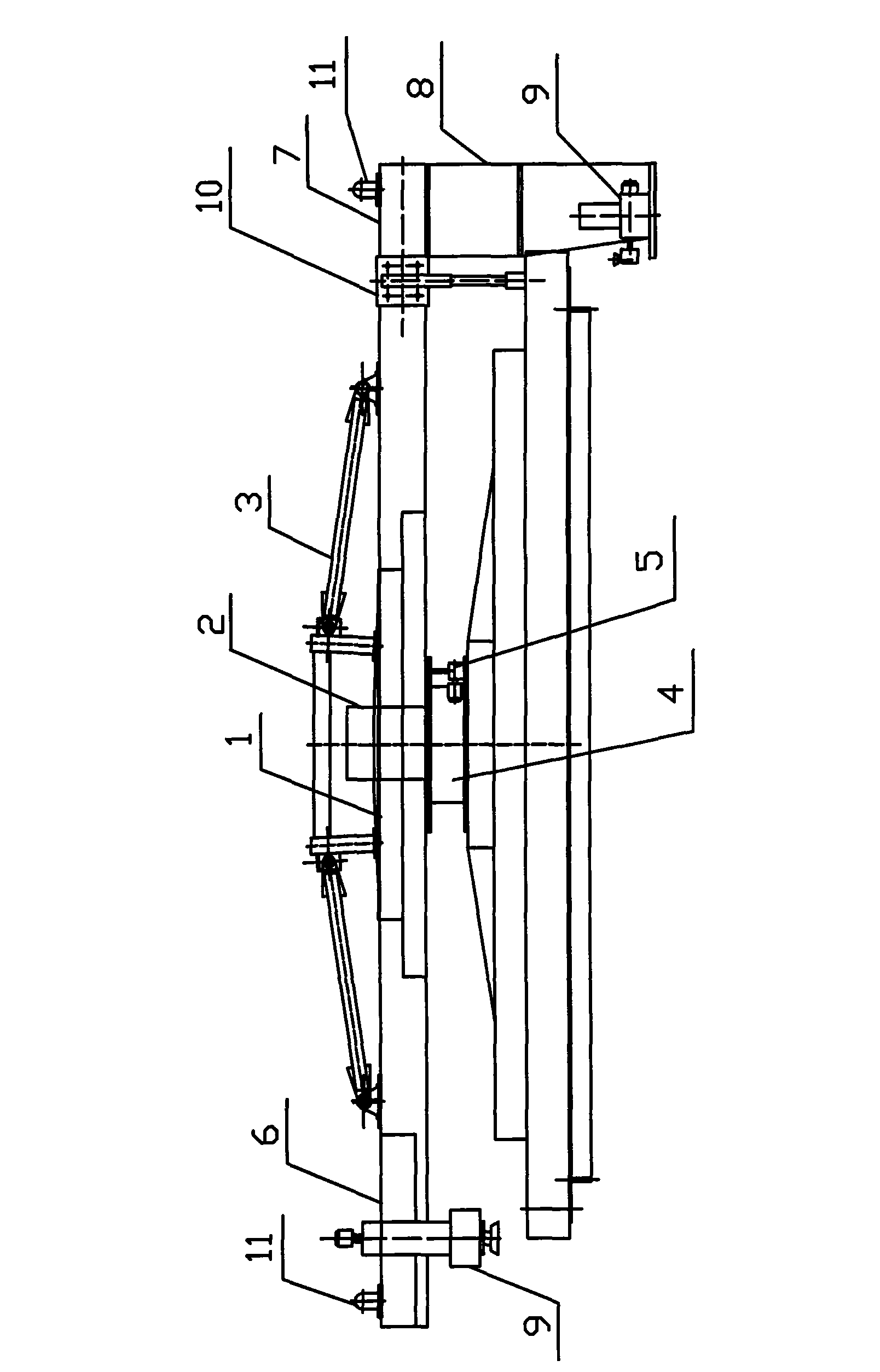

[0022] Such as figure 1 It shows an embodiment of the present invention, a rotary milling machine, including a main beam 1, the main beam 1 is connected with an electrical cabinet 2 provided, a tie rod mechanism 3 is arranged above the main beam 1, and a A workbench 4 is provided below, and a rotary mechanism 5 is provided on the side of the lower end of the workbench 4. The left and right ends of the main beam 1 are provided with a left beam 6 and a right beam 7, and the right beam 7 is connected with a longitudinal beam 8 arranged vertically. , the left beam 6 is connected with a power cutting head 9, the right beam 7 is also connected with a power cutting head 9 through the longitudinal beam 8, and a support structure 10 is provided on the side of the junction between the main beam 1 and the right beam 7, and the support structure 10 is rigid The wheel can adjust the deflection of the main beam 1 up and down. There are warning lights 11 on the left beam 6 and the right beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com