Supply and return water temperature difference control system

A technology for supply and return water temperature difference and control system, which is applied in heating and ventilation control system, heating and ventilation safety system, space heating and ventilation control input, etc. It can solve problems such as excessive energy supply and difficulty in meeting comfort requirements, etc. To achieve the effect of increasing the temperature difference between supply and return water and avoiding the temperature difference between supply and return water being too large or too small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

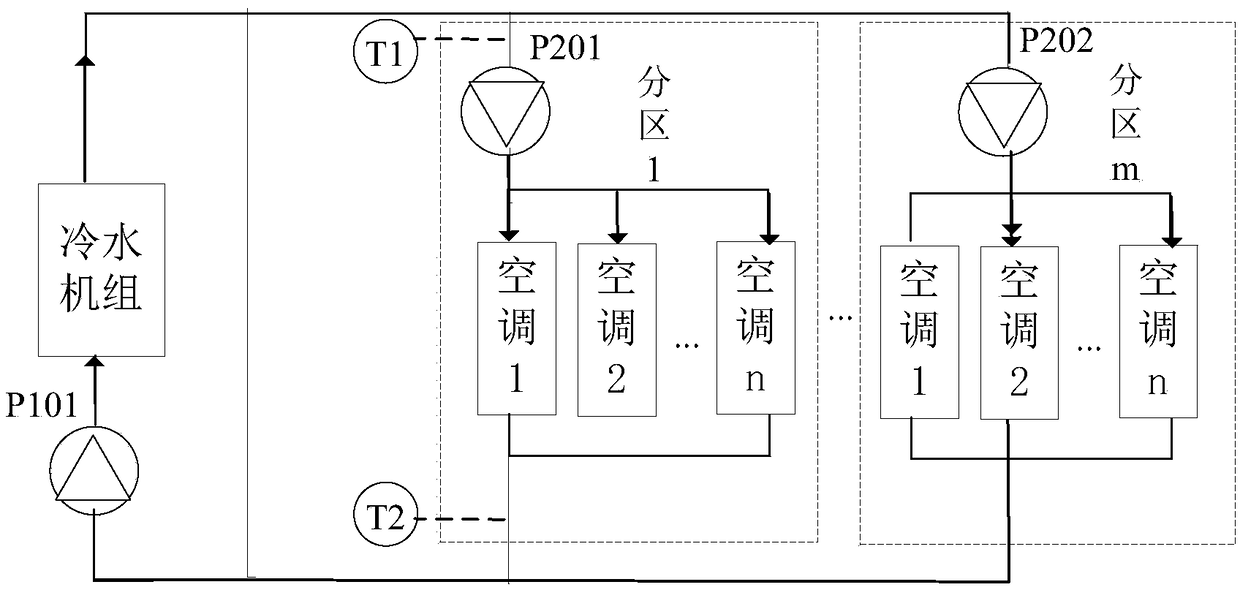

[0019] like figure 1 As shown, this embodiment provides a temperature difference control system for supply and return water, which is applied to large air-conditioning systems. The large air-conditioning system is composed of chillers and distributed in multiple partitions (that is, branch cooling areas, in figure 1 There are m partitions in the system), each partition covers multiple rooms or multiple sub-areas (for example, a larger area in a large shopping mall, factory, etc. includes multiple sub-areas), each room or each sub-area At least one air conditioner is installed inside. In the following description, a room is used as an example for illustration. According to different actual application scenarios, sub-areas may also be used instead of the room in this embodiment. The cold water unit is used to output cold water to each air conditioner, and the water output of the chiller unit is controlled by the total frequency conversion pump P101, and then the cooling capacit...

Embodiment 2

[0052] This embodiment provides a temperature difference control system for supply and return water. In this embodiment, the same parts as in Embodiment 1 are assigned the same reference numerals and their descriptions are omitted.

