Power generation system driven by heat pump

a technology of power generation system and heat pump, which is applied in the direction of machines/engines, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of increasing the cost of fossilized fuel purchase, the efficiency of stirling heat engine to be less than the heat efficiency of carnot heat engine by 50%, and the cost of mining fossilized fuel. , to achieve the effect of reducing the requirements of fossilized fuel, preventing the generation of green house gases, and effective raising of heat engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

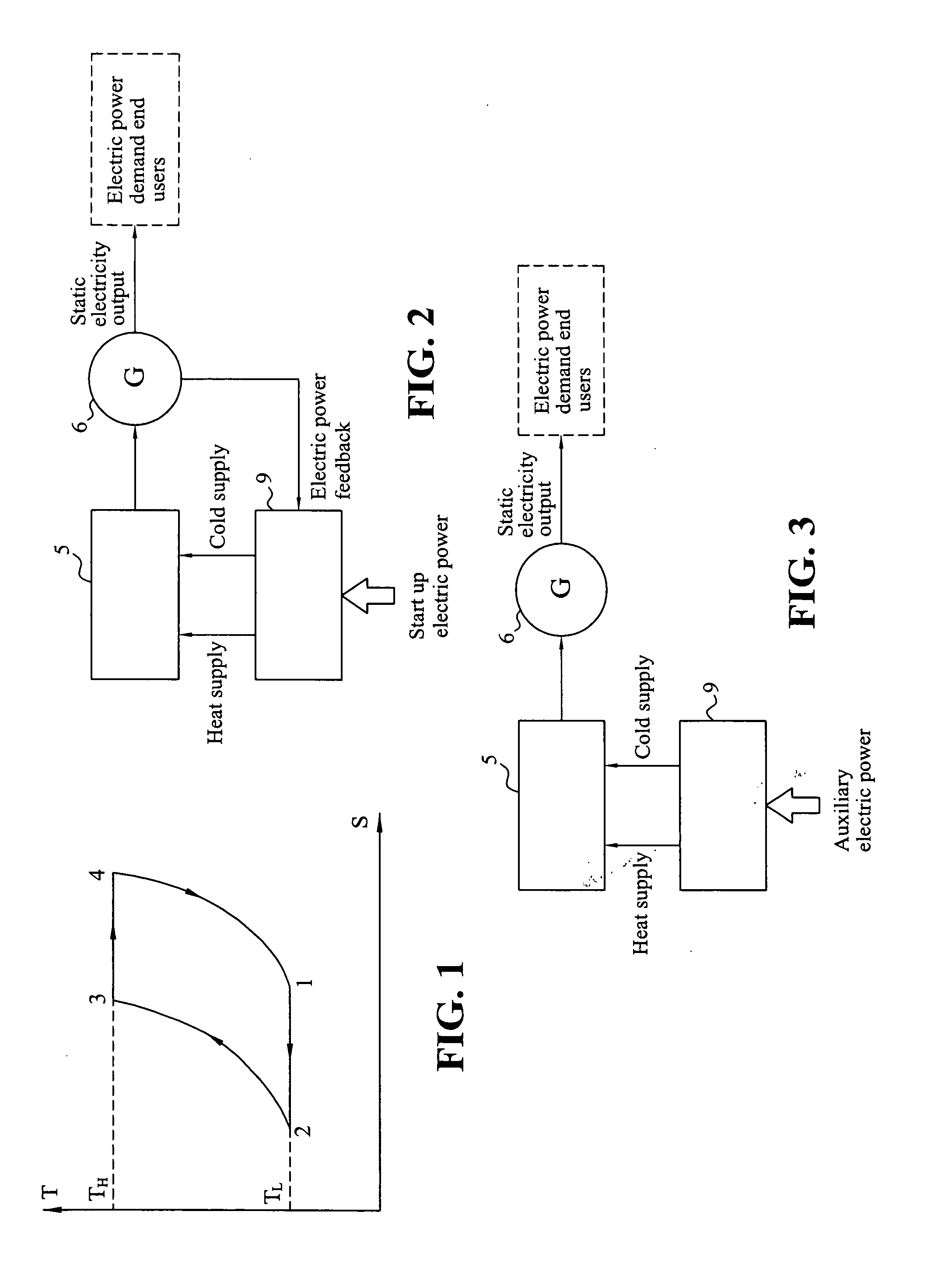

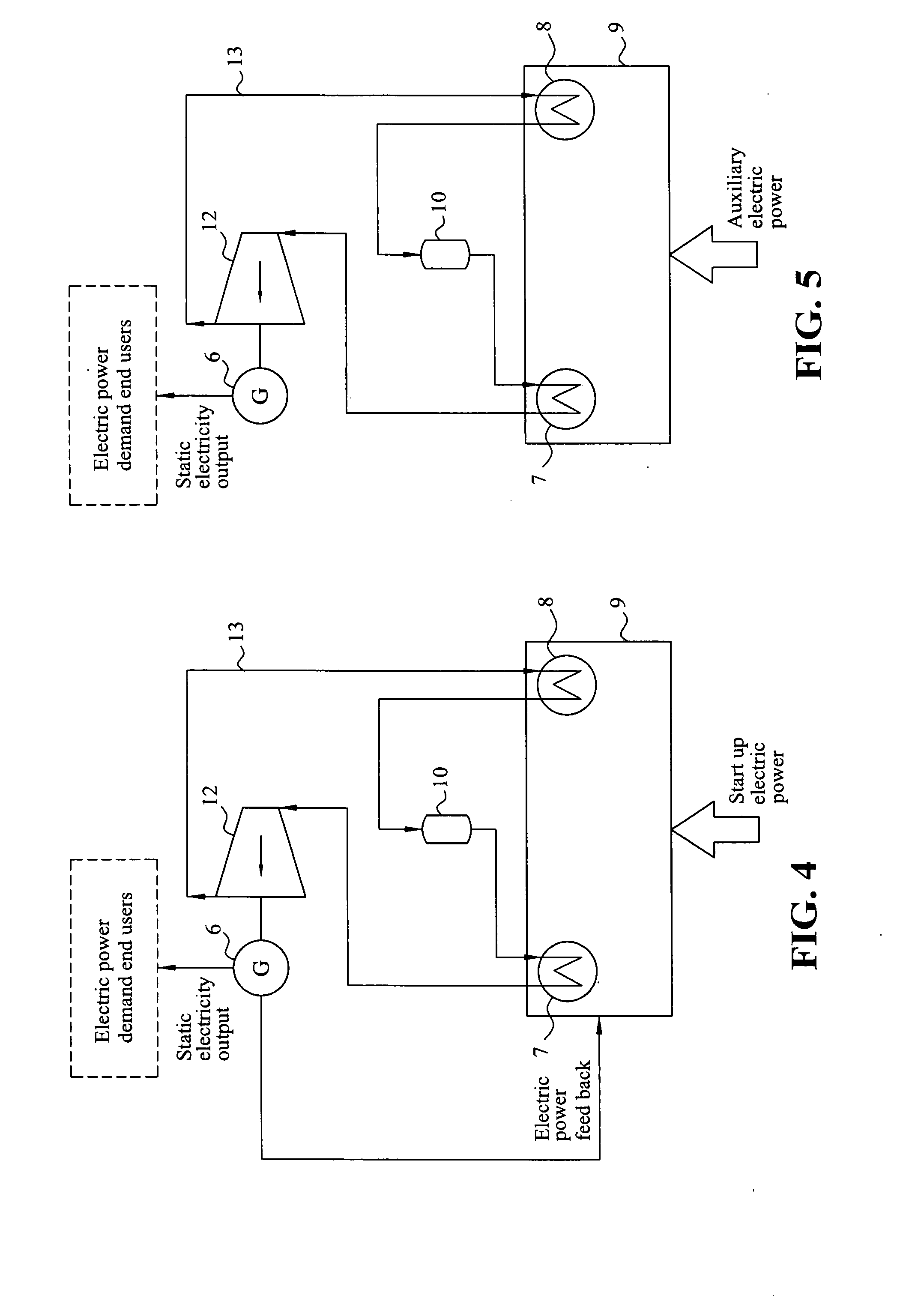

[0001]The present invention relates to a type of power generation system, especially to a power generation system which utilizes heat pump driven heat engine so as to generate electrical energy, in which heat engine could be Stirling's engine or steam turbine.

