High-flow high-speed jet plugging grouting technique under high-pressure water head of hydropower station

A high-speed jet and high-flow technology, applied in water conservancy projects, drilling with liquid/gas jets, sea area engineering, etc., can solve problems such as incomplete completion and rapid expansion of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

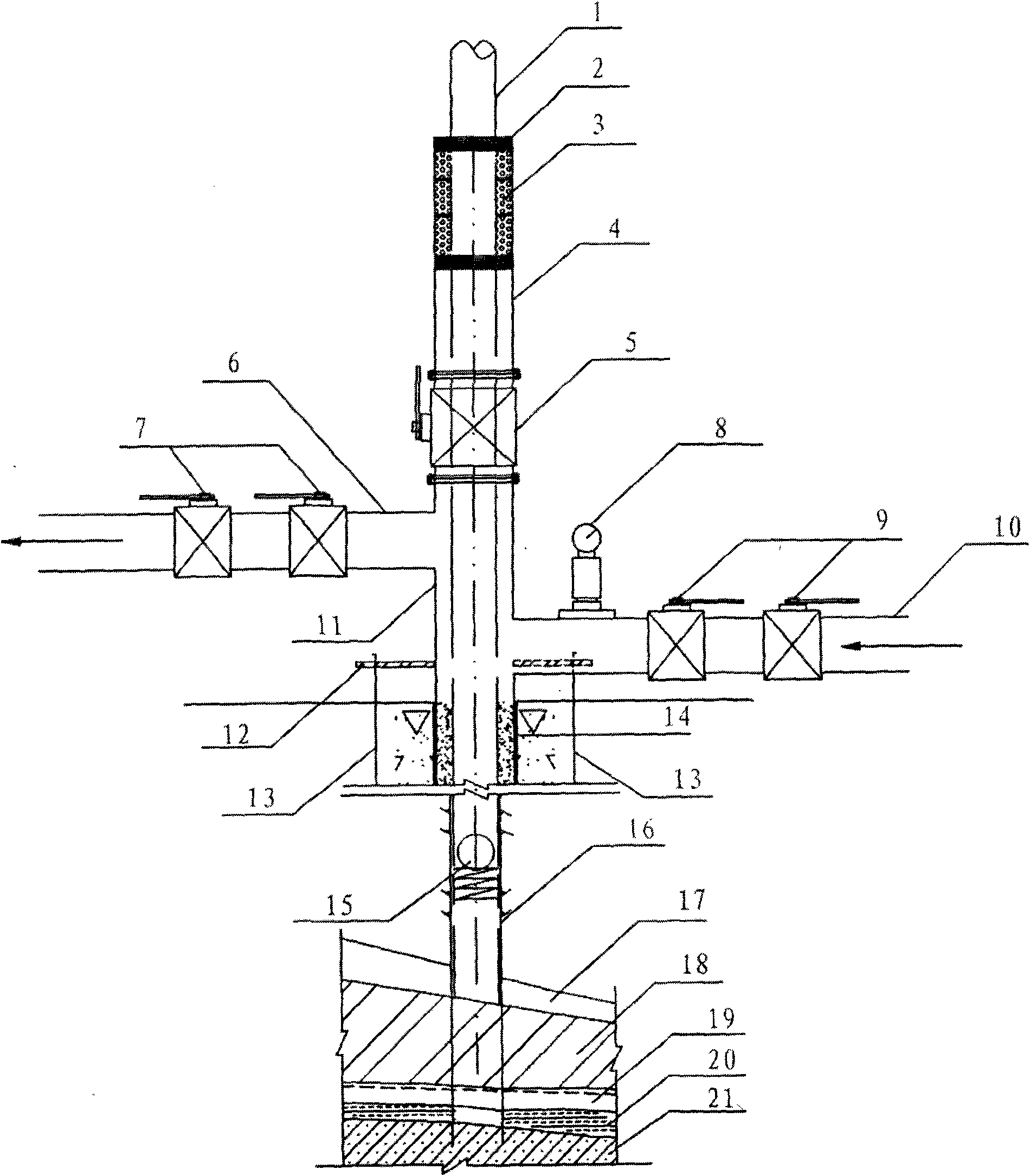

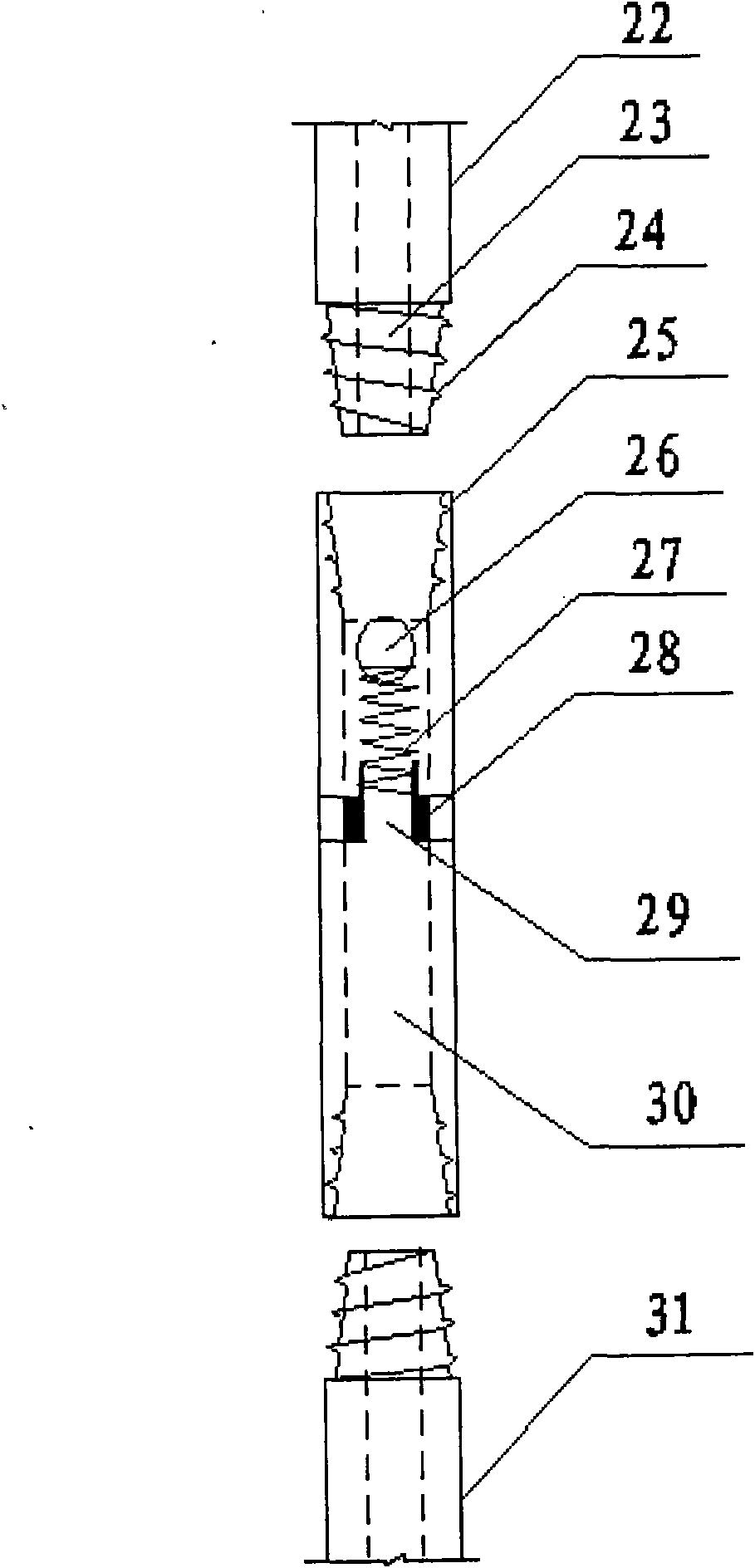

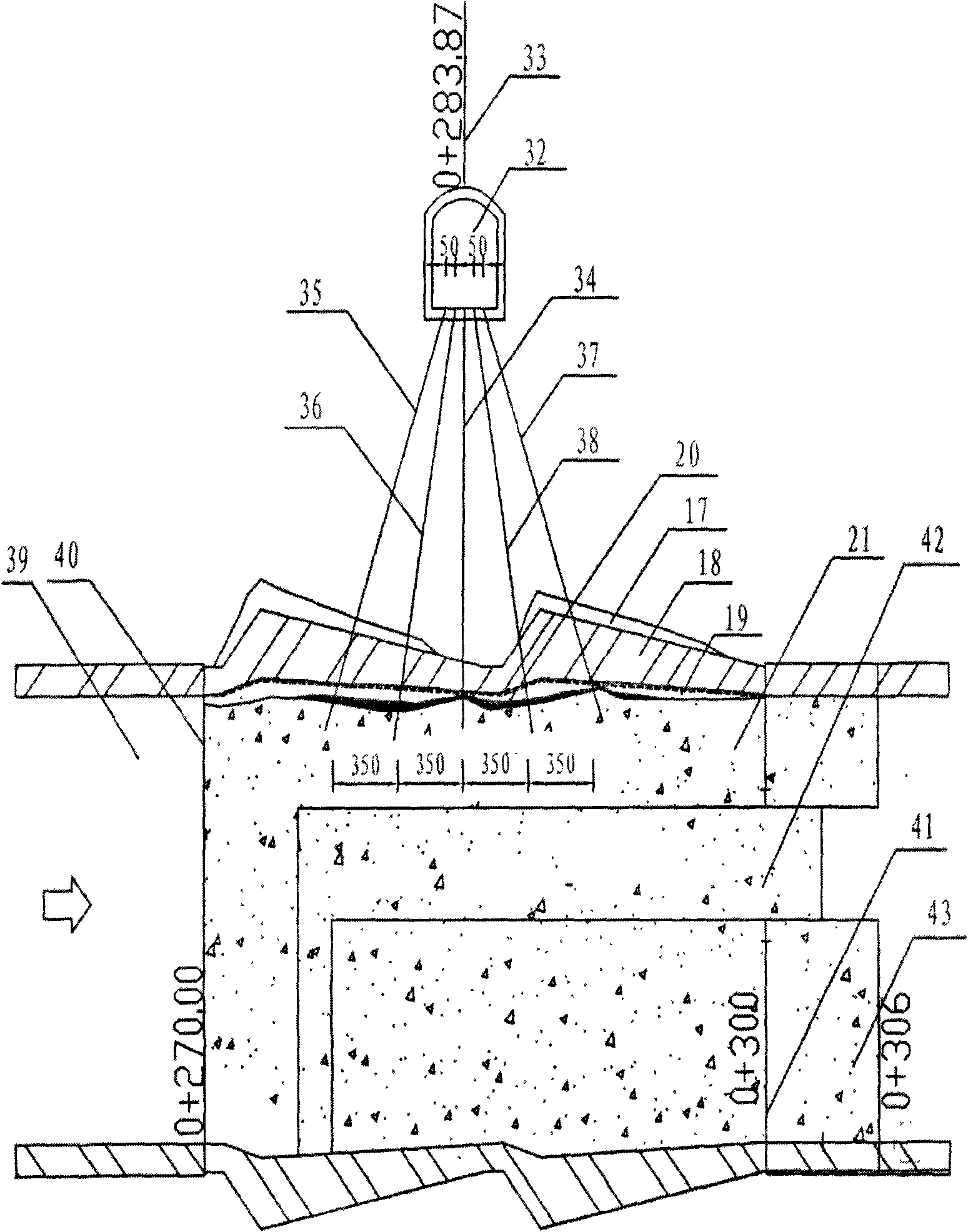

[0049] Example: combined with Figure 1~4 , describe the specific implementation process through construction practice

[0050] 1. Simulation and productive grouting test

[0051] In order to verify the feasibility and safety reliability of the construction scheme design, a simulation test was carried out on the water supply steel pipe with a head pressure of 110m outside the EL.612m auxiliary tunnel from July 7 to July 12, 2008, and the grouting process was obtained. , grouting equipment and grouting material adaptability preliminary data, the effect is obvious. After further refining the construction plan, a productive grouting test was carried out in the EL.612m corridor from November 24th to December 3rd, 2008, and the test was successful, verifying the safety of drilling and grouting under high water head , Fillability, rationality of mechanical equipment configuration and other parameters. Through the test, the implementation details of the original construction plan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com