Method for modifying and exploiting oil shale in situ through fluid

An oil shale, first fluid technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of difficult fluid heating, high energy consumption, low electric heating efficiency, etc., to prevent rapid channeling flow, the effect of expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

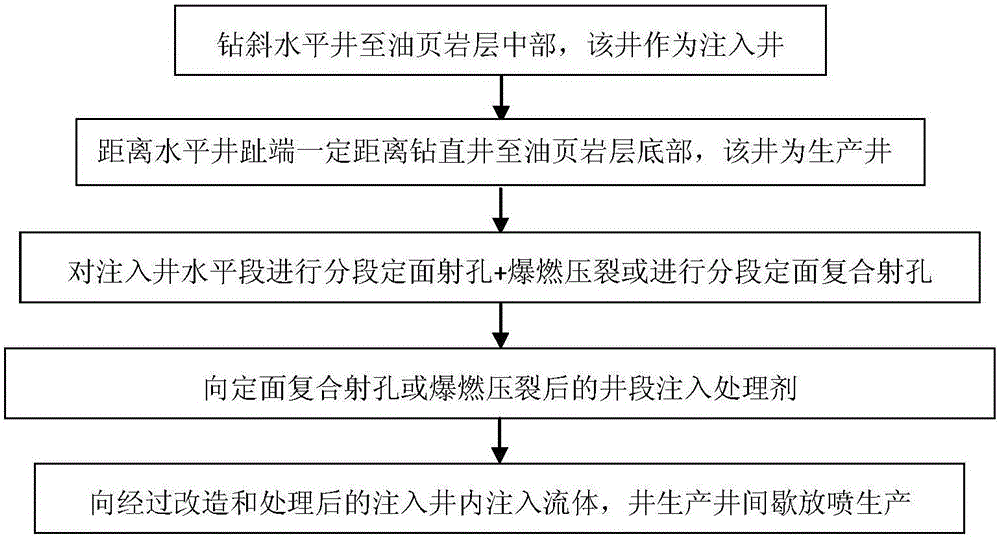

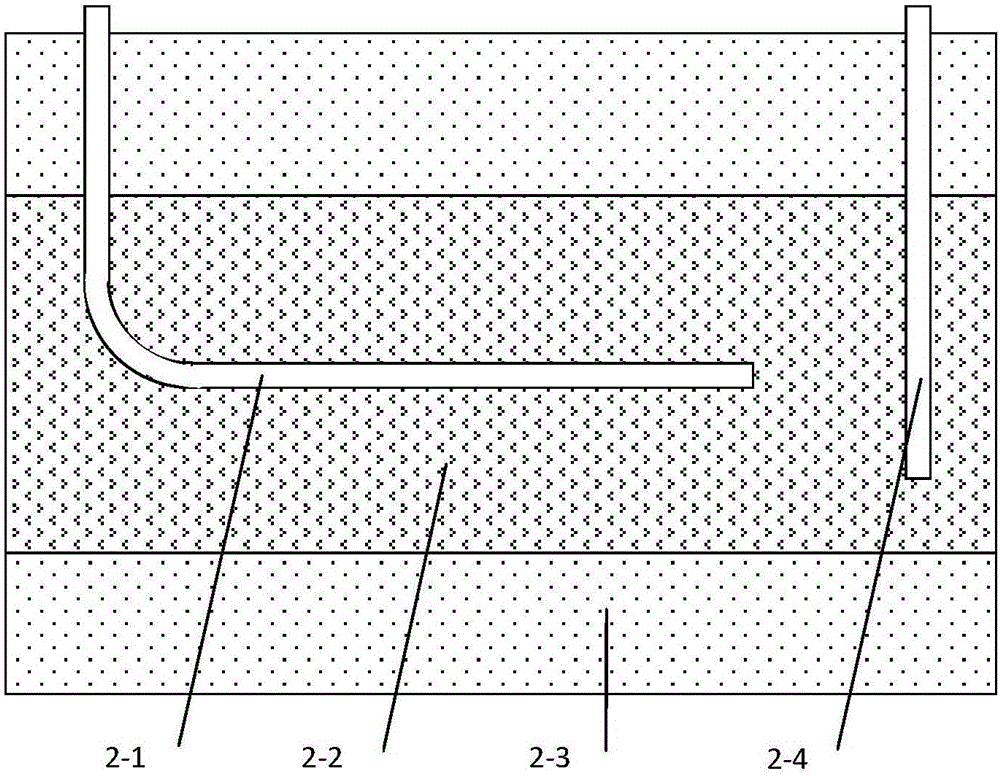

[0054] Such as figure 2 As shown, using the method of the present invention, in a near-horizontal single oil shale mineral layer with a thickness of 12m and an average burial depth of the oil shale top interface of 94m, arrange 2 wells (1 injection well+1 production well) . The specific steps are:

[0055] 1) An inclined horizontal well is drilled in parallel from the ground to the middle of the oil shale layer (depth 100m) as an injection well. The length of the horizontal section is 40m, and the horizontal section is completed with open holes. Drill a vertical well 5m from the toe of the horizontal well to the bottom of the oil shale layer (depth 104m) as a production well.

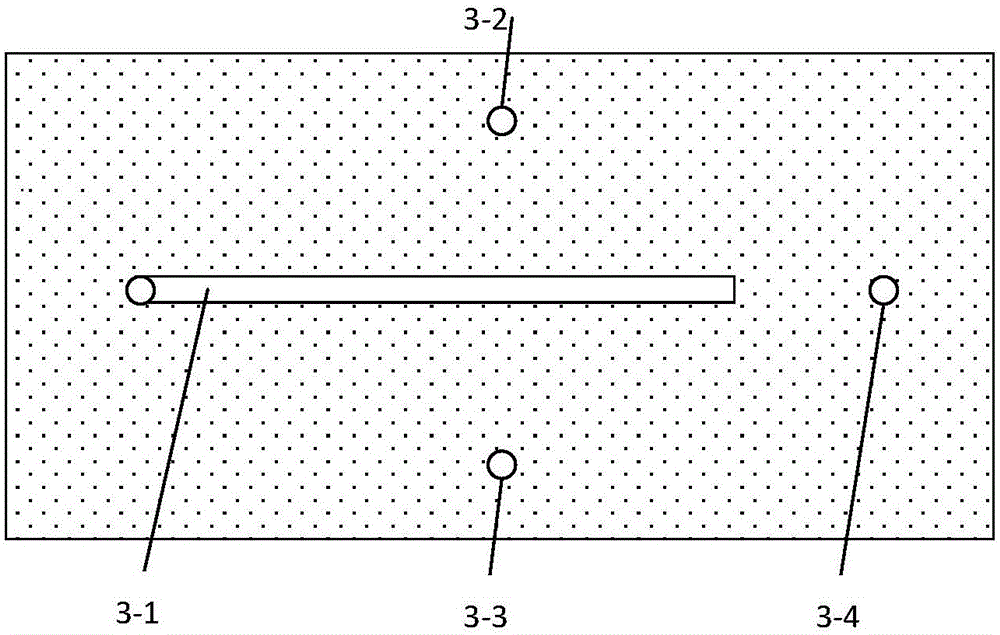

[0056] 2) if Figure 7 As shown in Fig. 1, the horizontal section of the injection well is subjected to segmented fixed-surface compound perforation. Every 10m section from the toe to the heel of the horizontal well is divided into four sections, and fixed-surface compound perforation is carried ou...

Embodiment 2

[0063] Such as figure 2 As shown, adopt the method of the present invention, in a thickness be 28m, the average burial depth of oil shale reservoir top surface is 786m in the nearly horizontal single oil shale mineral layer, arrange 2 wells (1 injection well+1 production well well). The specific steps are:

[0064] 1) An inclined horizontal well is drilled in parallel from the ground to the middle of the oil shale layer (800m deep) as an injection well. The length of the horizontal section is 60m, and the horizontal section is completed with open holes. Drill a vertical well 9m from the toe of the horizontal well to the bottom of the oil shale layer (810m deep) as a production well.

[0065] 2) if Figure 5 and Figure 6 As shown in Fig. 1, the horizontal section of the injection well is reconstructed by first perforating the surface and then deflagration fracturing. Every 20m section from the toe to the heel of the horizontal well is divided into three sections, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com