BACKGROUND OF THE INVENTION

[0002]Introduction of Stirling Cycle:

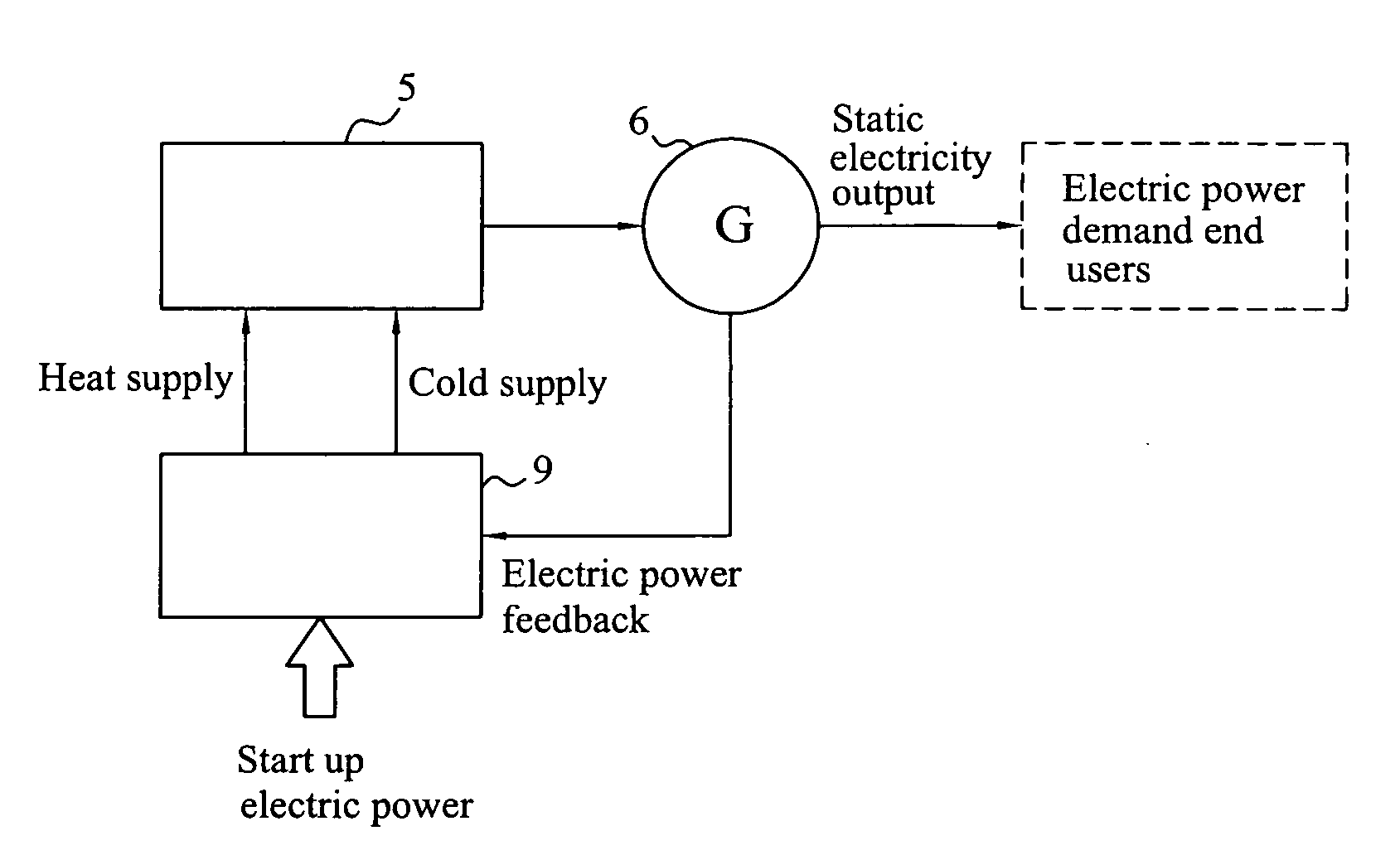

[0003]Stirling Cycle is the process of isothermal heat transfer and isochoric expansion and compression, an ideal Stirling cycle possesses similar heat efficiency as that of Carnot cycle, FIG. 1 is the curve showing the relationship between temperature and entropy of Stirling cycle, in which T is Temperature, S is Entropy, 1˜4 are four work state points, which is described one by one below.

[0004]1-2 Isothermal Compression Process (Heat Quantity is Transferred from Working Fluid to Cold Source):

[0005]The displacement piston, after pushing the working fluid into the cold source, retains in the top dead center position, and the working fluid is cooled down and preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com