Turning-over device and method for tooth ring of rotation bearing

A slewing bearing and ring gear technology, which is applied to the field of slewing bearing ring gear turning devices, can solve the problems that the ring gear cannot be turned over many times, the efficiency of changing the length of turning, and the inability to follow the workpiece, so as to shorten the loading and unloading time and improve the utilization rate. , The effect of maintaining machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

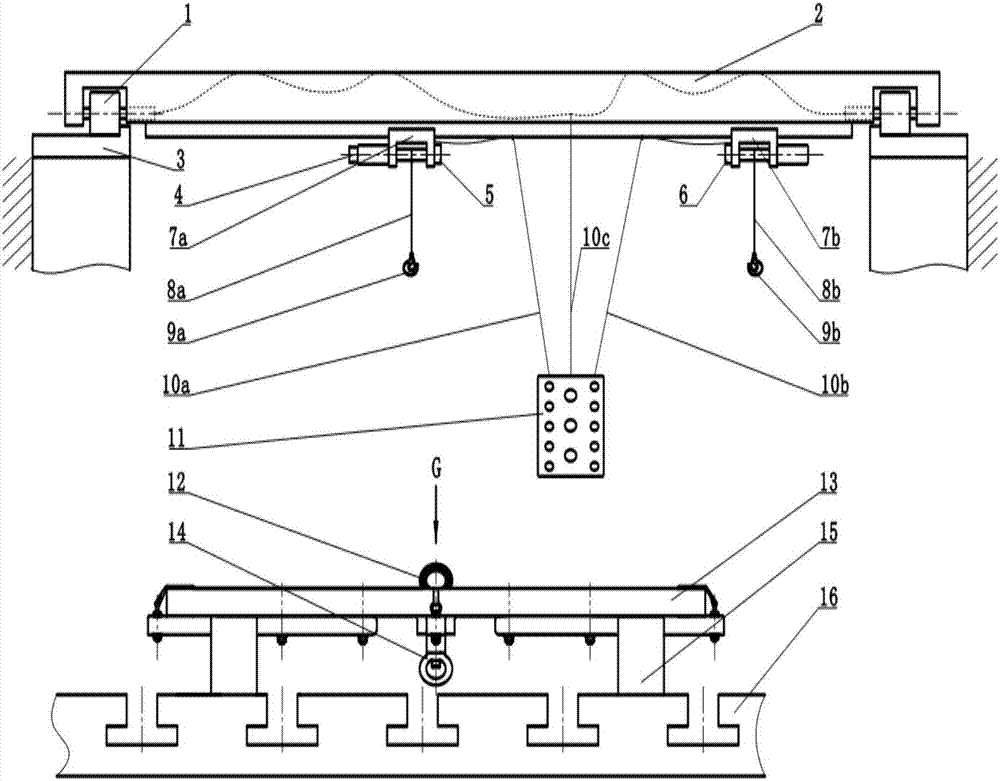

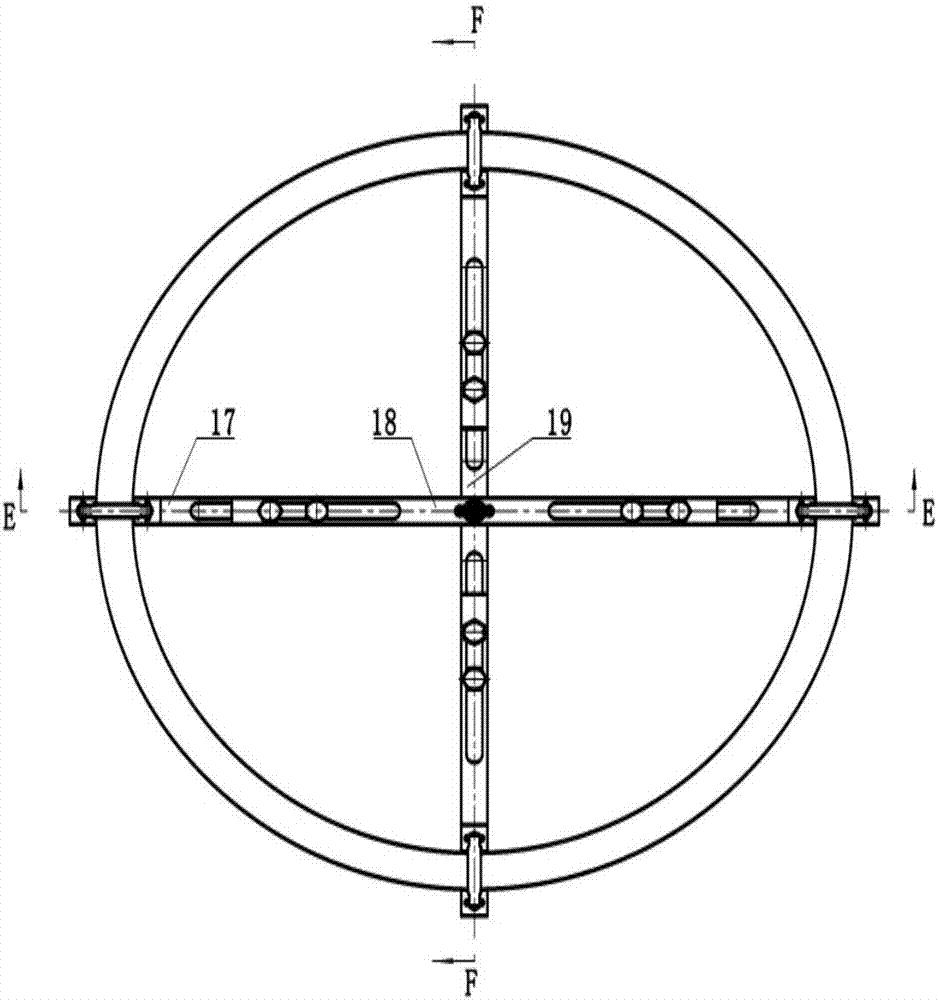

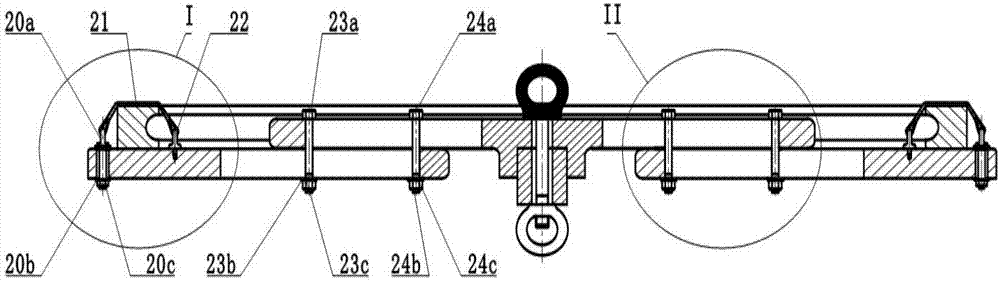

[0037] The invention provides a turn-over device for a slewing bearing ring gear, which includes a lifting system, a control system, a work clamp system and a protection system.

[0038] The lifting system includes a roller 1, a crossbeam 2, a guide rail 3, a first elevator 7a and a second elevator 7b; the roller 1 is placed on the guide rail 3, the crossbeam 2 is installed on the roller 1, the The roller 1 can move longitudinally on the guide rail 3, the first elevator 7a and the second elevator 7b are installed on the beam 2, and the first elevator 7a and the second elevator 7b can move on the The crossbeam 2 is moved laterally, the drums of the first elevator 7a and the second elevator 7b are respectively wound with a first sling 8a and a second sling 8b, and the first sling 8a and the first sling The lower ends of the two slings 8b are equipped with a first hook 9a and a second hook 9b respectively.

[0039] The rollers 1 and the guide rails 3 each have two pieces symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com