Sewing machines

A sewing machine and needle technology, applied in the field of sewing machines, achieves the effects of simple mechanism, improved reliability and reduced processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. However, the scope of the present invention is not limited to the illustrated examples.

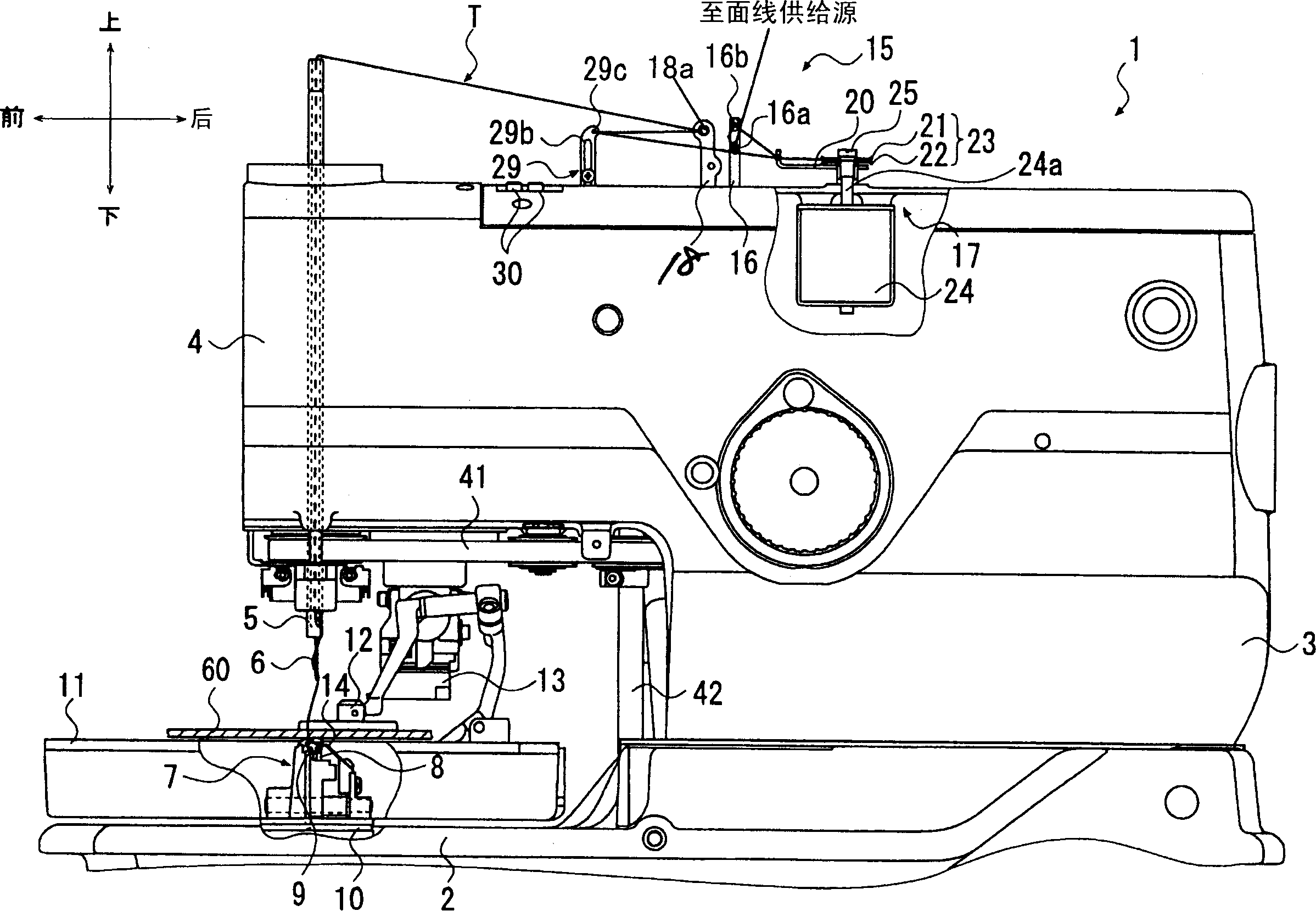

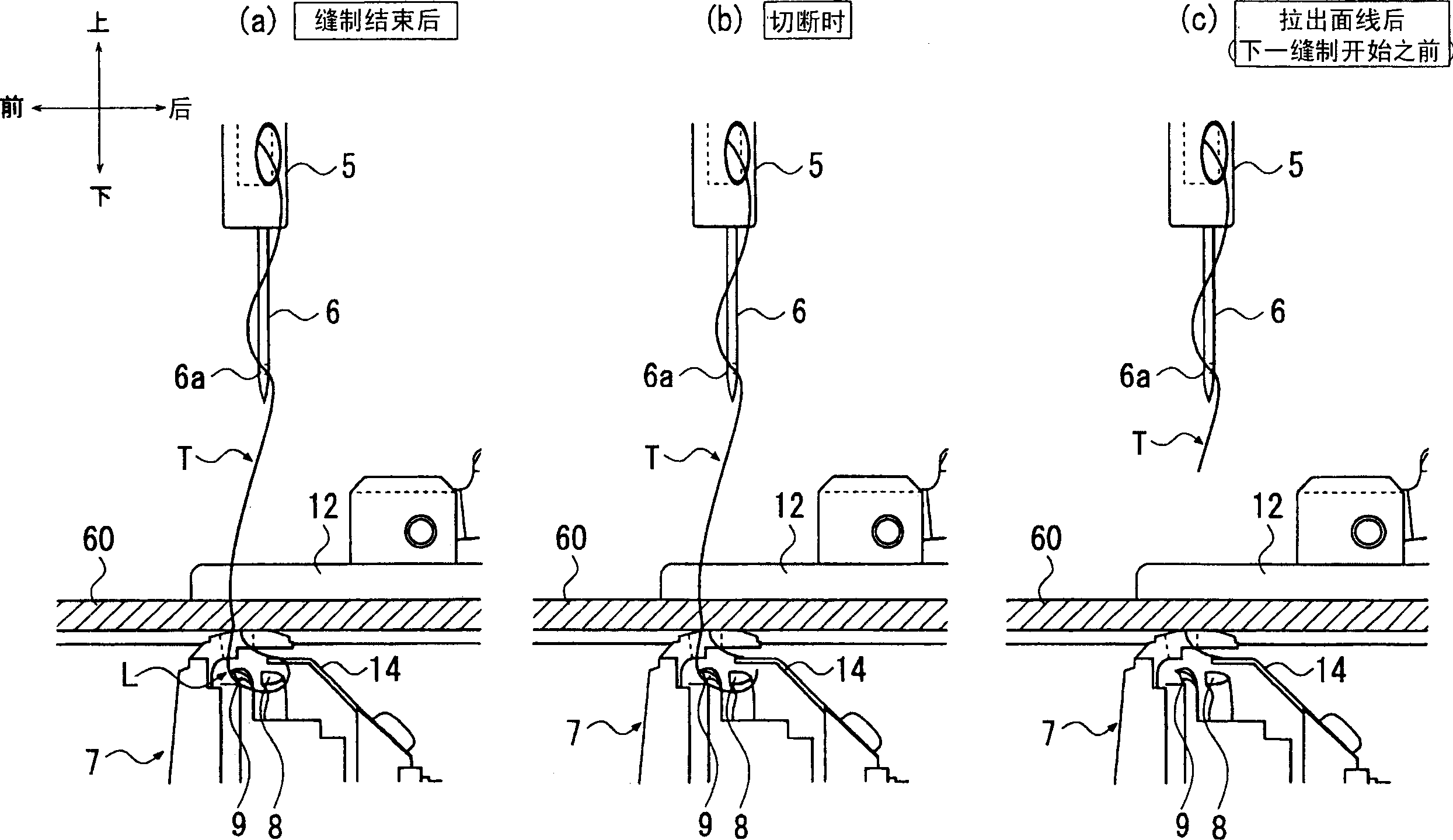