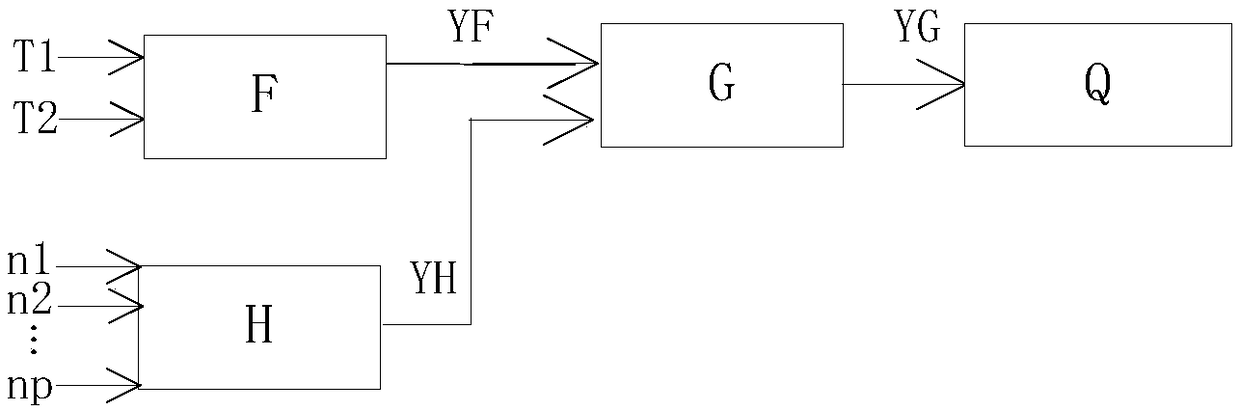

[0053] like figure 2 As shown, in this embodiment, the supply and return water temperature difference control system includes: multiple temperature control systems (not shown), gain characteristic average calculator H, temperature difference controller F, gain controller G, and water supply frequency converter Q .

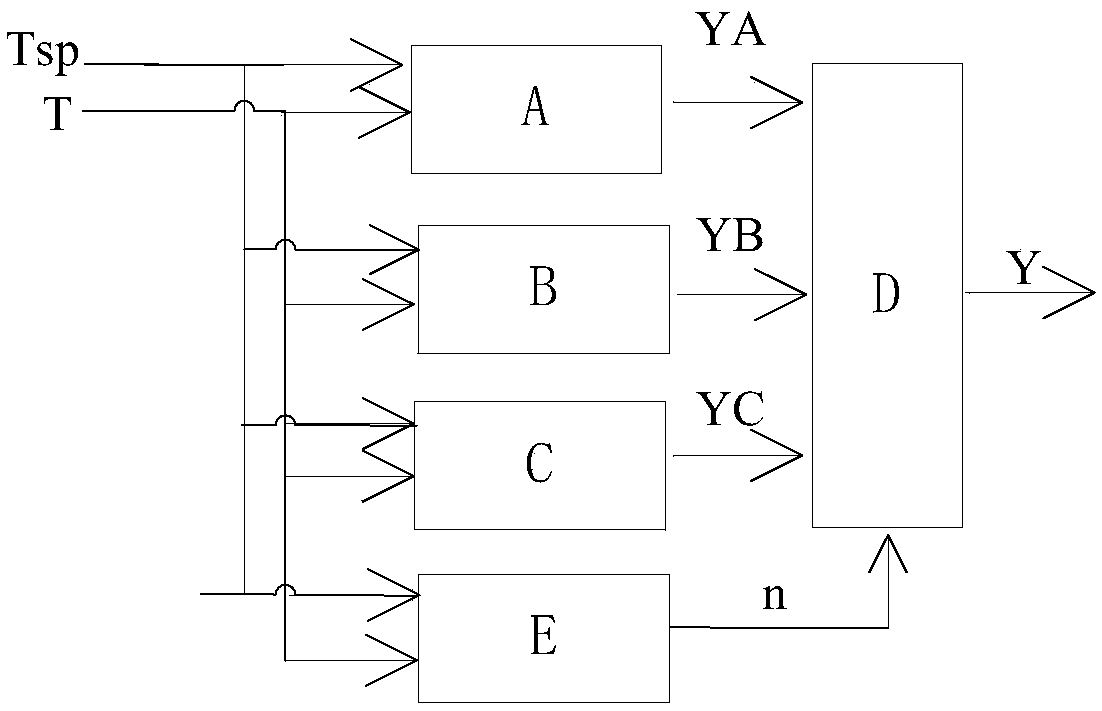

[0054] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the temperature control system in this embodiment includes: a gain self-tuner E, a gain calculator O, and a temperature controller P.

[0055] Regarding the above gain self-tuner E, the actual room temperature T and the preset room temperature Tsp are respectively used as the input of the gain self-tuner E, and the gain characteristic val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com