Sewing machine

A sewing machine and upper thread technology, which is applied in the field of sewing machines, can solve problems such as broken upper thread J, unsmooth upper thread J, unstable resistance value, etc., and achieve the effect of reducing the possibility of thread breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

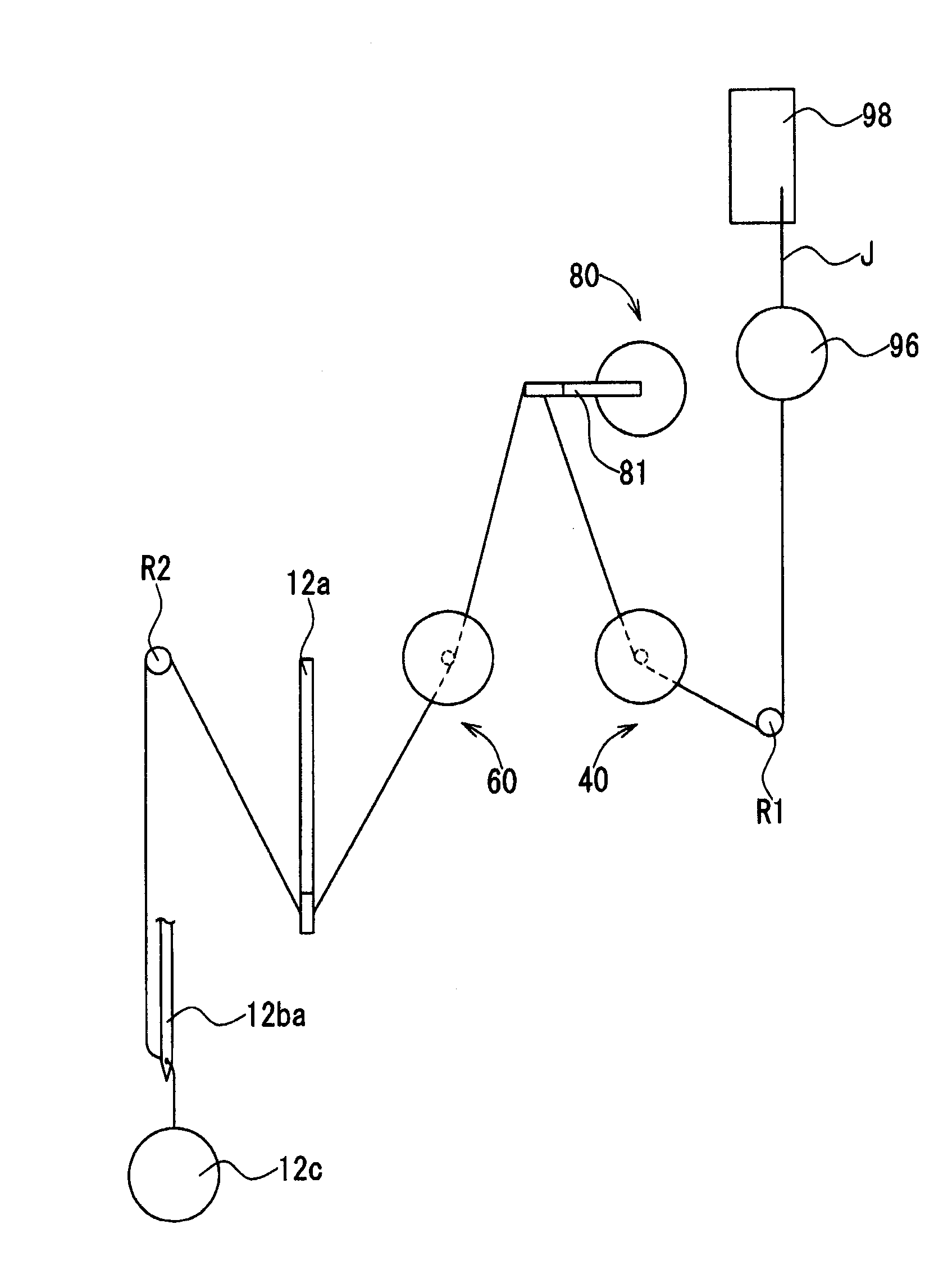

[0188] Based on the sewing machine 5 of Embodiment 1 of the present invention such as Figure 1 to Figure 5 As shown in the structure, it has: head 7, shuttle 12c, sewing frame (or holding frame, embroidery frame) 12d, frame driving device 24, and storage device 92. in addition, figure 2 is a drawing conceptually showing the main parts of the sewing machine 5, image 3 specifically expressed figure 2 Content.

[0189] Here, the machine head 7 is provided above a substantially flat sewing machine table (not shown). That is to say, frame 120 is erected from the upper surface of the sewing machine table (refer to image 3 , Figure 4 ), the machine head 7 is provided on the front side (Y1 side) of the frame 120 .

