Thread return device of sewing machine

A sewing machine and thread device technology, which is applied to sewing machine measuring devices, sewing machine components, and thread cutting mechanisms in sewing machines, etc., can solve the problems of complicated recovery time for sewing operations, cutting sewing threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] (Chain Stitch Sewing Machine)

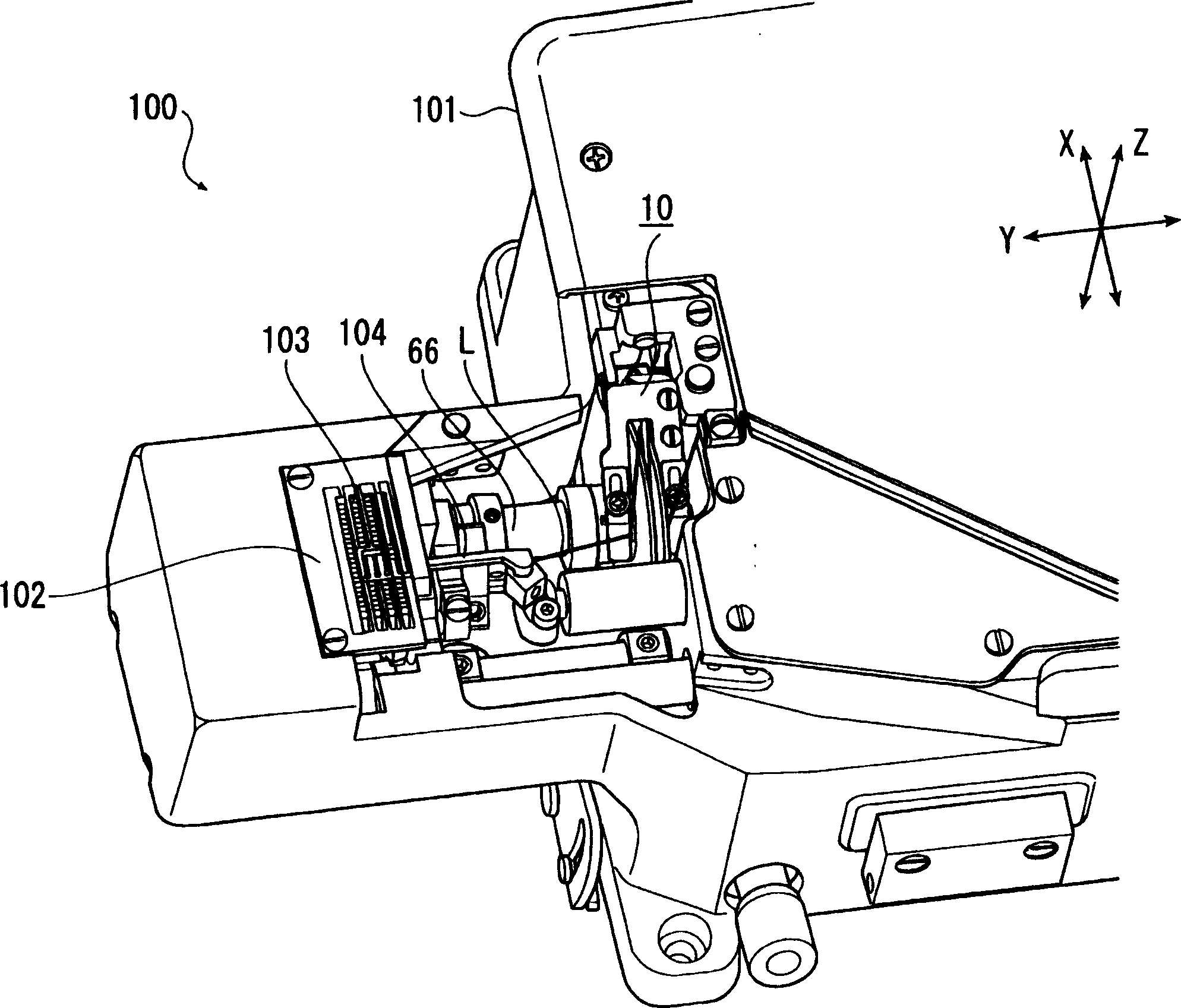

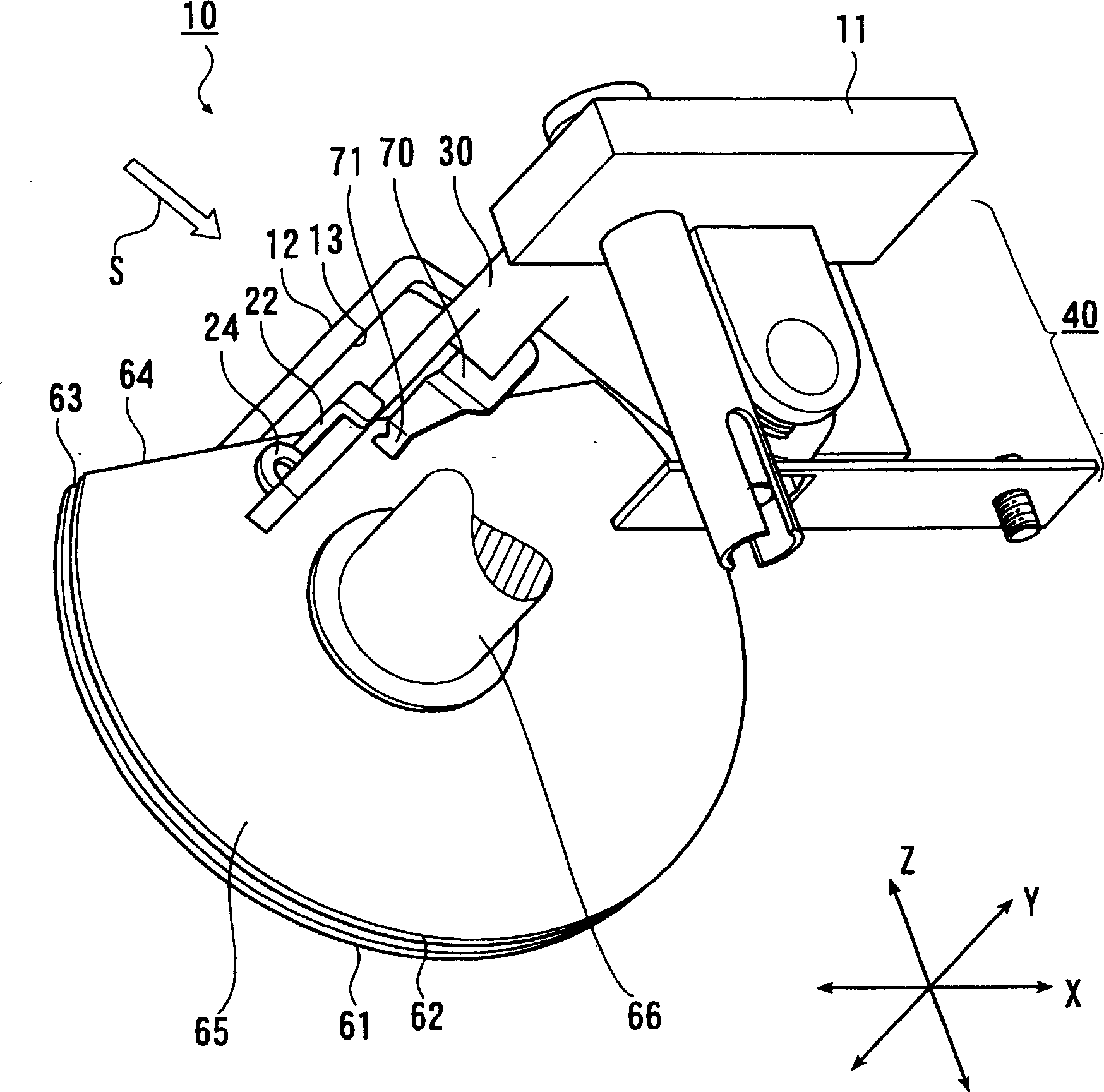

