Rock burst prevention and treatment method based on explosive tamping hydraulic fracturing

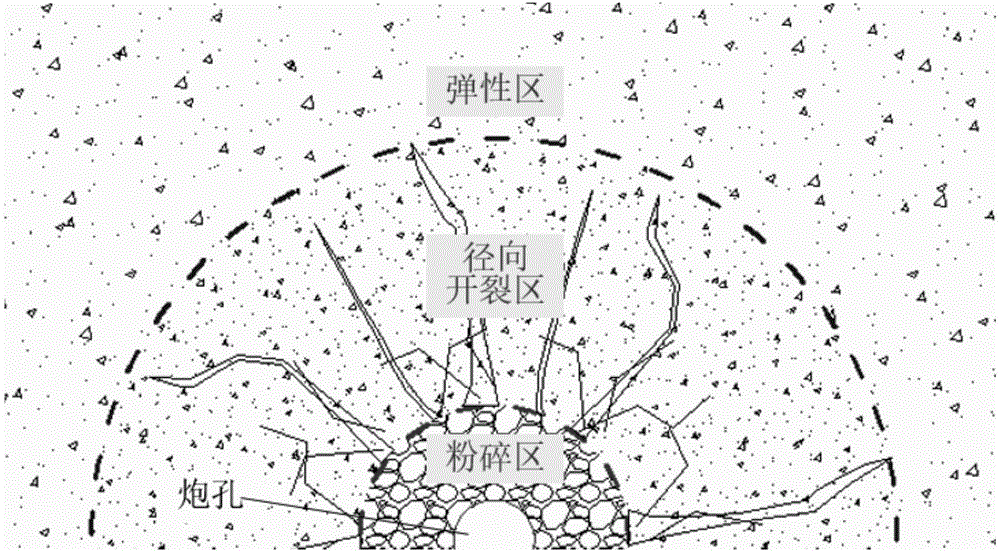

A technology for hydraulic fracturing and rock burst, which is applied in the field of rock burst prevention and control based on hydraulic fracturing by blasting and ramming, and can solve the optimization of the blasting method for stress relief of the detonation network, the transient release of unfavorable excavation loads, and the inability to make full use of explosives. and other problems, to achieve the effect of strengthening the transient unloading effect, improving the effect of rockburst prevention and control, and improving the physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A rockburst prevention and control method based on hydraulic fracturing by explosive ramming, comprising the following steps:

[0057] step one:

[0058] Use PNJ-A type gun mud machine to make gun mud. Local materials can be used to make gunpowder to save costs, and it is made according to the ratio of soil:sand:water=0.75:0.1:0.15. The gun mud should not be too soft or too hard. If it is too soft, it is easy to squeeze out the gun hole. When it is too hard, it is not easy to smash the gun mud, and the blockage is not solid. The finished blasting mud should not be placed for too long, it is best to make it 1-2 hours before use, otherwise it will lose water and become hard, and the effect of dust suppression will be affected after being blocked; Wrap in plastic wrap, or store in a cool place.

[0059] Step two:

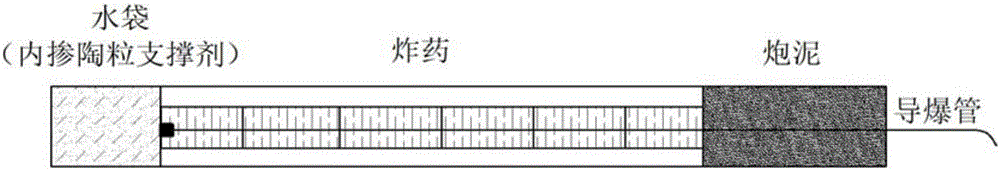

[0060] (1) Select ceramsite proppant. At present, different manufacturers provide ceramsite proppants with different product specifications in the market, ...

