Wire feeding device of sewing machine

A thread feeding device and sewing machine technology, applied in the direction of sewing machine metering device, sewing machine components, sewing equipment, etc., can solve the problems of poor thread tightness, trouble, thread breakage, etc., and achieve the effect of simplifying cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, preferred embodiments of the thread feeding device of the sewing machine according to the present invention will be described based on the drawings.

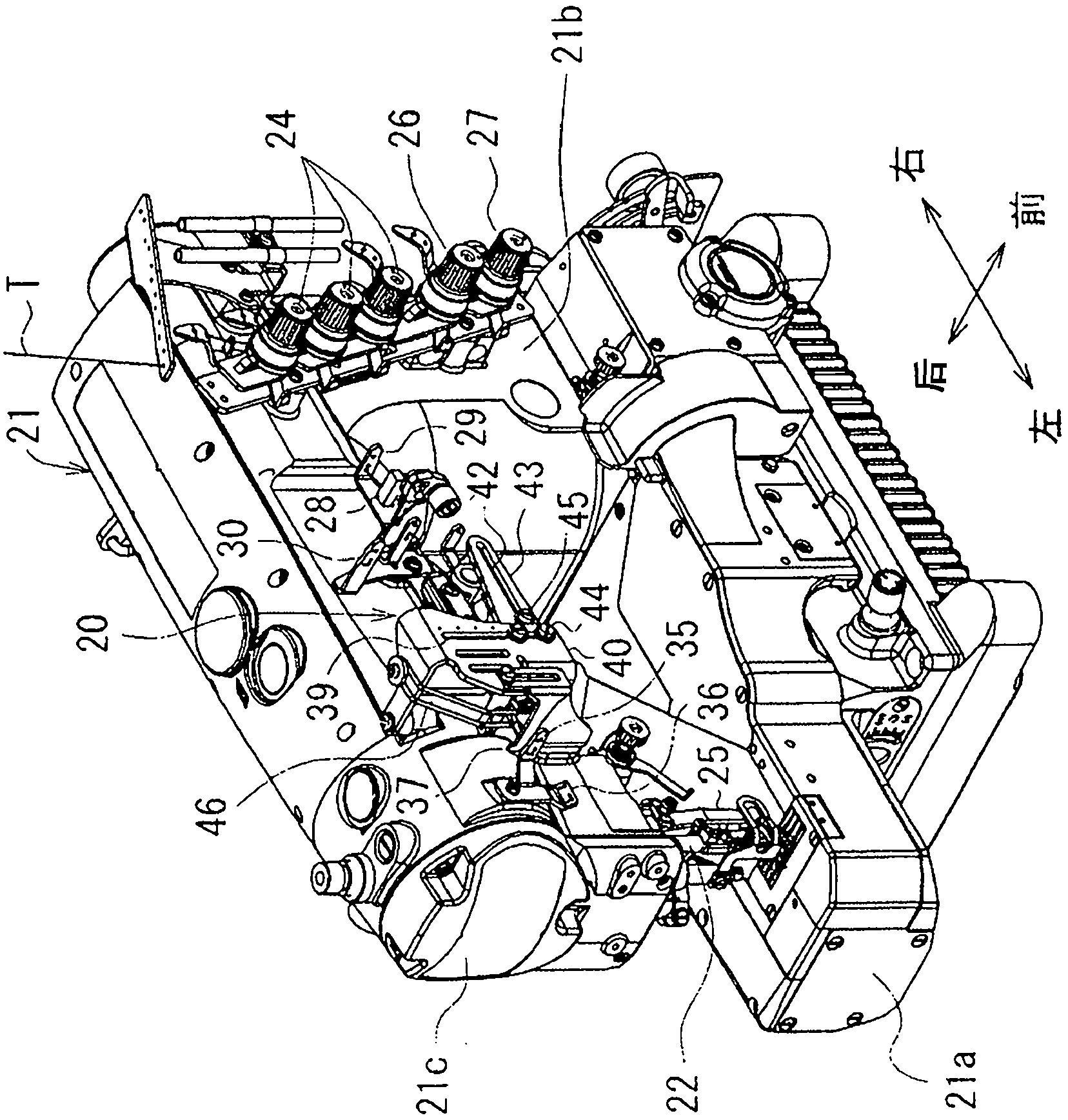

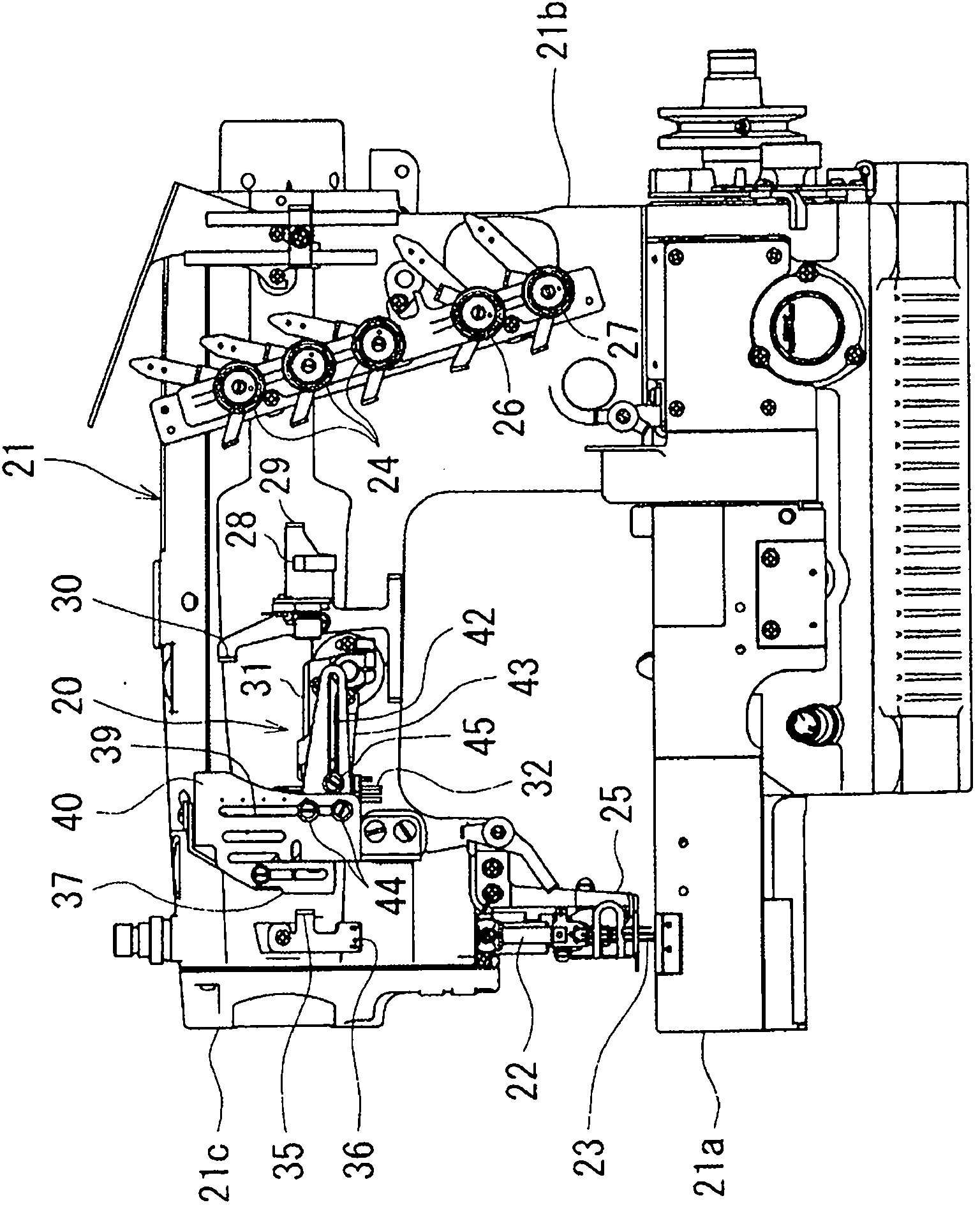

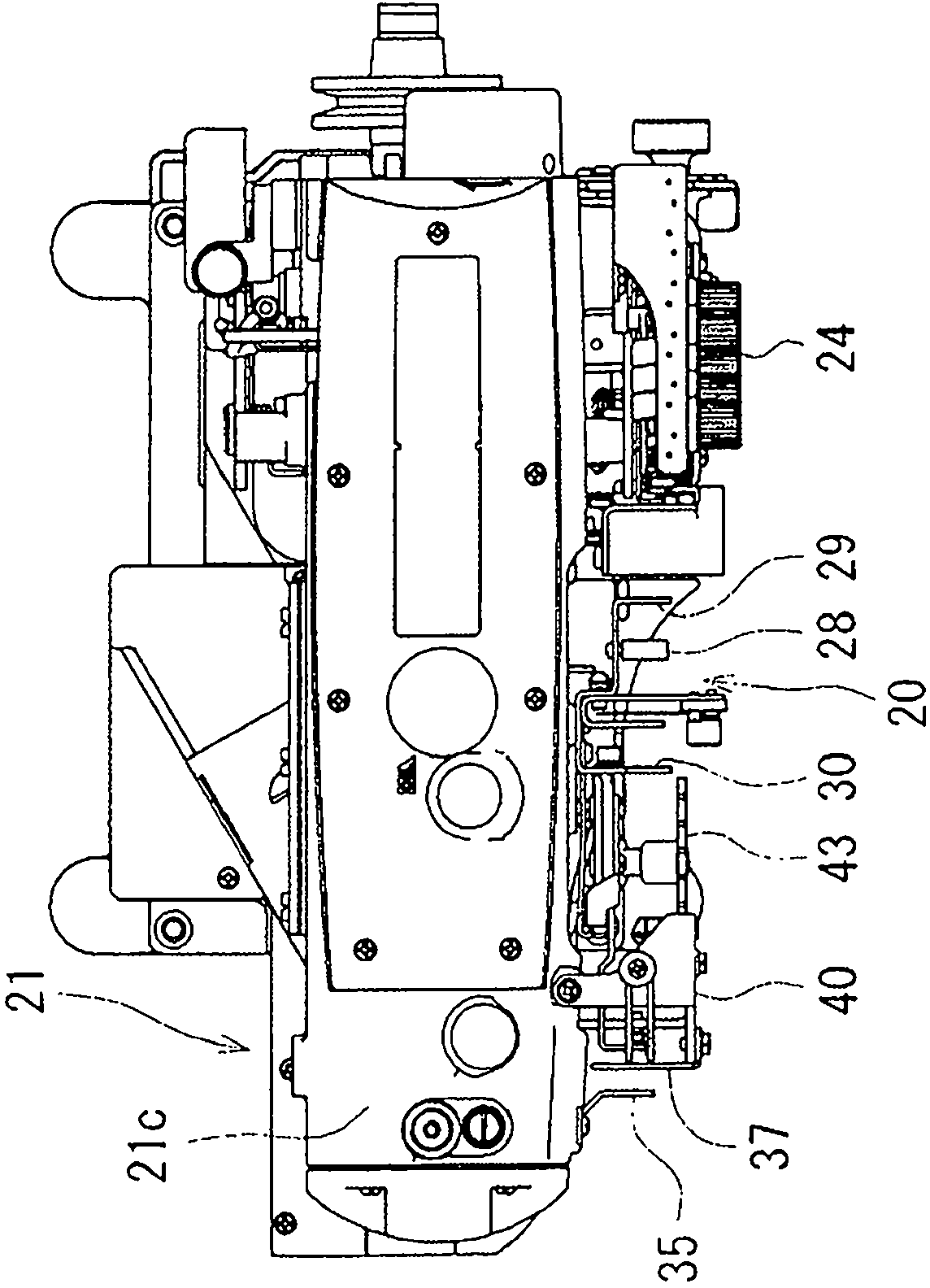

[0026] Figure 1~Figure 3 A sewing machine 21 as a double-thread lockstitch sewing machine having a thread feeding device 20 as an example of an embodiment of the present invention is shown. exist Figure 1~Figure 3 Among them, the sewing machine 21 has a base portion 21a, a vertical body portion 21b erected from the base portion 21a, and a sewing machine arm portion 21c extending from the vertical body portion 21b parallel to the base portion 21a.

[0027] Sewing machine 21 comprises: three thread grippers 24, and they are used for respectively applying prescribed tension to the suture passing through each needle 23 in the three needles 23 fixed on the lower end of needle bar 22, and needle bar 22 is formed by The main shaft of the sewing machine, not shown, is reciprocatingly driven up and down; the thread clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com