A method for installing super high and super large floating cranes in dock

A floating crane, ultra-large technology, applied in the direction of cranes, etc., can solve the problem of hoisting and carrying herringbone frame, the lifting capacity of the gantry crane cannot meet the requirements of the herringbone frame, the overall hoisting of the main arm frame of the boom bracket, and the construction of no floating crane, etc. problems, to achieve the effect of reducing cost and construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

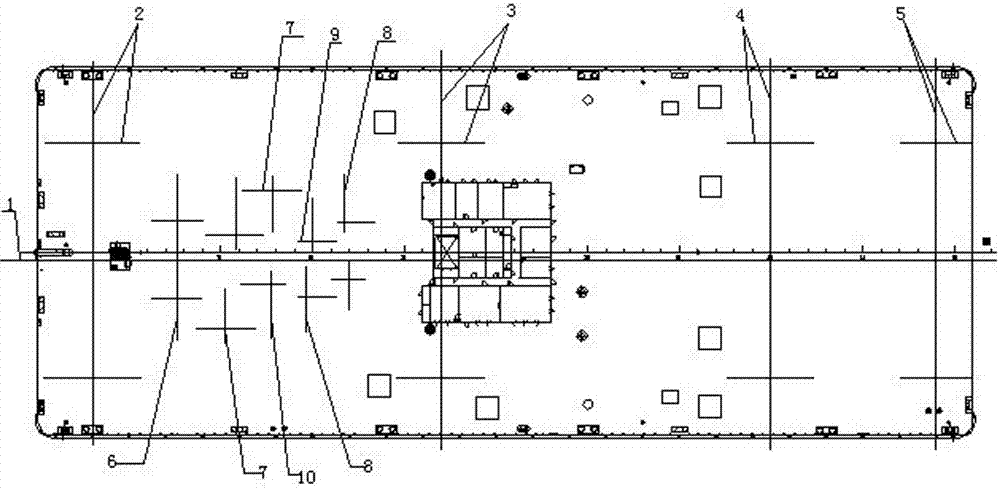

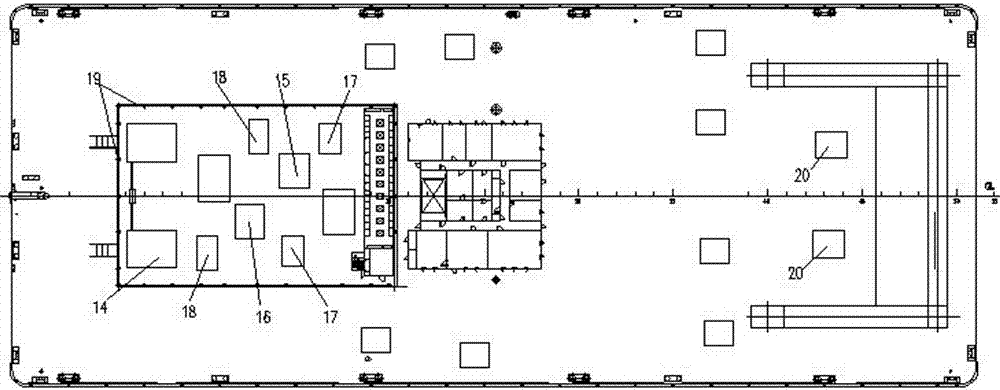

[0032] like Figure 1-8 As shown, a method for installing super high and super large floating cranes in a dock includes the following steps:

[0033] Step 1: After the hull is closed in the dock, adjust the level of the hull, draw the hull deck centerline 1 on the deck surface, and use this as a reference to draw the centerline 2 of the gable frame tie rod and the center line 3 of the gable frame pressure rod , centerline of the rear outrigger of the jib bracket 4, centerline of the front outrigger of the jib bracket 5 and centerline of the luffing mechanism 6, centerline of the main hook lifting mechanism 9, centerline of the auxiliary hook lifting mechanism 10, main hook rigging The centerline 8 of the hook mechanism, the centerline 7 of the hook mechanism of the auxiliary hook rigging, recheck after marking;

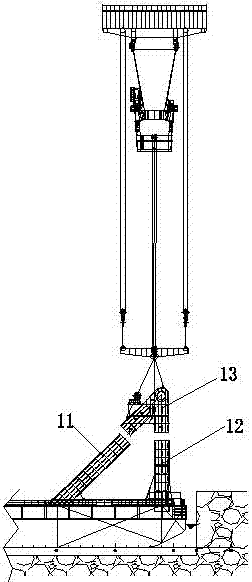

[0034] Step 2: Install and weld the guide plate at the installation position of the jib bracket on the hull deck, use a 900T gantry crane to hoist the rear outrigger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com