Organic fertilizer screening equipment with low damage percentage

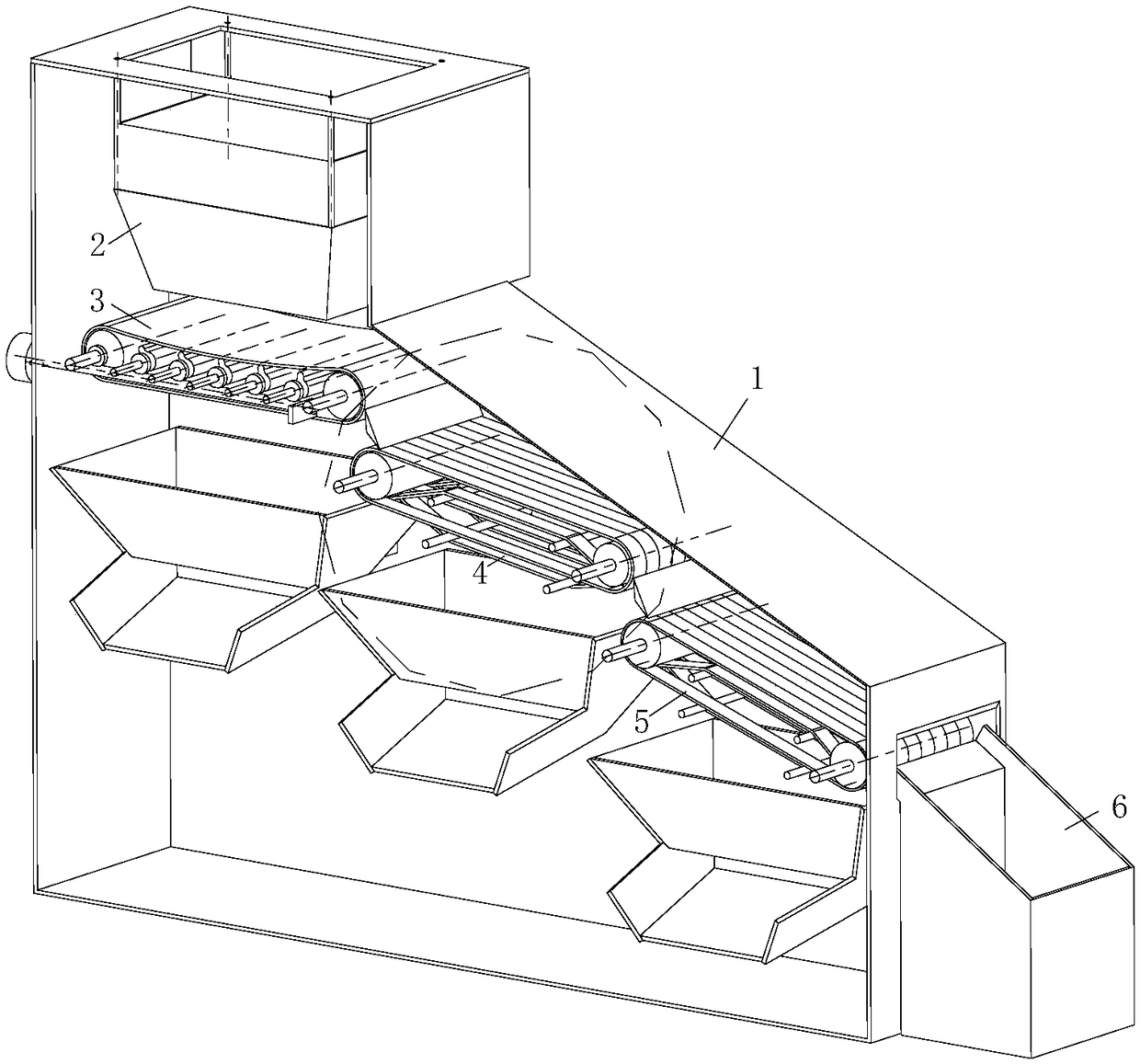

A screening equipment, organic fertilizer technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of particle crushing, affecting the yield, collision, etc., to improve dredging, improve screening efficiency, improve screening effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