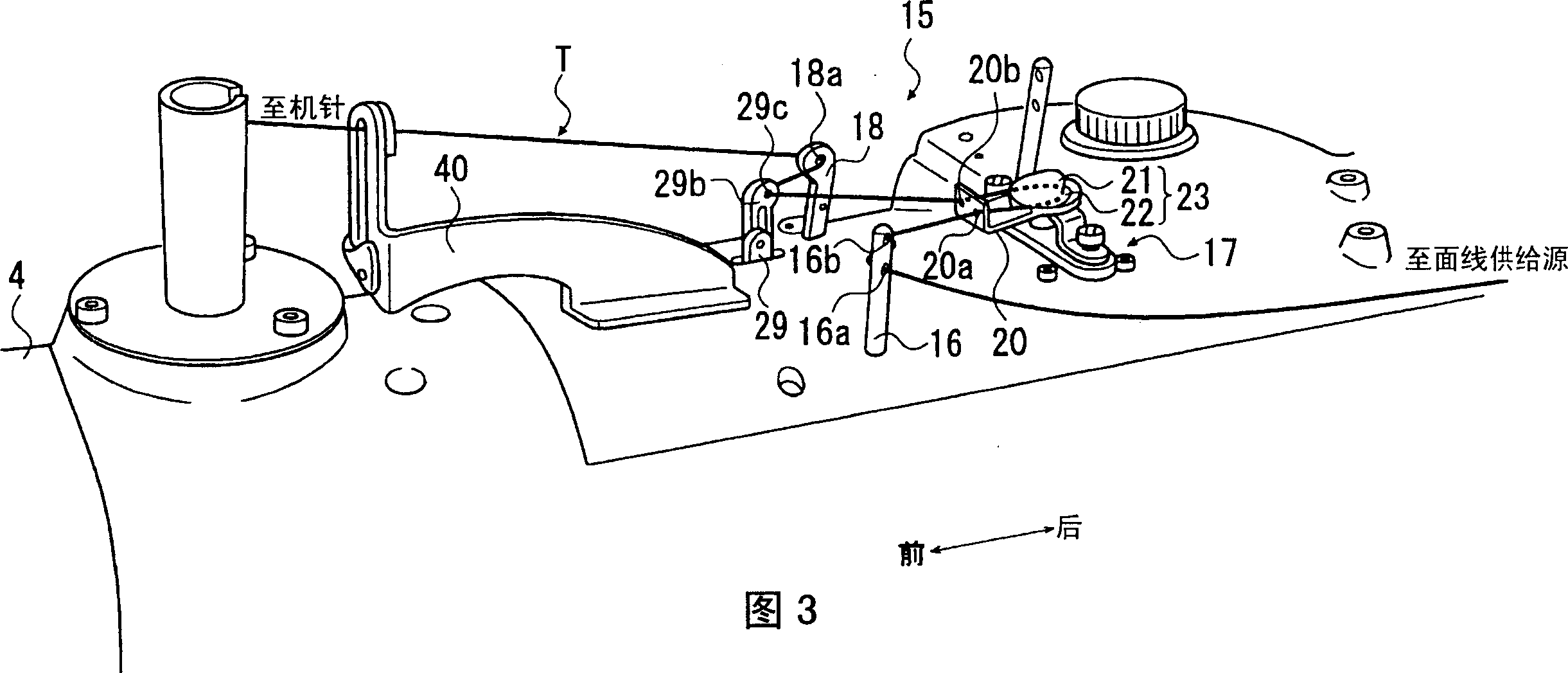

[0050] figure 1 The shown buttonhole sewing machine 1 for buttonhole has a base part 2 in a substantially rectangular box shape, a vertical body part 3 standing upright on the rear end of the frame part 2, and a vertical body part 3 from the vertical body part 3. The upper part of the machine part 2 is slightly parallel to the machine head 4 extending forward, and the needle bar 5 passing through the front end of the machine head 4 up and down, and the machine needle 6 installed on the lower end of the needle bar 5, and The thread shuttle mechanism 7 which is arranged directly below the machine needle 6 in the machine table part 2, and the control device 50 which controls the sewing machine 1 as a whole ( Figure 5 shown).

[0051] A pair of presser feet 12 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com