Double energy collection stepping water boiler

A step-by-step, water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of energy waste and low thermal efficiency, save electricity, improve heating efficiency, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

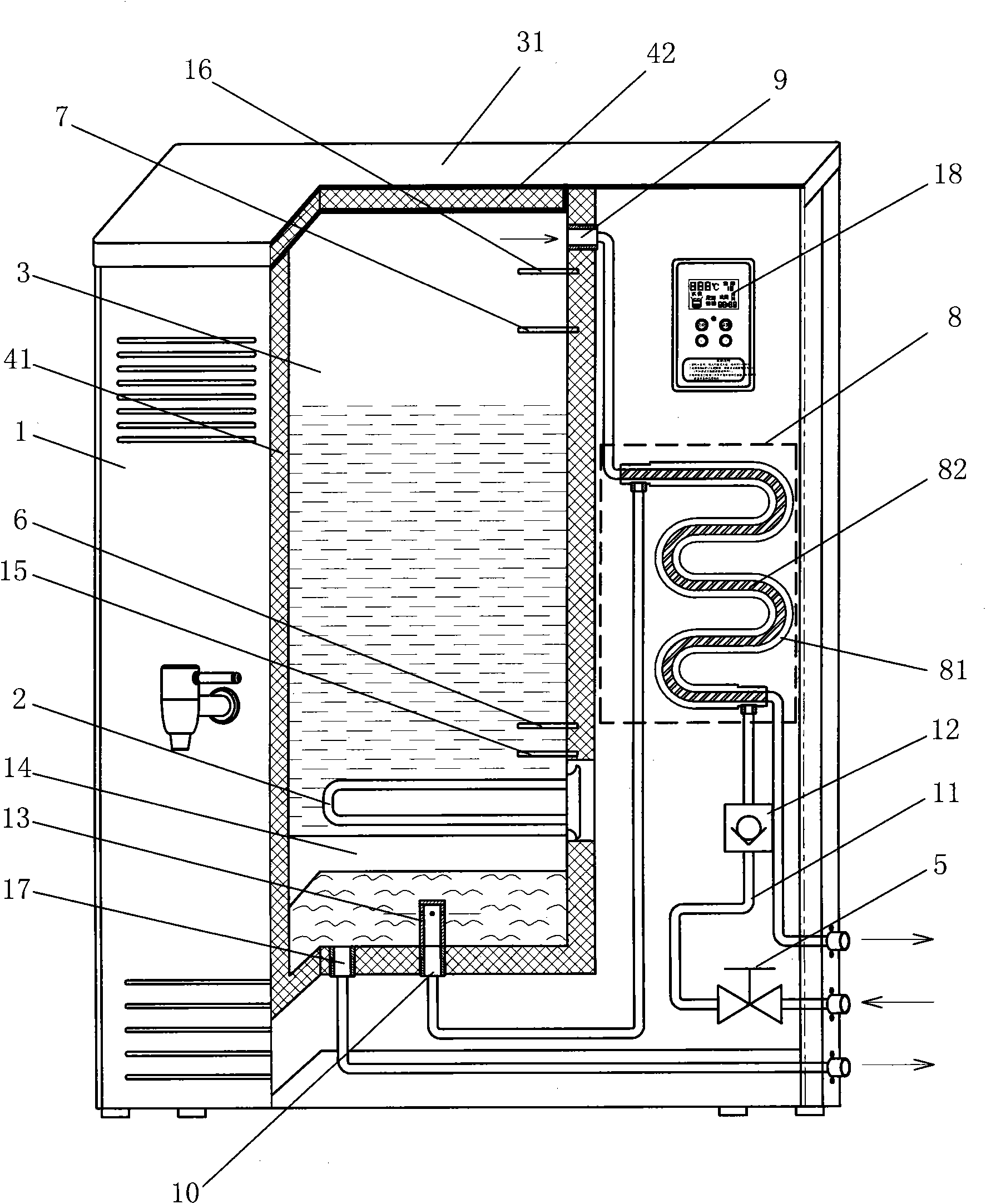

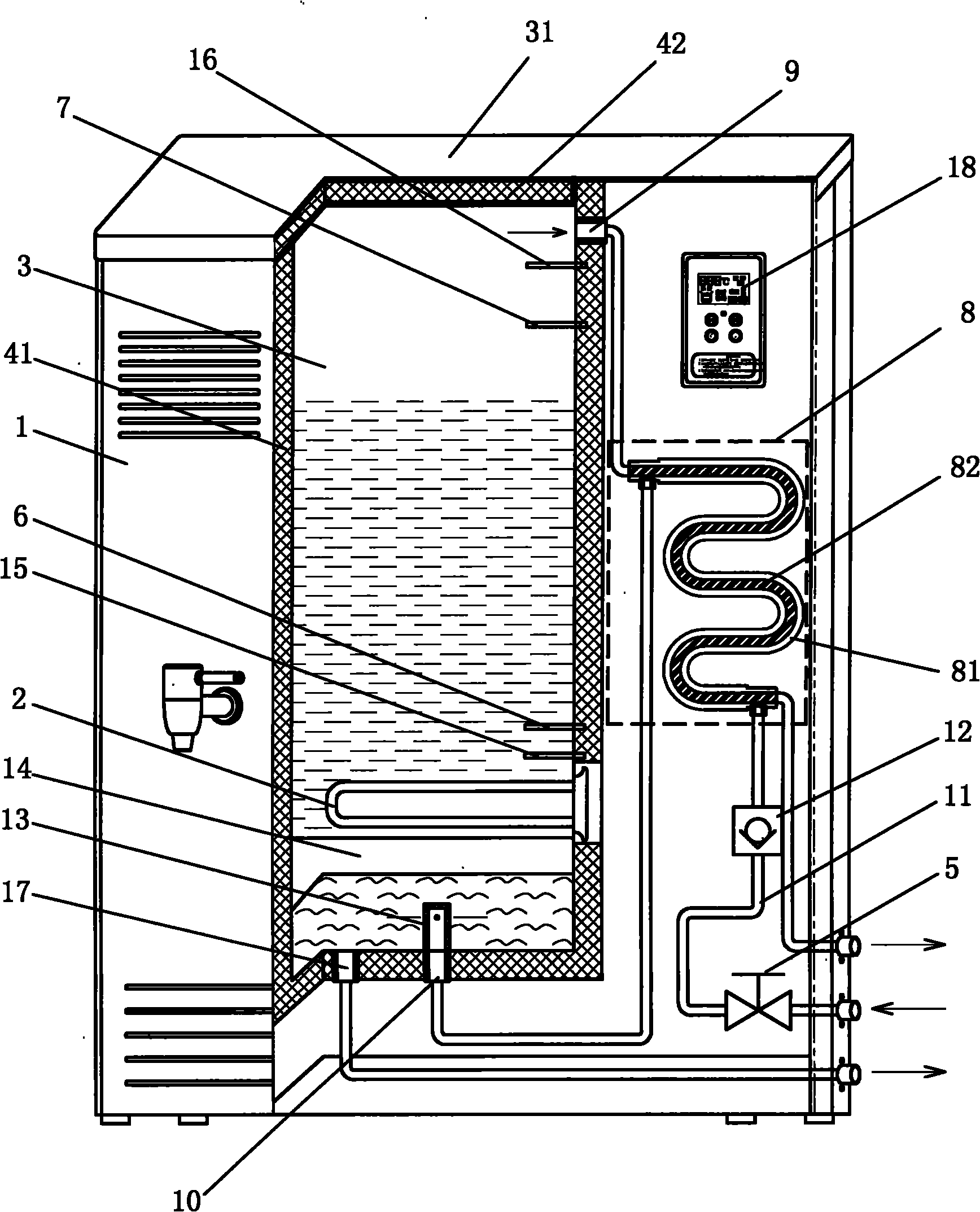

[0025] Embodiment one: if figure 1 Shown, a kind of dual energy-gathering stepping water boiler, it comprises housing 1, electric heater 2, electric control device 18, water inlet solenoid valve 5, high and low water level electrodes 6,7 and heat energy recovery device 8, The housing 1 is provided with a stainless steel water tank 3, the bottom of the water tank 3 and its side walls are all provided with an insulating layer 41, and the top 31 of the water tank 3 is provided with an insulating layer 42, and the water boiler also includes an inlet Water solenoid valve 5, high and low water level electrodes 6 and 7 and heat energy recovery device 8, high and low water level electrodes 6 and 7 are installed in the water tank 3, and the top of the water tank 3 also has a steam outlet 9, and the heat energy recovery device 8 is installed in the water tank 3 On the side of the water tank 3 in the housing 1, the heat recovery device 8 is a heat exchange body composed of an outer tube ...