[0190] Head 7 such as figure 1 , image 3 , Figure 4 As shown in the structure, it has: mechanical element group 10, spindle motor 20, spindle 22, upper thread control part 30, control circuit 90, pretensioner 96, winding thread 98 wound on the upper threa...

Embodiment 2

[0295] Next, the sewing machine of the second embodiment will be described. The sewing machine 205 based on Embodiment 2 is an embroidery sewing machine, such as Figure 25 ~ Figure 28 As shown in the structure, it has: a head (embroidery head) 207, a shuttle 12c, a sewing frame 12d, a frame driving device 24, and a storage device 92. The sewing machine 205 is a multi-needle sewing machine, specifically, a six-needle embroidery sewing machine capable of handling six types of upper threads.

[0296] Here, the machine head 207 is provided above a substantially flat sewing machine table (not shown) similarly to the machine head 7 . That is, a frame 320 is erected from the upper surface of the sewing machine table (refer to Figure 27 ), a machine head 207 is provided on the front side of the frame 320 .

[0297] Head 207 as Figure 25 ~ Figure 28 The structure shown in the figure includes: a mechanical element group 10 , a spindle motor 20 , a spindle 22 , a needle thread con...

Embodiment 3

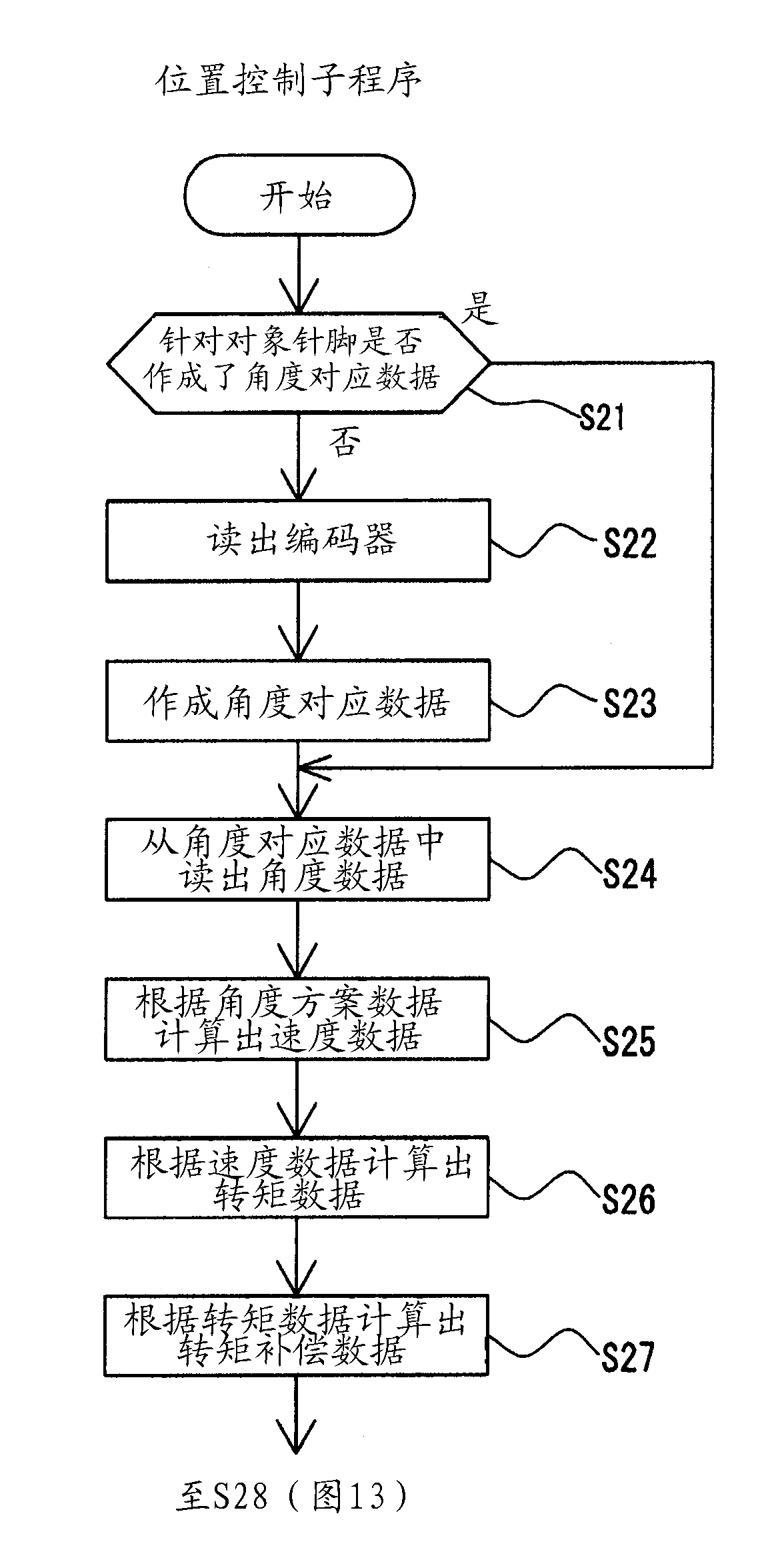

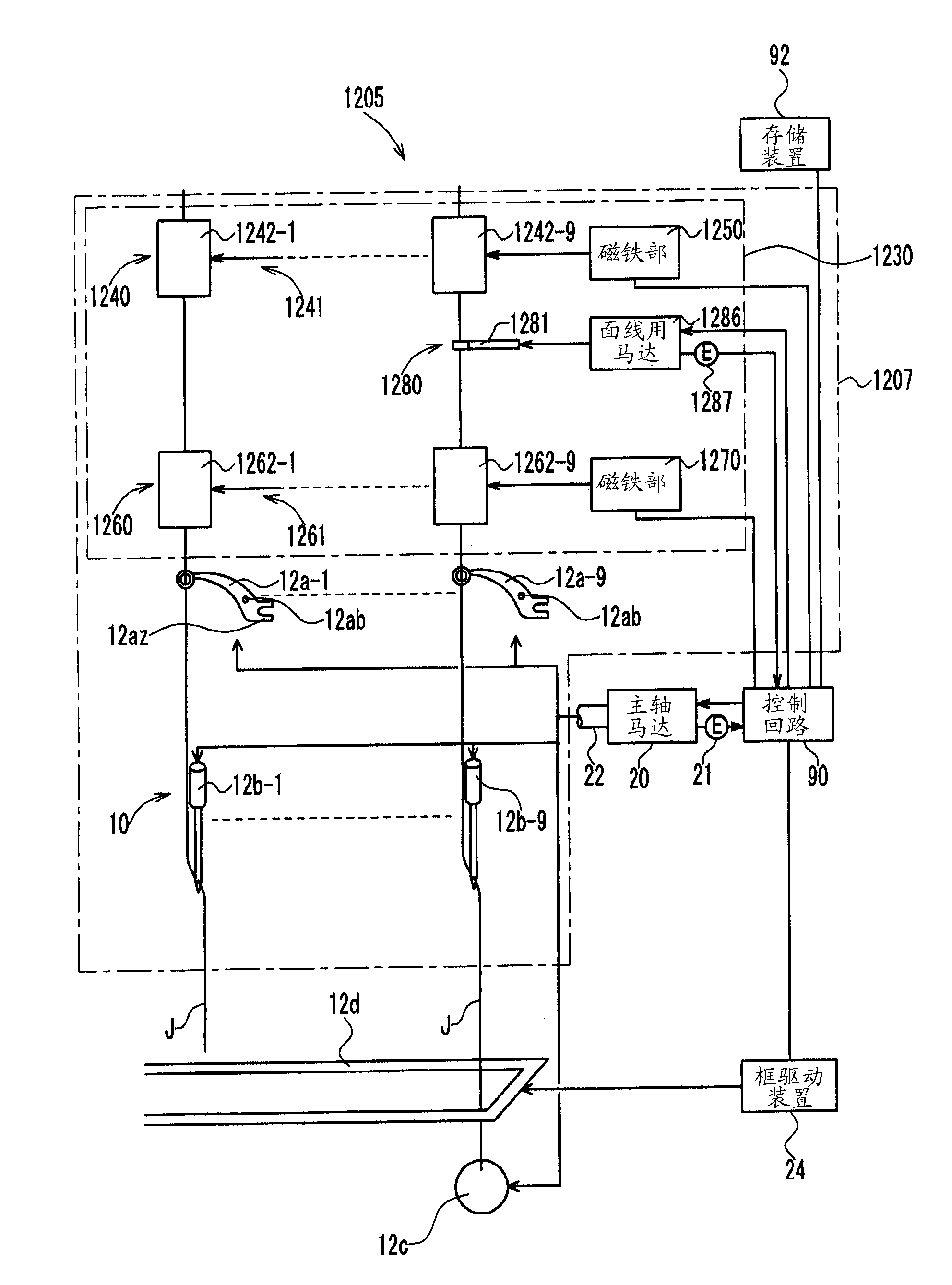

[0366] Next, the sewing machine of the third embodiment will be described. The sewing machine 1205 based on Embodiment 3 is an embroidery sewing machine, such as Figure 29 ~ Figure 36 As shown in the structure, it has: head (embroidery head) 1207, shuttle 12c, sewing frame 12d, spindle motor 20, spindle 22, frame drive device 24, control circuit 90, and storage device 92. This sewing machine 1205 is a multi-needle sewing machine, specifically, a 9-needle embroidery sewing machine that can handle nine types of upper threads.

[0367] in addition, Figure 33 , Figure 34 Only the needle thread control mounting part 1340 and the needle thread control part 1230 are placed on the Figure 32 The left side view of the partial cross-section cut at the P-P position in the middle, Figure 35 Only the needle thread control mounting part 1340 and the needle thread control part 1230 are placed on the Figure 32 Partial cross-sectional left side view cut at Q-Q position in middle. an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com