Thread ram means of sewing machine

A sewing machine and thread take-up technology, applied in the field of thread take-up devices, can solve the problems of complicated movement, changing the sewing style, and inability to obtain finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

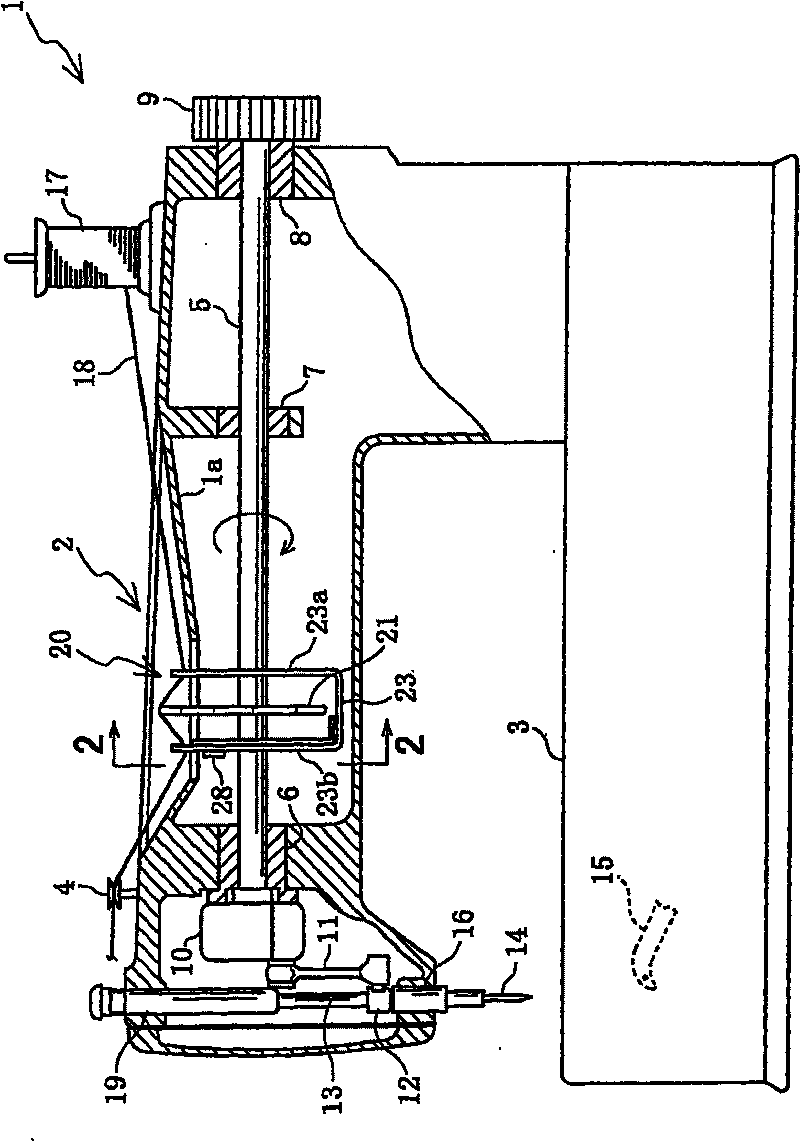

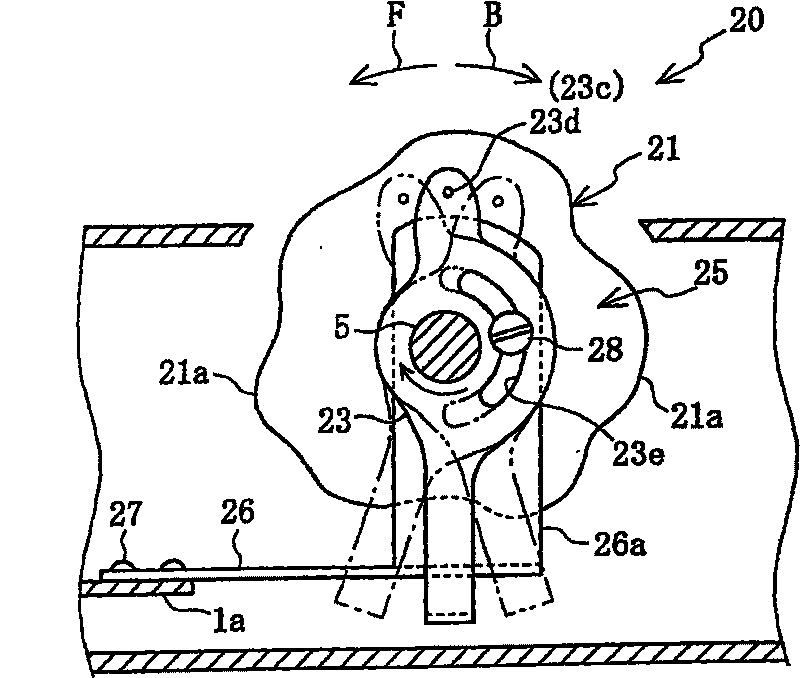

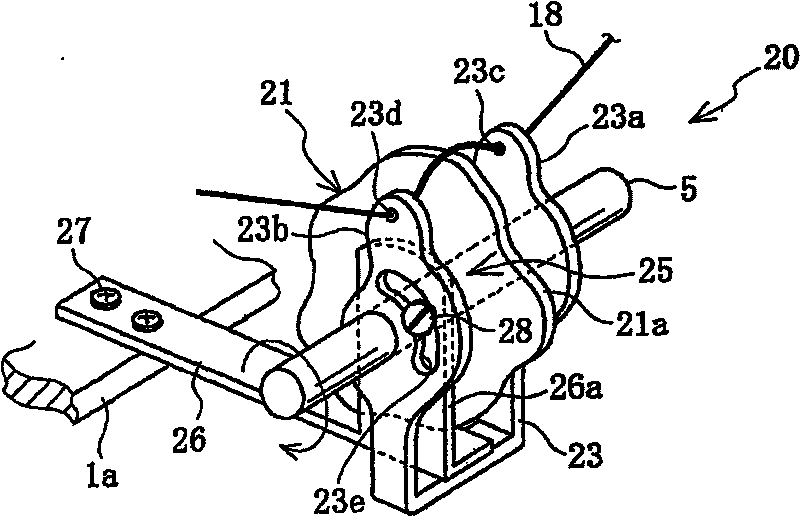

[0022] The thread take-up lever device of the sewing machine of this embodiment is provided with a concentric disc-type rotating thread take-up lever in the middle of the main shaft of the sewing machine provided on the arm of the double-chain stitch sewing machine with curved needles. The main shaft is equipped with guide plates of wire members on the left and right sides of the rotary thread take-up lever, and the wire members are rotatable centered on the main shaft of the sewing machine.

[0023] Refer below Figure 1 ~ Figure 5 The embodiment of the present invention is explained.

[0024] Such as figure 1 As shown, inside the arm 2 of the double chain stitch sewing machine 1, a sewing machine main shaft 5 (equivalent to a driving shaft integrally formed with the sewing machine main shaft 5) is arranged along its length direction (left and right direction), which is installed on the sewing mechanism frame 1a The upper bushings 6-8 are rotatably supported. A pulley 9 for manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com