Embodiment 2

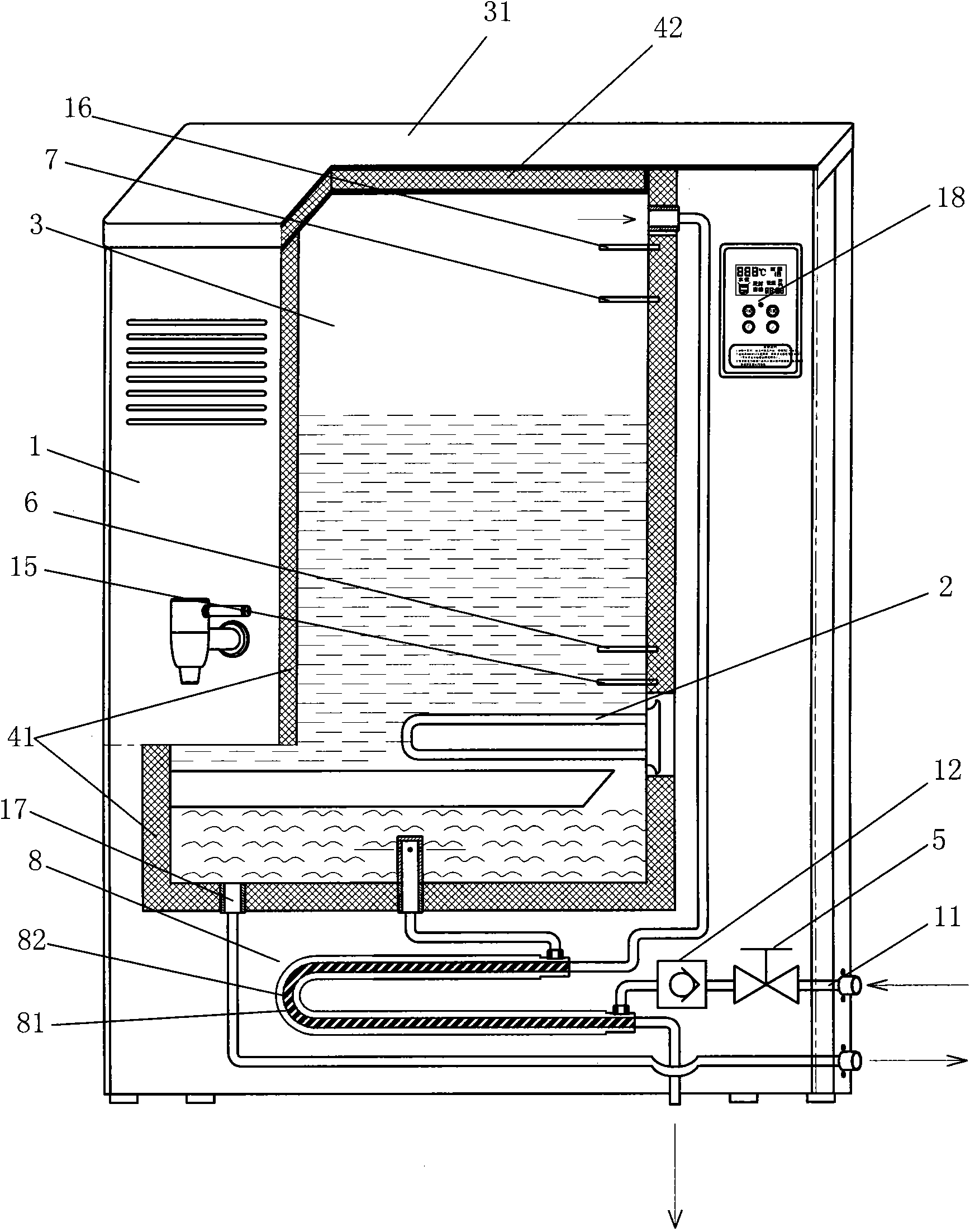

[0032] Embodiment two: if figure 2 As shown, this embodiment is similar to the first embodiment above, the only difference is that the heat energy recovery device 8 is installed under the bottom of the water tank 3 in the housing 1, and the inner and outer tubes 81, 82 are coiled into a curved shape, so as to Extend the path for steam and tap water to pass through. The working principle of this embodiment is the same as that of Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com