Ship hull sectional turn-over method and special-purpose rolling rack

A rolling rack and hull technology, which is applied to ship components, ship construction, ships, etc., can solve the problems of small division, segmental or segmental local structure wrinkles, poor safety, etc., to speed up turning over and ensure closing The effect of good quality and stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

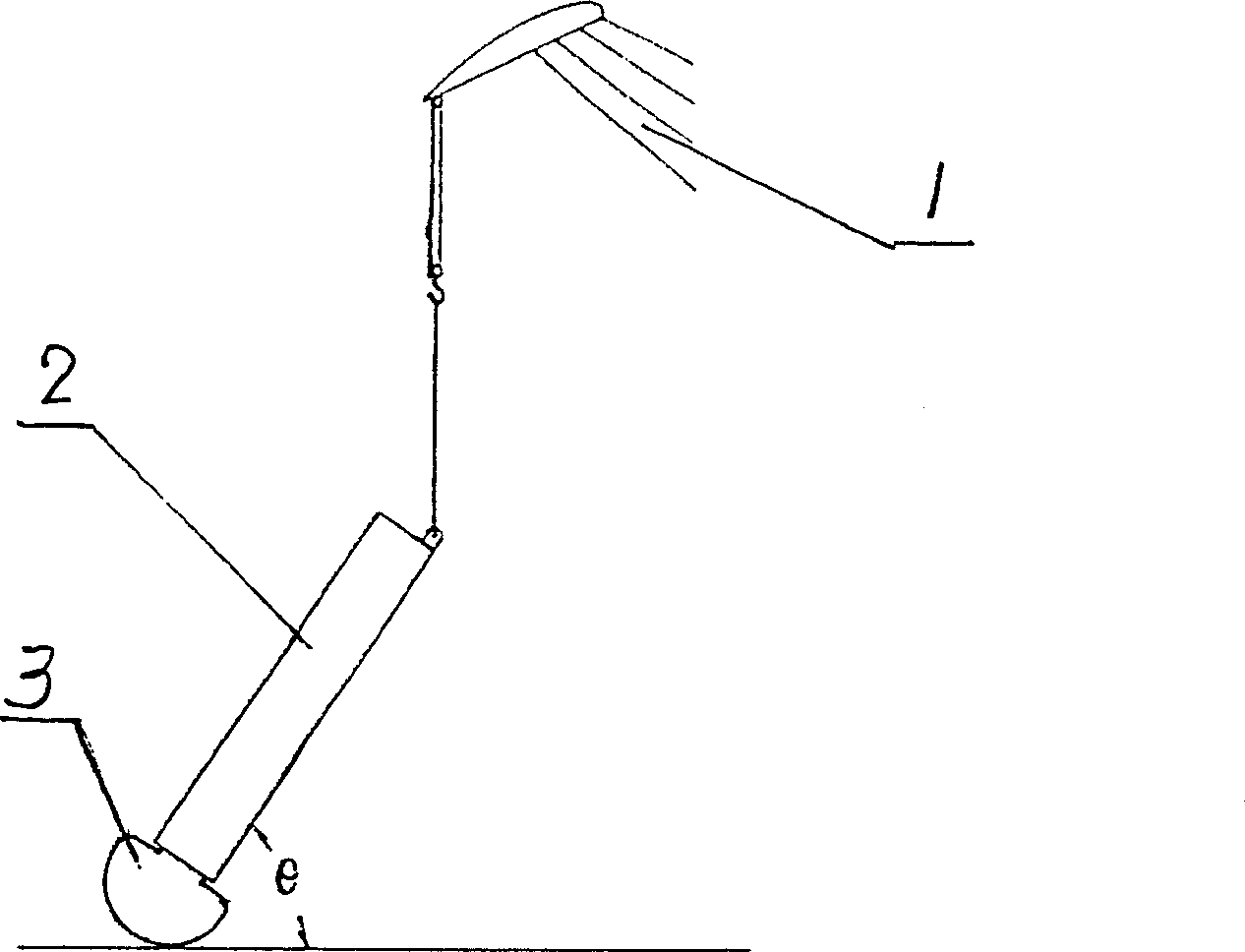

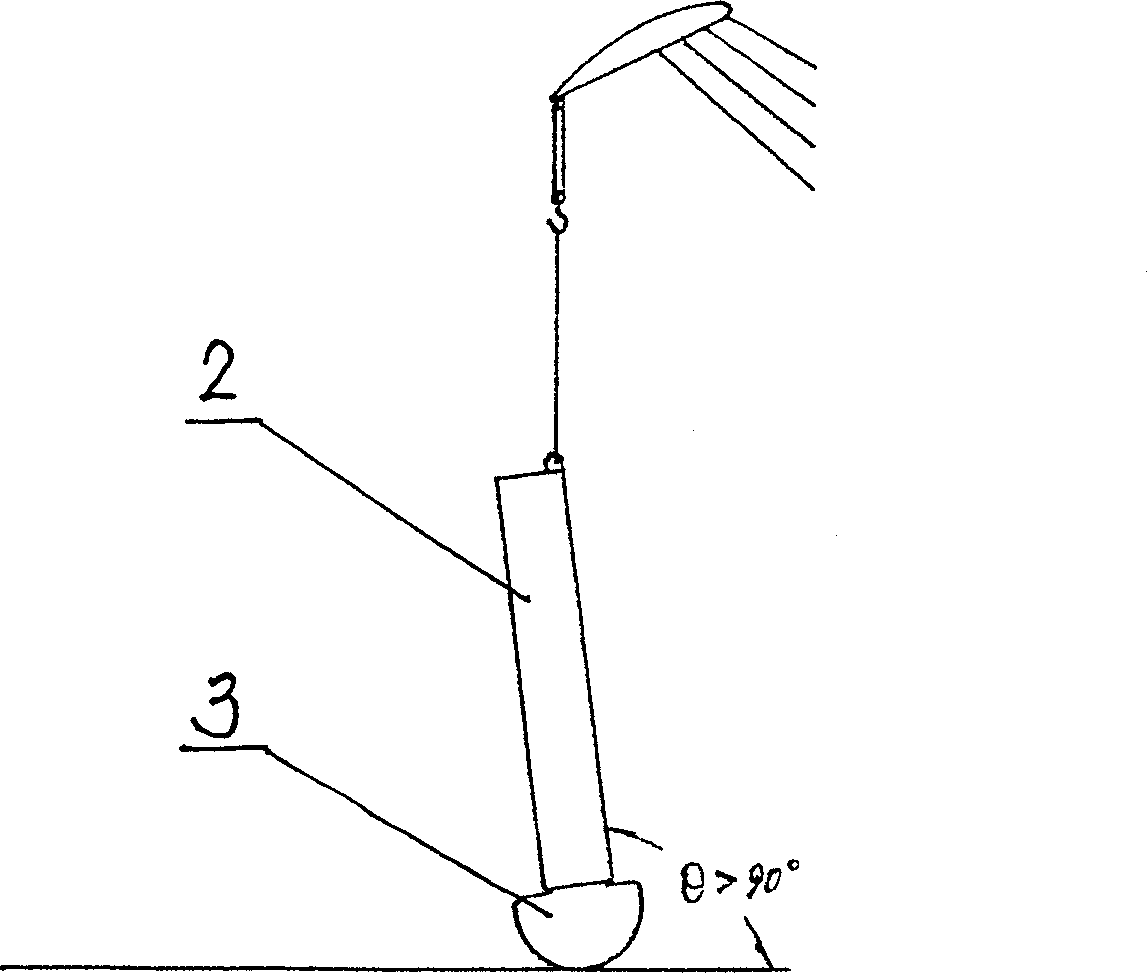

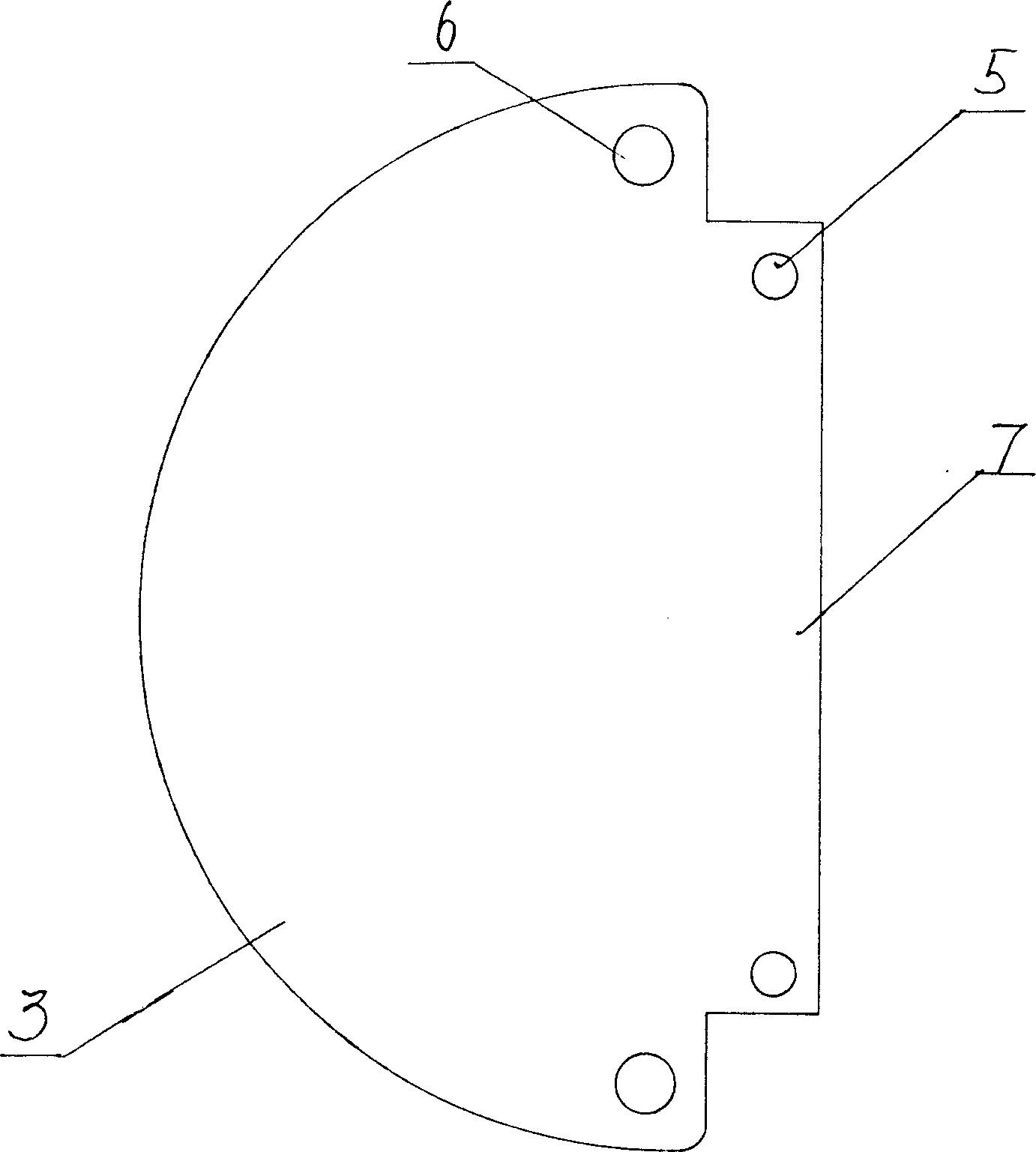

[0021] In the segmental turnover method of the hull of the present invention, at first two sides at one end of the segment (2) are respectively fixed with a 180° arc-shaped (3) rolling rack, and the axis of the arc-shaped rolling rack is turned over in the segment. The faces need to be parallel, and the chord where the arc is located is perpendicular to the longitudinal axis of the segment; then use the crane (1) to lift the other end of the segment, such as figure 1 As shown, at this time, the roller frame is rolling on the ground supporting the segments; when θ=90°, the crane will extend the boom forward (for the bridge crane, it is to move the trolley in the direction of overturning), so that θ>90°, segments form a sloped state, such as figure 2 shown. At this time, as the cable is loosened by the crane, the section rolls to the other side with the roller frame under the action of gravity until the section is in a horizontal state, and the section turns over and ends.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com