Radial horizontal well orienting device and method for operating same

A technology of an orientation device and an operation method, which is applied in the field of oil drilling and exploitation, can solve the problems of inaccurate orientation, reduced efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

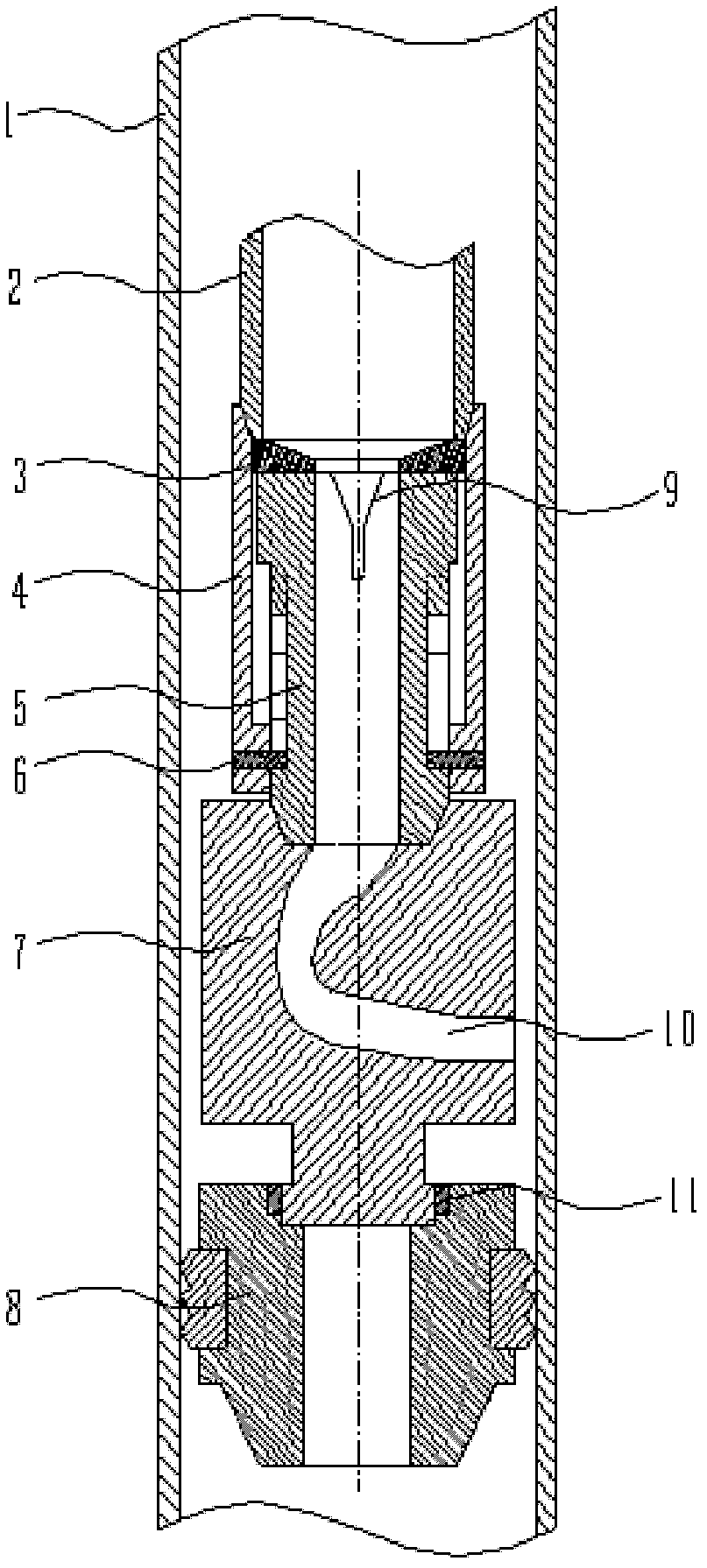

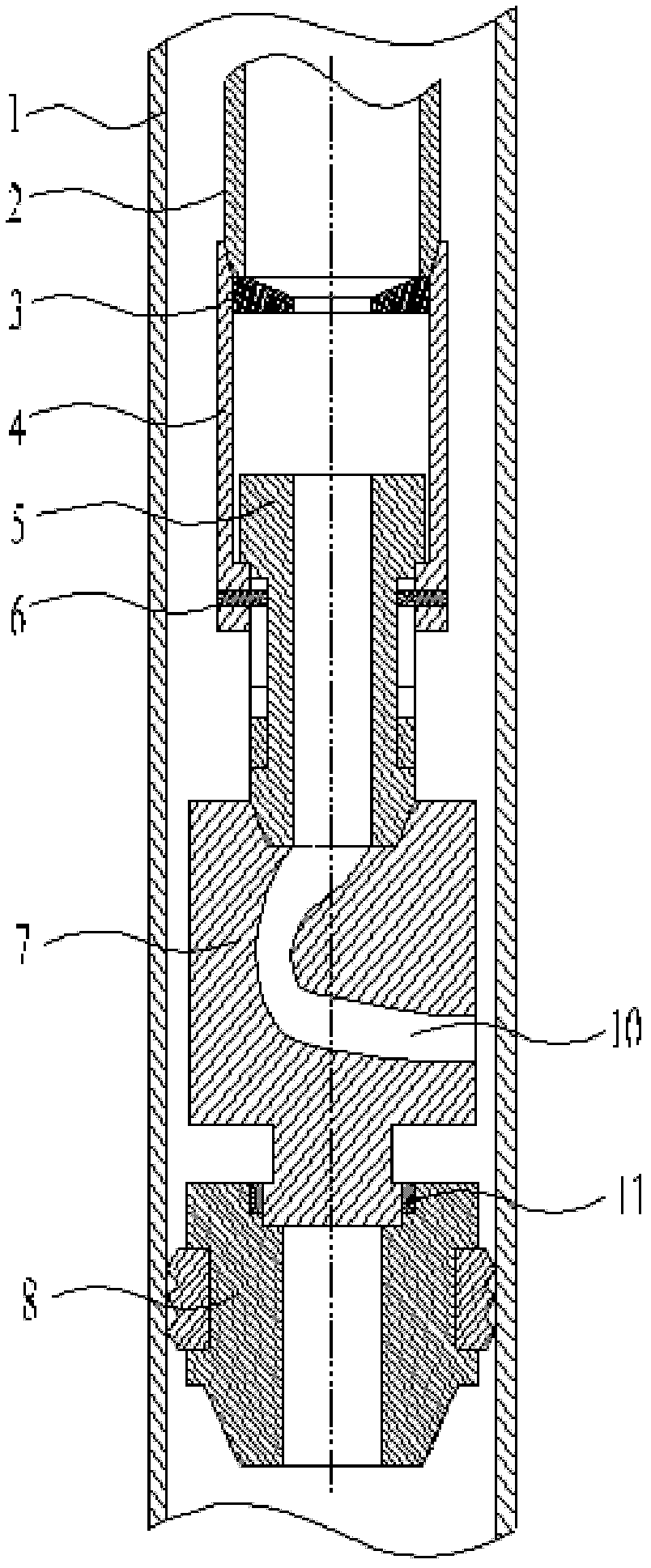

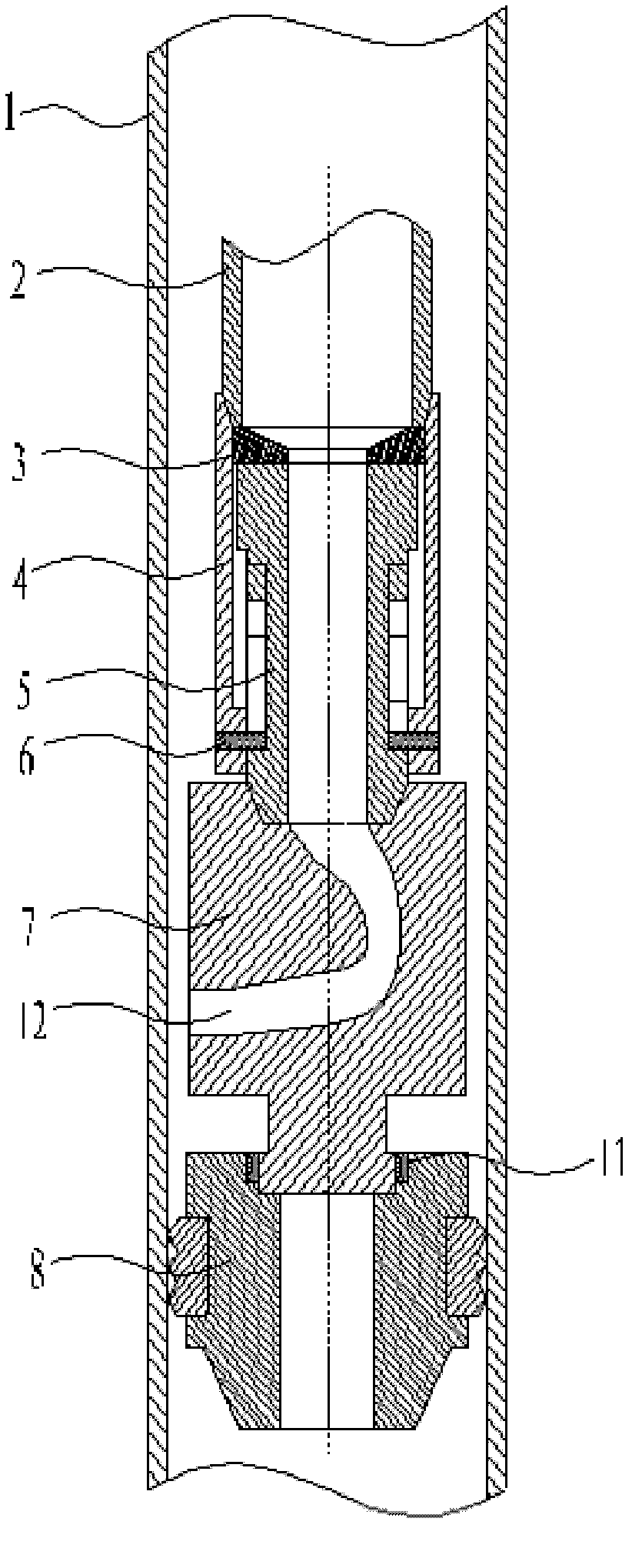

[0026] refer to Figures 1 to 6 Embodiments of the present invention are further described:

[0027] Radial horizontal well directional device:

[0028] The bottom surface of the steering cylinder 4 is provided with a central hole, and the surface of the hole is provided with four radial guide pins 6 evenly distributed. The top end of the steering cylinder 4 is connected to the tubing column 2 with a screw thread, and the upper end of the cylinder is inlaid with a guide sleeve 3. The inside of the cylinder is connected to a stepped cylindrical steering rod 5 with a central hole. The chute, the bottom end of the reduced-diameter column passes through the center hole of the steering cylinder 4 to connect the diverter 7. The steering gear 7 is provided with a steering curve 10 connected to the central hole of the steering rod 5 , and the bottom end of the steering gear 7 is connected to the oil pipe anchor 8 through a bearing 11 .

[0029] The operating steps of the radial hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com