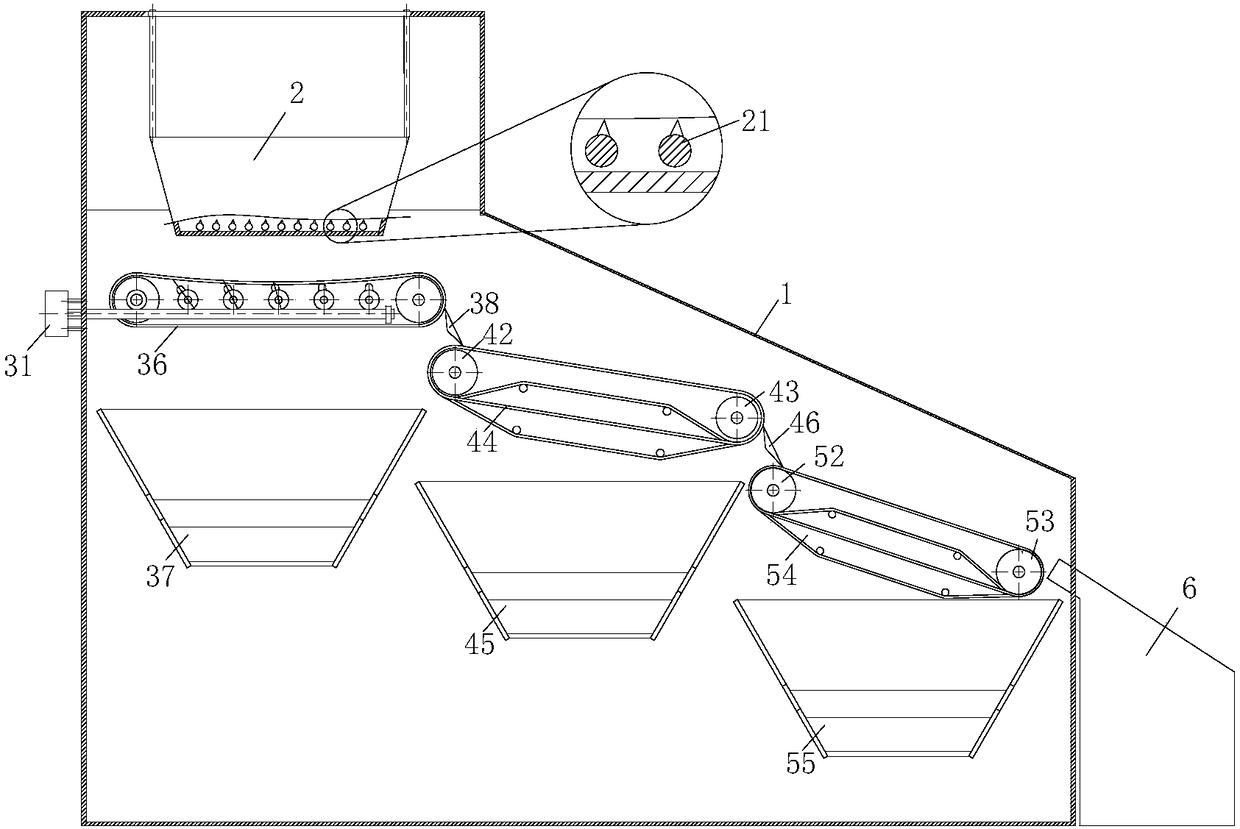

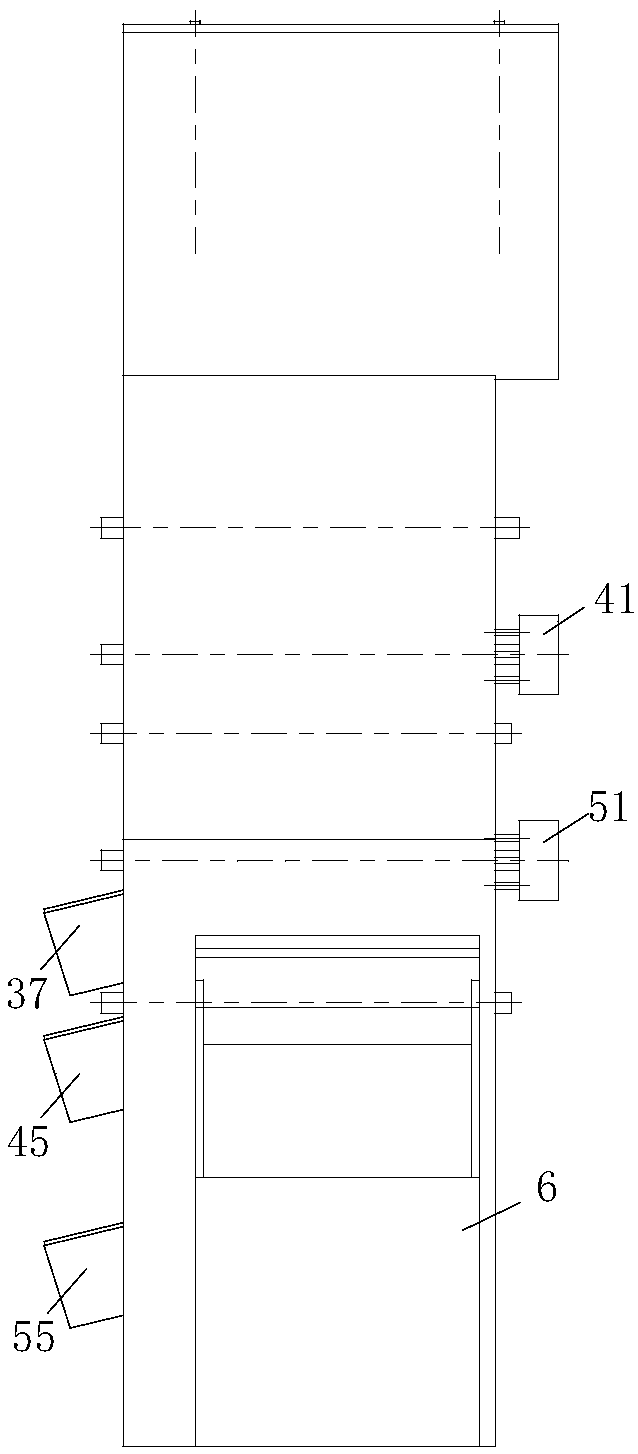

[0045] As an embodiment of the present invention, the pusher device 34 includes a set of pusher shafts 341 arranged in parallel; the pusher shafts are correspondingly provided with a pusher wheel 342; the pusher wheel 342 and the worm 32 drive Connect; the pusher shaft 341 is respectively provided with a pusher cam 343, and the elastic conveyor belt 36 bends downwards after carrying the organic fertilizer, and the elastic conveyor belt 36 at the contact point undulates up and down by the pusher cam 343 to improve the screening efficiency.

[0046] As an embodiment of the present invention, the angle between the pushing cam 343 and the horizontal plane increases sequentially; the pushing cam 343 is used to lift up the elastic conveyor belt 36 sequentially, and push the organic fertilizer to the second screening unit 4 .

[0047] As an embodiment of the present invention, a filter screen is provided at the lower end of the hopper 2; the filter screen is used to intercept bulk ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com