Embodiment 2

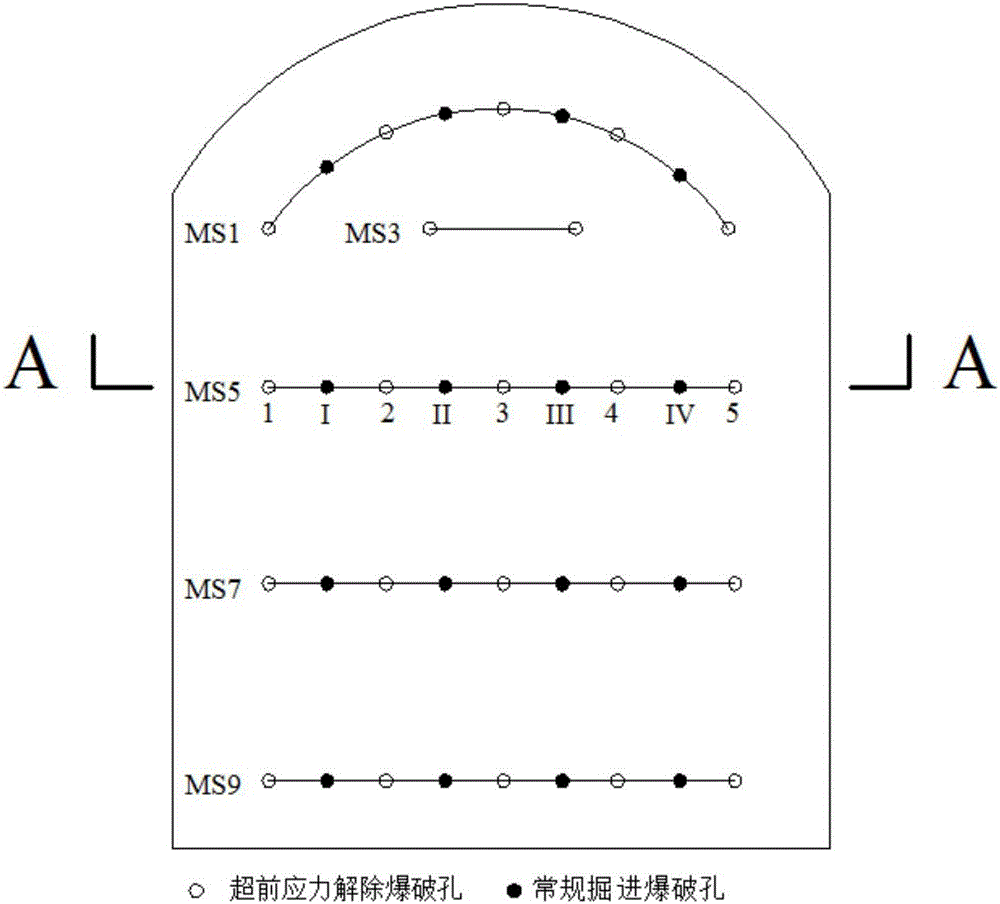

[0077] In order to illustrate the implementation of the method of the present invention, a hole-shaped tunnel surface of a city gate is taken as an example.

[0078] For the drilling and blasting excavation of tunnels with high risk of rockburst, a shorter footage is generally adopted. The conventional excavation and blasting footage used in this embodiment is 2m, so the depth of the blasting hole for the advance stress relief can be set at 4.0~6.0m.

[0079] Strictly control the amount of charge in the blast hole for advance stress relief, and the amount of charge in each blast hole shall not exceed 50% of the charge for loosening blasting under the same conditions. The charge starts from the bottom of the blast hole for stress relief, and the length of the charge section does not exceed 1 / 3 of the depth of the blast hole for stress relief.

[0080] Assume that under the conditions of this embodiment, the depth of the conventional excavation blast hole is 2m, the plugging is 0...

Embodiment 3

[0099] In order to compare the stress relief effect with or without ceramsite proppant, the same charge structure and drilling method were adopted in another excavation footage under the same geological conditions, and ceramsite proppant was not mixed only in the preparation of water bags ( The only difference between Example 3 and Example 2 is that no ceramsite proppant is mixed in the water bag), so as to compare it with the working condition containing ceramsite proppant.

[0100] After the blasting of Example 3, the effect after the blasting of the blast hole is as follows: Figure 5 (b) shown.

[0101] The post-explosion effect of the advanced stress relief blast hole in Example 2 (without ceramsite proppant) is as follows: Figure 5 As shown in (a), the post-explosion effect of the advanced stress relief blast hole (including ceramsite proppant) in Example 3 is as follows: Figure 5 As shown in (b), under the joint action of ceramsite proppant and water, the blasting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com