A multi-purpose pump system

A pump system and multi-purpose technology, applied in heat pumps, refrigeration components, refrigerators, etc., can solve problems such as pollution, leakage of organic working fluid, and lack of absorption heat energy for utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

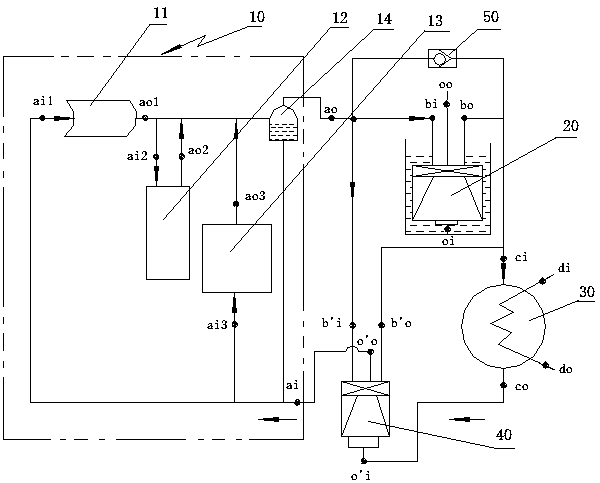

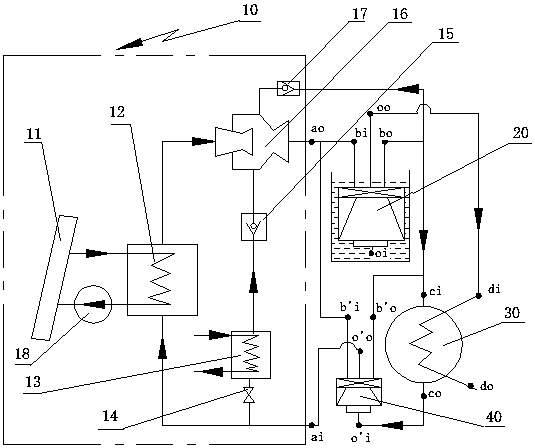

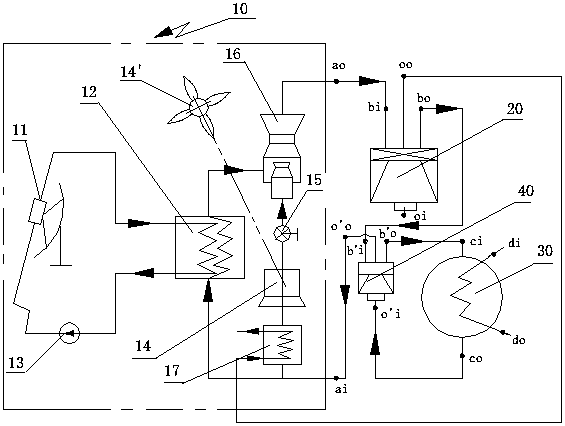

[0049] attached figure 1 The utility model is a multi-purpose pump system of the present invention that mainly absorbs and utilizes solar energy and is supplemented by other energy sources for transporting liquids and lowering the ambient temperature. The thermal power unit 10 is a thermal power generating subsystem that operates jointly with solar energy, auxiliary heat source, and heat storage. Groove 12, gas-liquid separator 14 etc. are formed, and solar heat collector 11 is connected in parallel with auxiliary energy steam generator 13, and heat storage tank 12 is connected on the air outlet pipeline of solar collector 11 and auxiliary energy steam generator 13, The inlet port of the gas-liquid separator 14 is connected in series with the common gas outlet port of the auxiliary energy steam generator 13 and the solar collector 11, and the gas outlet port of the gas-liquid separator 14 is used as the gaseous working medium gas outlet port ao of the thermal power unit 10 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com