Shredding device for production of non-fried instant noodles

A non-fried instant noodle and shredded technology, which is applied in the field of instant noodle production equipment, can solve the problems of lumpy agglomeration of noodle cakes, high water content on the surface of noodles, and uneven quality of noodle cakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments.

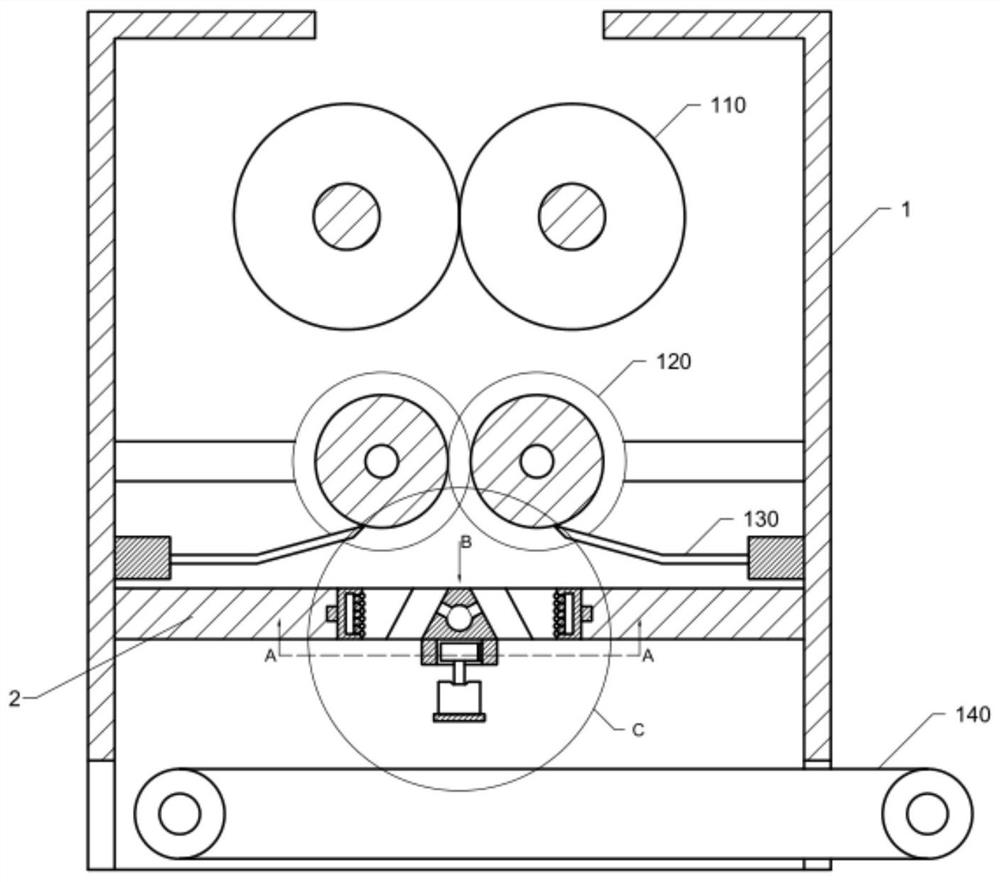

[0031] Such as Figure 1 to Figure 4 As shown, this specification provides an embodiment, a kind of non-fried instant noodles, including a mounting frame 1, and the mounting frame 1 is installed on the production line. ;

