Hanger for hoisting equipment

A spreader and hoisting technology, which is applied in the field of equipment hoisting spreaders, can solve problems such as large friction, damage to slings and equipment lugs, and affect hoisting safety, so as to ensure hoisting safety, improve rated hoisting capacity, and reduce construction preparations workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

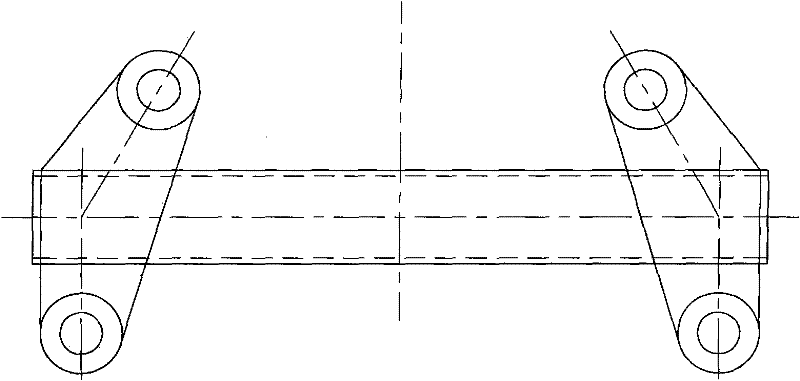

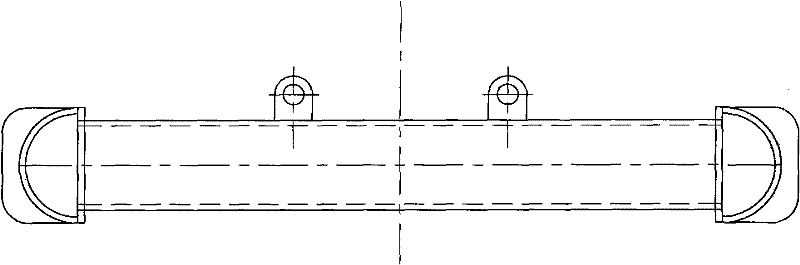

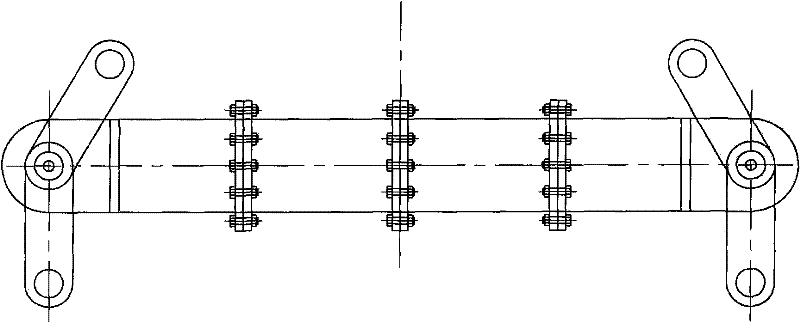

[0032] Such as Figure 5 to Figure 12 As shown, the equipment hoisting equipment includes:

[0033] The beam 1 is a trapezoidal box-shaped structure with a large top and a small bottom, and is assembled and welded by steel plates. Two rows of screw holes 11 are evenly spaced on both ends of the upper surface of the beam 1 .

[0034] The lifting lug 2 includes the lug plate 21. There are four lug plates 21 in this embodiment, which are opposite to each other and symmetrically arranged in the middle of the beam 1. The lug plate 21 is provided with a shaft hole 22. In this embodiment The outside of the lug plate is also provided with a lug reinforcing ring plate 23, and the inside of the lug plate is also provided with a lug reinforcing rib plate 24 to increase the strength of the lug. The lug reinforcement ring plate and rib plate can be set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com