Thread tension device of sewing machine

A technology of sewing machine and sewing machine head, applied in the direction of sewing machine thread take-up device, sewing machine metering device, sewing machine components, etc., can solve problems such as poor sewing, cloth feeding obstacle, bulge, etc., and achieve the effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

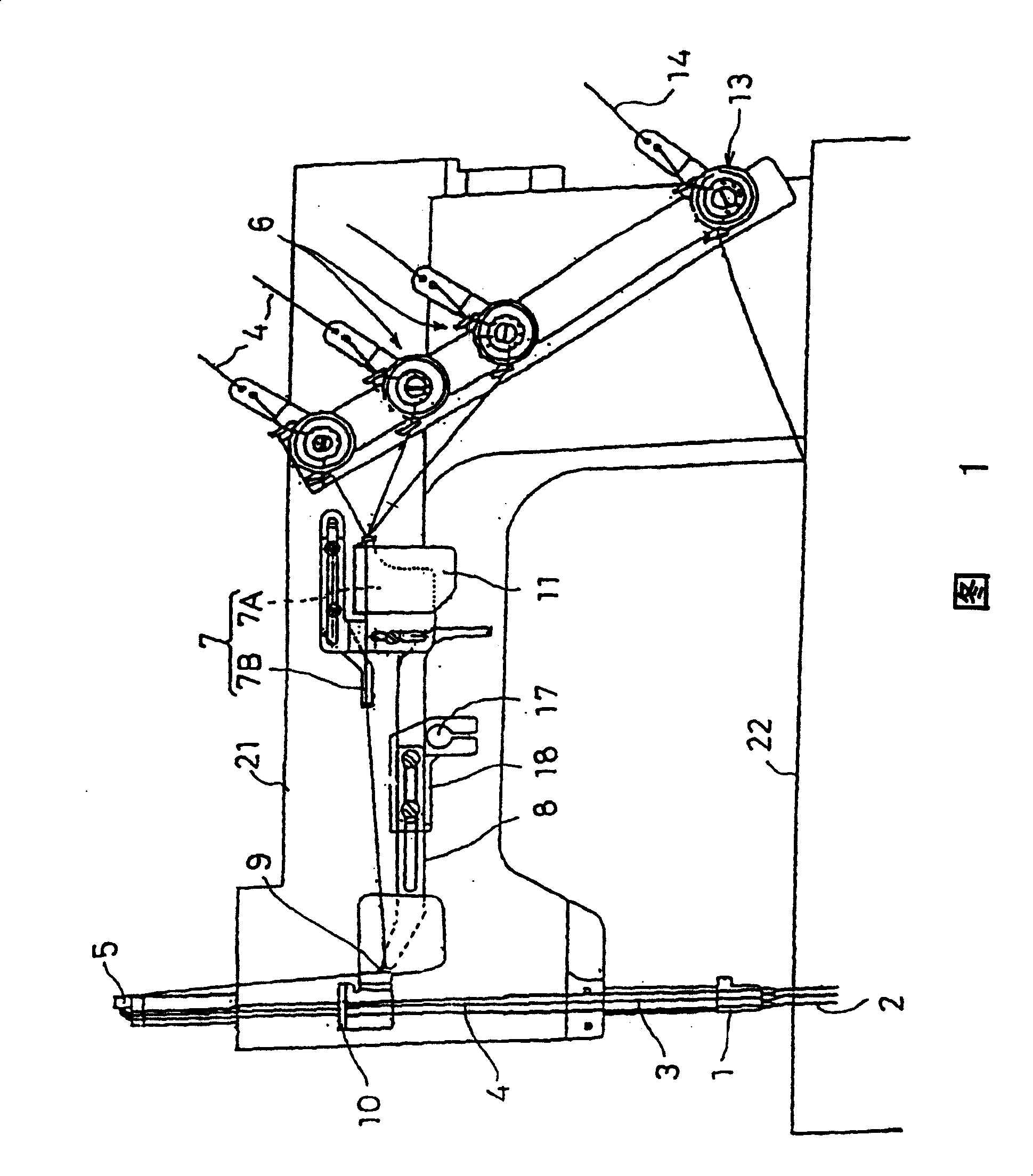

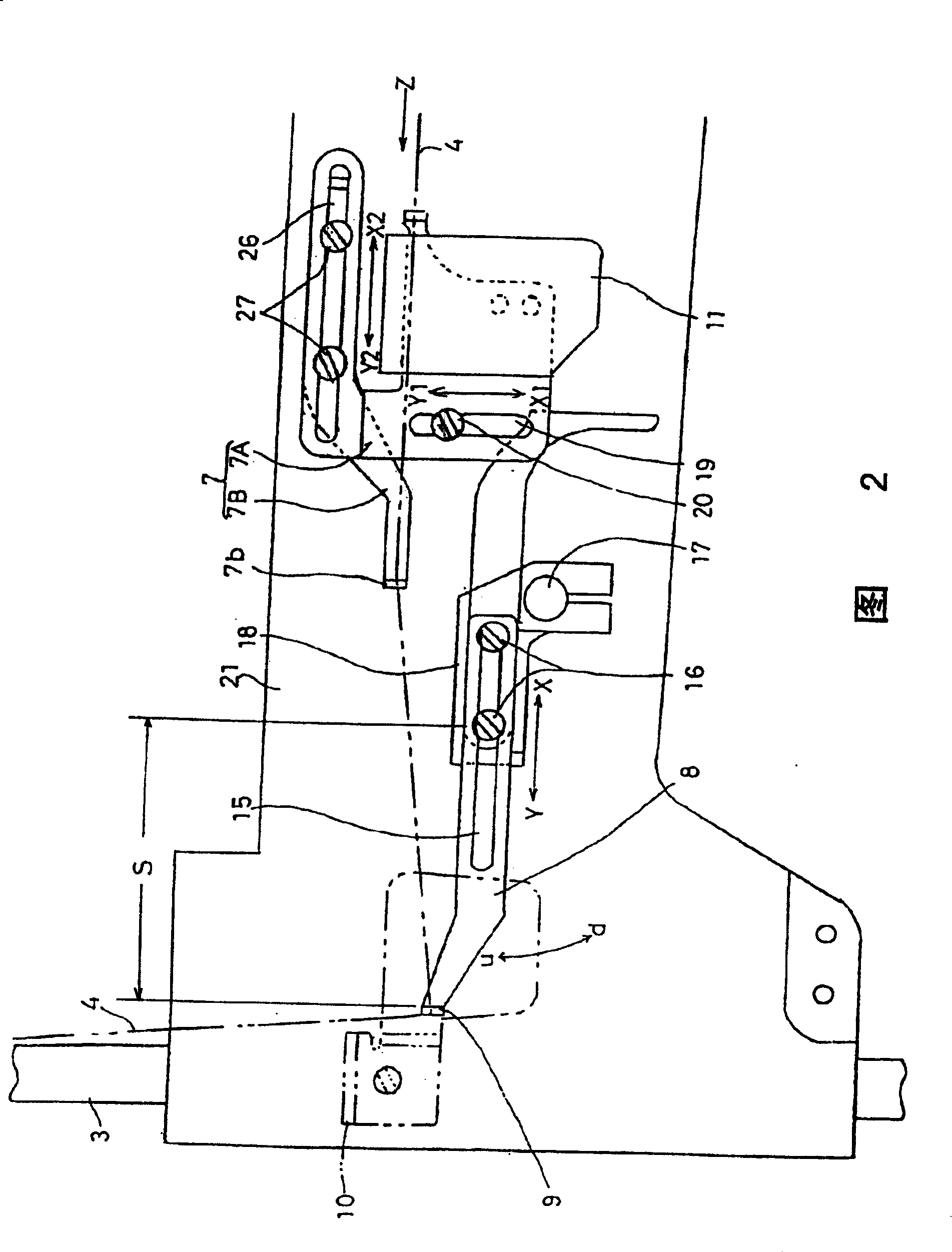

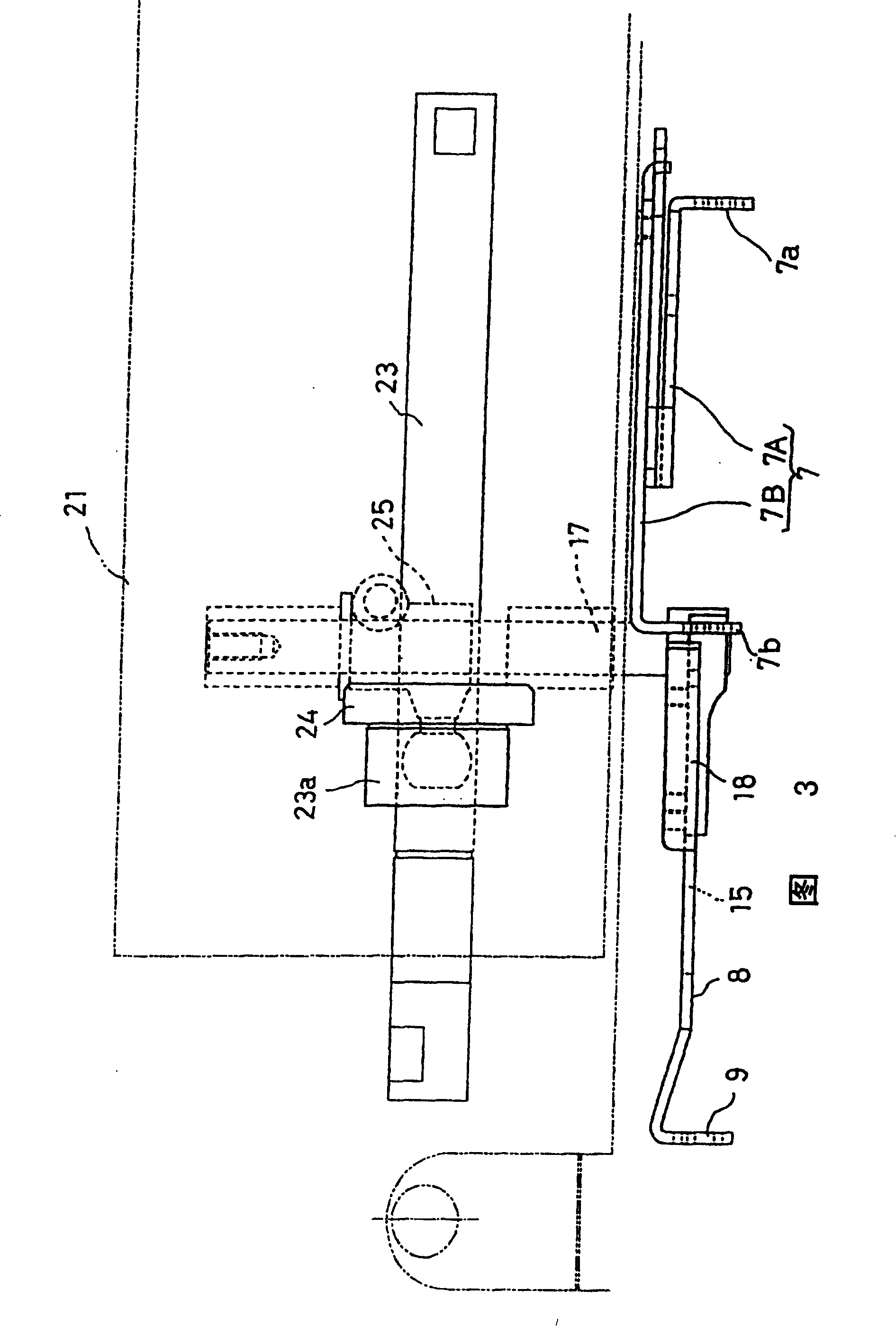

[0027] Embodiments of the present invention described in claims 1 to 6 will be described below with reference to the drawings.

[0028] In Fig. 1~Fig. 3, 21 is the sewing machine head shell, and 22 is the sewing machine base plate. In these Fig. 1~Fig. Figure 9 The same members that have been described in , therefore, the corresponding parts and the arrows indicating the moving direction of the movable member are respectively marked with the same symbols, and the detailed description thereof is omitted.

[0029] In the inside of the sewing machine head housing 21, the drive main shaft 23 that makes the needle bar 3 reciprocate up and down through a well-known crank mechanism or the like is inserted and supported. The bobbin arm 25 is passed to move interlockingly with the bobbin 17 which becomes the vertical swing fulcrum of the bobbin threading handle 8 .

[0030] Set on the front part of the left and right middle position of the sewing machine head housing 21, the fixed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com