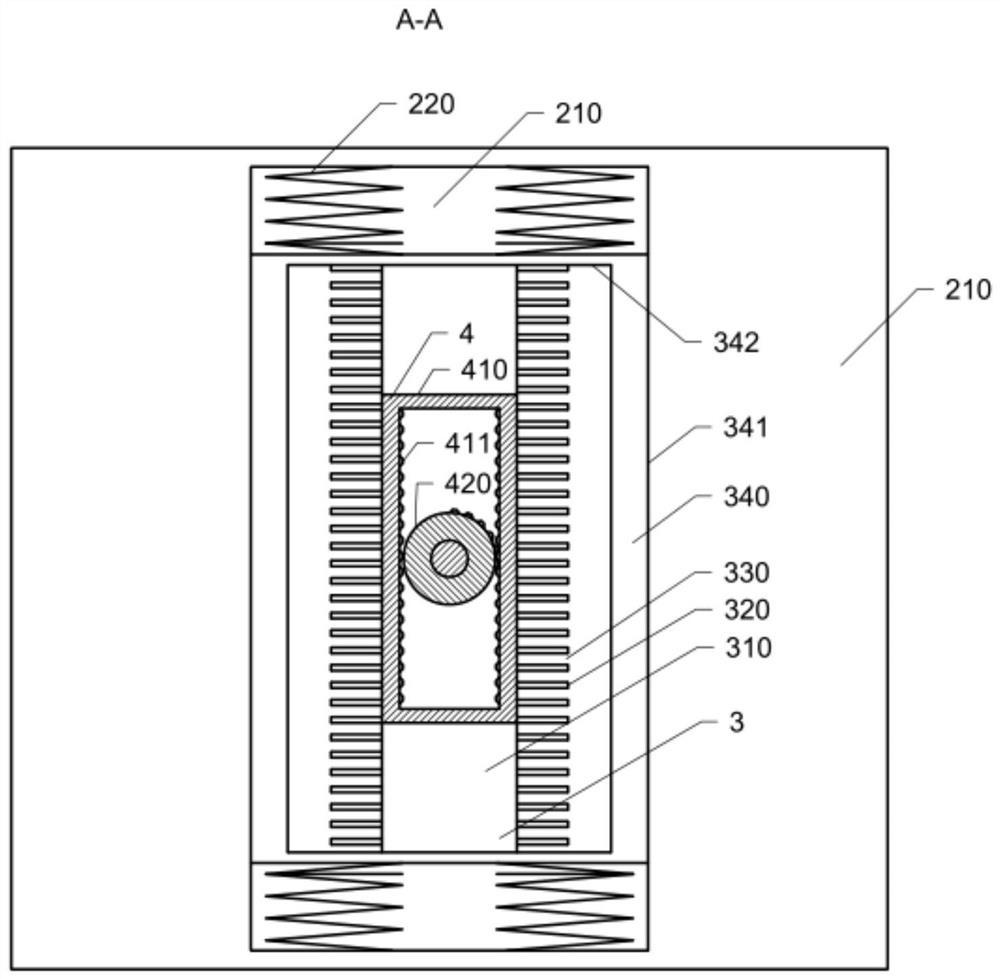

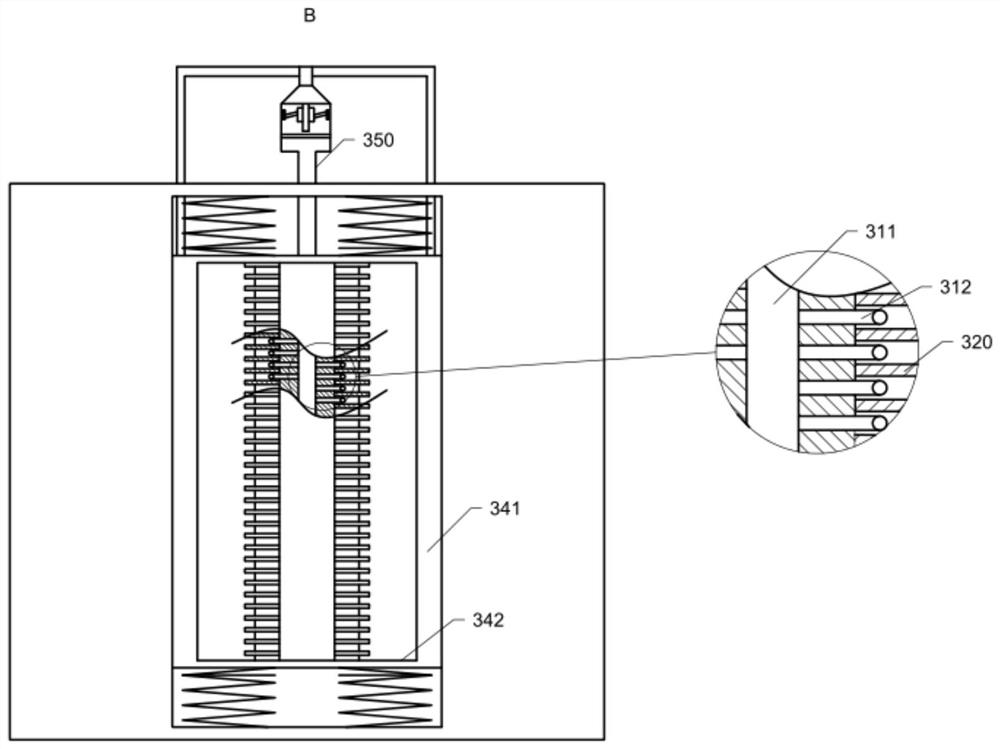

[0032] Rotate the calendering roller 110 located at the upper end of the mounting frame 1, detachably be located on the mounting frame 1 and the shred cutter 120 below the calendering roller 110, be detachably arranged on the mounting frame 1 and fit with the shredding knife 120 The set copper comb 130, the wave-making net 140 at the bottom of the installation frame 1, and the loose components between the shredding knife 120 and the wave-making net 140; Therefore, it is installed on the installation frame 1 by bolt connection, which is convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com