Rotary angle-wrapping forming stamping die

A stamping die and angle wrapping technology, which is applied in the field of structural improvement of stamping dies, can solve problems such as low production efficiency, complex structure, and difficult control, and achieve the effects of reducing maintenance costs, improving production efficiency, and shortening the molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

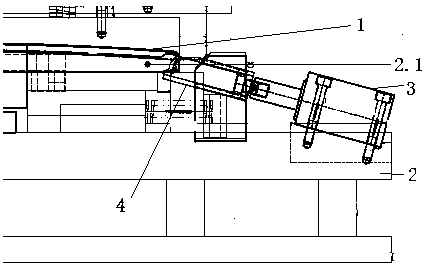

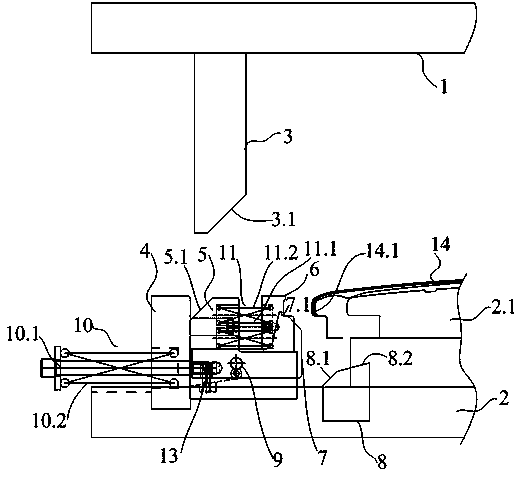

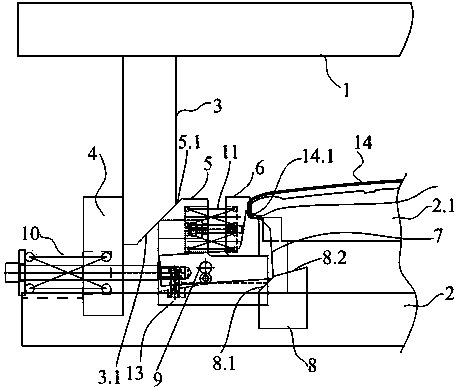

[0023] refer to Figure 2 to Figure 5 , the present embodiment takes the rotary corner forming of the refrigerator door shell 14 as an example. The parts 14.1 are one-to-one corresponding to the angle wrapping forming mechanism. The refrigerator door shell 14 is placed on the lower mold plate 2.1 on the lower mold base 2. The angle wrapping forming mechanism includes a side pusher assembly and a rotating angle wrapping forming assembly. The side push assembly includes a push rod 3, a push rod limit block 4, a slider seat 5, a binder plate 6 and an elastic reset part 10 of the slider seat, one end of the push rod 3 is fixed on the upper mold base 1, and the push rod limit block 4 is fixed on the lower die base 2 to limit the push rod 3 and the slider base 5; the slider base 5 is slidably installed on the lower die base 2, and the binder plate 6 is arranged on the slider base 5 and The block seat 5 is connected as a whole through the elastic part 11. The function of the pressin...

Embodiment 2

[0027] During the molding process, the guiding slope of the top block 8 plays the role of driving the pendulum block 7 to generate rotational movement. In this embodiment, the guiding slope includes two slopes with different inclination angles, which are connected up and down, and the slope angle of the lower slope 8.1 is greater than The inclination angle of the upper slope 8.2, the slope angle of the bottom slope 8.1 is advisable with 30-60 ° (in this embodiment, its slope angle is 45 °), the slope angle of the top slope 8.2 is advisable with 10-20 ° (in this embodiment Among them, the inclination angle is 15°). During the sliding process of the pendulum block 7 along with the slider seat 5, the lower slope 8.1 first comes into contact with, and its inclination angle is relatively large to make the pendulum block 7 quickly turn up and rotate to form an angle, and improve the forming efficiency. When the pendulum block 7 moves to When the lower slope 8.1 connects with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com