Waste molding sand or core sand regenerating equipment

A technology for recycling equipment and molding sand, which is applied to casting molding equipment, metal processing equipment, and machinery for cleaning/processing casting materials, etc. It can solve problems such as low thermal efficiency, general processing effect, and limited processing capacity, and achieve smoke exhaust loss. Low, improve thermal efficiency, enhance the effect of mutual collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

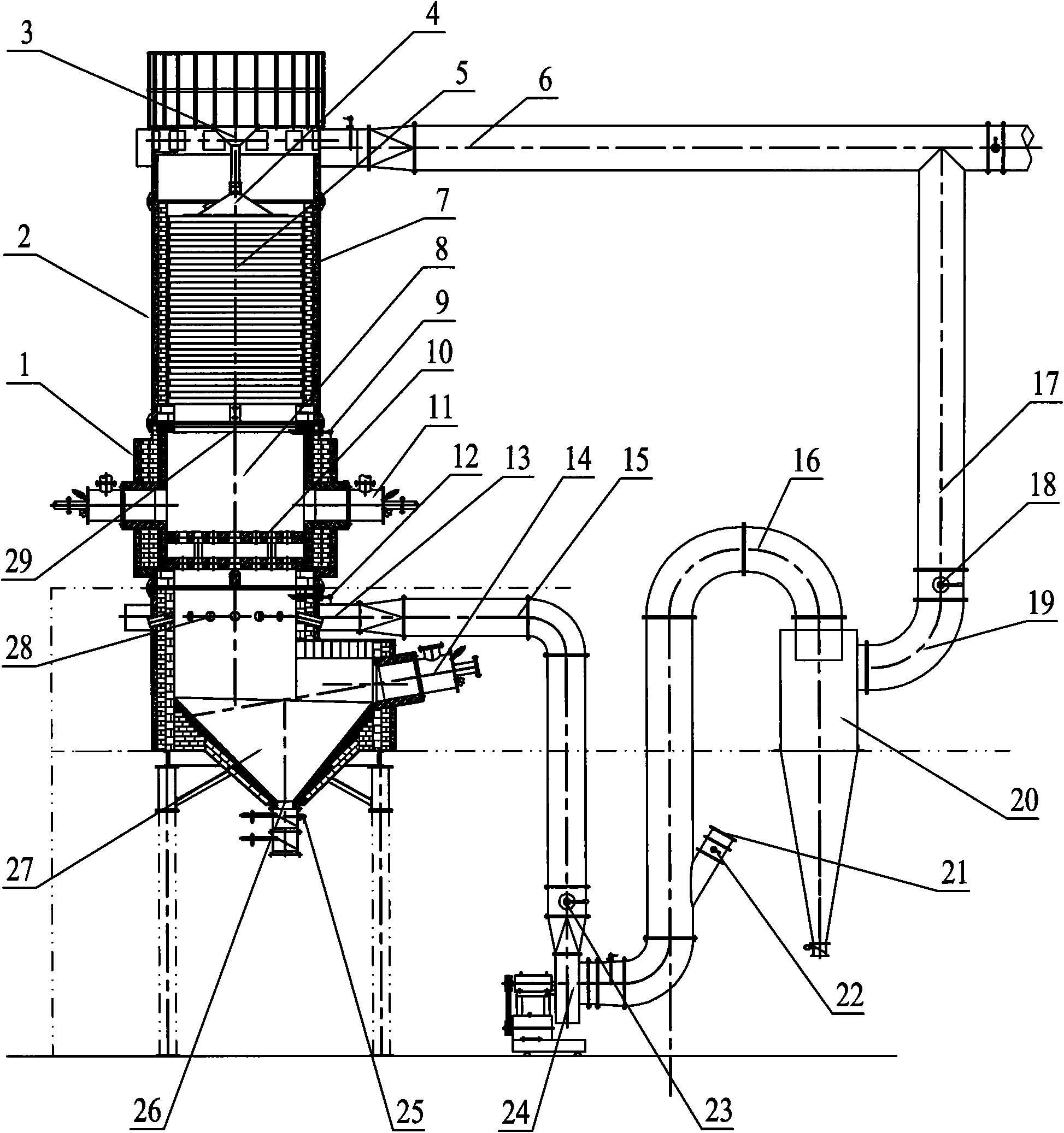

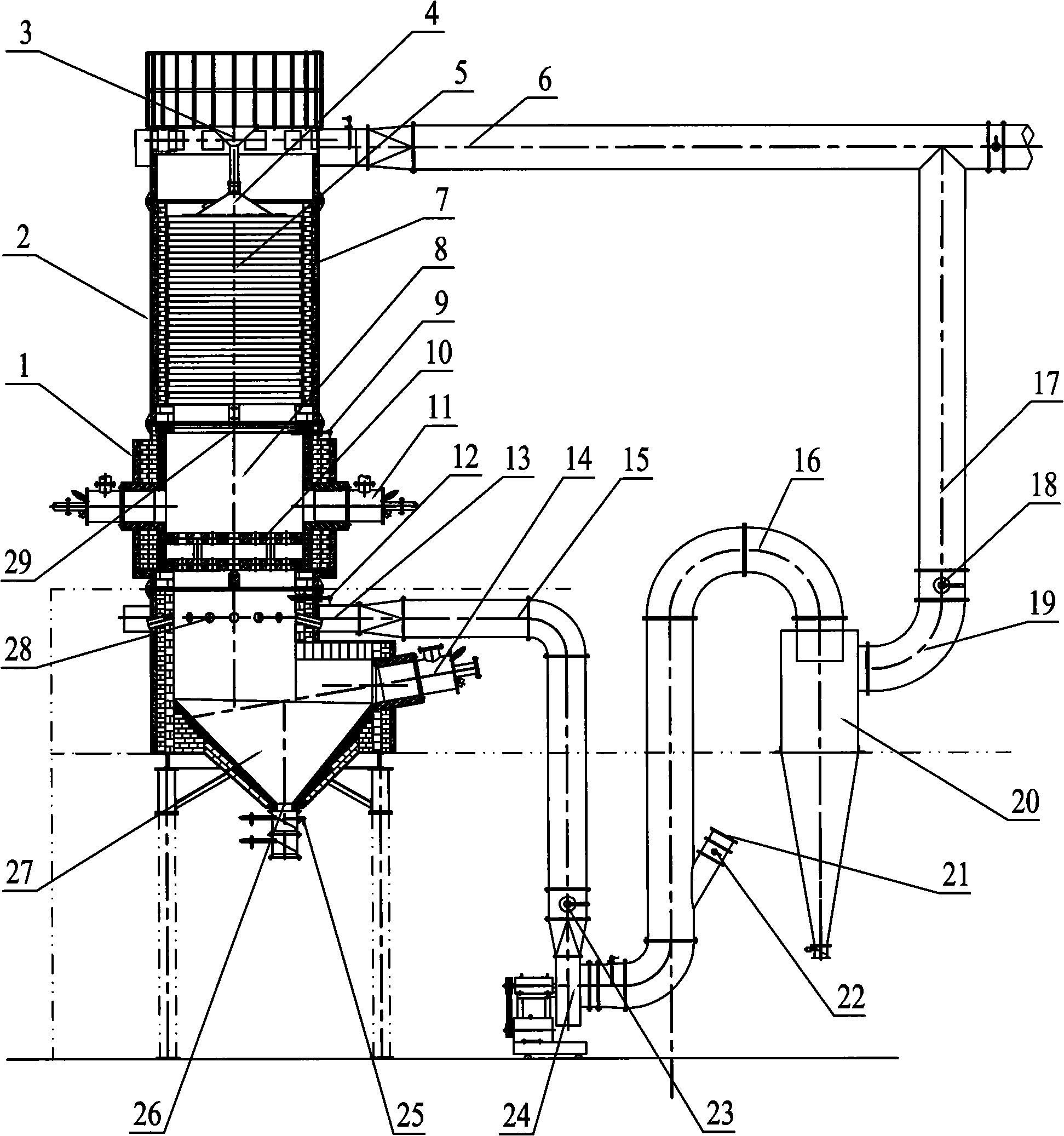

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0018] As shown in the figure, the present invention mainly consists of a fluidized roasting furnace 1 and a sand dividing heating device 2 . The fluidized roasting furnace 1 is provided with a roasting inlet 29, a roasting outlet 26, an air inlet channel and an air outlet channel; the sand dividing heating device 2 is located above the fluidized roasting furnace 1, and the sand dividing heating device 2 includes Chamber 7 and the sand-splitting heating beam 5 and the sand-splitting cone 4 installed in the sand-splitting heating chamber 7, the bottom of the sand-splitting cone 4 is provided with a hole for the mold (core) sand to pass through, and the sand-splitting heating beam 5 is formed by The multi-layer orifice plate is superimposed and fixed, and the orifice plate is also provided with a hole for the mold (core) sand to pass through; the top and bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com