Construction method of 150m-300m high concrete faced rockfill dam with cemented sand and gravel structure layer

A technology of concrete slab and cementitious gravel, applied in dams, barrages, weirs, etc., can solve the problems of high slump, large cement consumption, loss of water retaining function of dams, etc., and achieve the effect of improving coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Now in conjunction with the accompanying drawings, the specific implementation of the present invention will be described in detail.

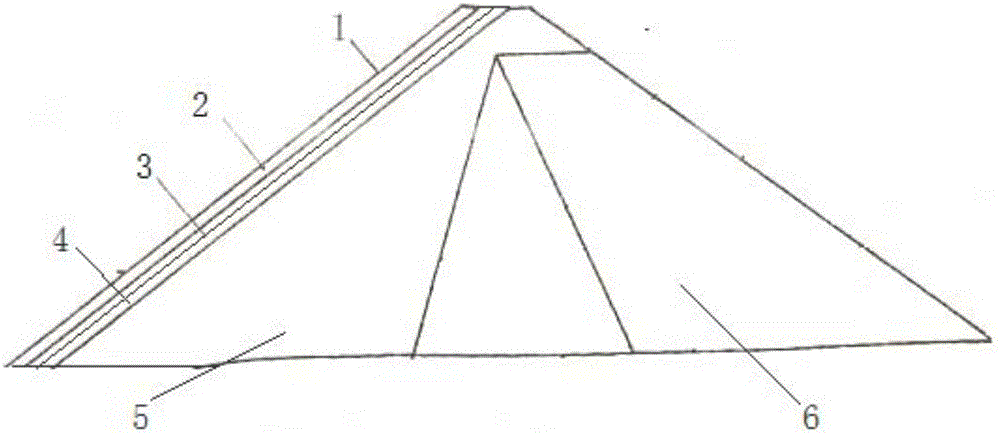

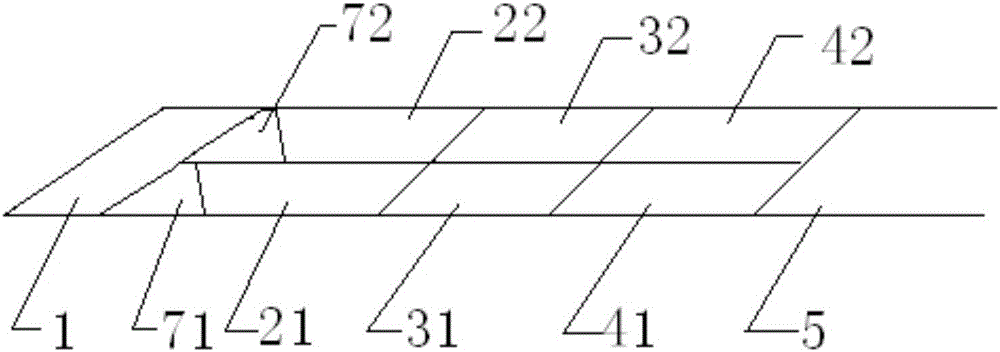

[0053] Such as figure 1 and figure 2 As shown, the construction method of the 150m to 300m high concrete face rockfill dam with a cemented sand and gravel structure layer added in the present invention includes a concrete face plate 1, a cemented sand and gravel structure layer 2, a cushion layer area 3, and a transition area 4 , main rockfill area 5 and secondary rockfill area 6, said method comprises the steps:

[0054] Step 1 paving and rolling the stone material in the main rockfill area 5, the thickness of the rolling layer is 80cm;

[0055] Step 2 Construction transition zone, cushion zone, concrete extruded side wall and cemented sand and gravel structure layer:

[0056] 2.1 Spread rolling transition material, cushion material, concrete extrusion side wall construction and laying roller compacted gelled sand and gravel materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com