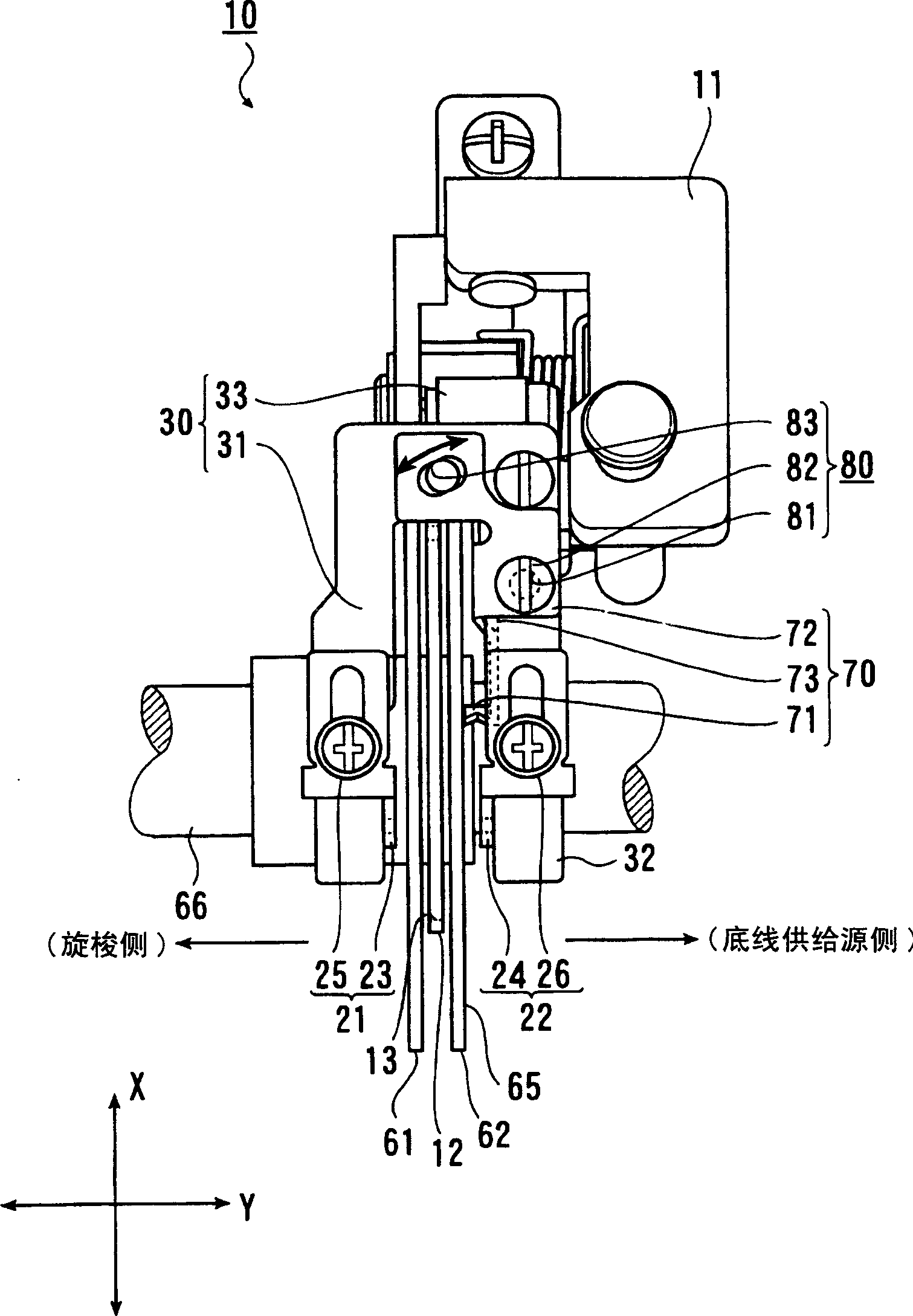

[0041] refer to Figure 1 to Figure 14 , the bobbin thread adjusting device 10 as the thread rewinding device according to the embodiment of the present invention will be described. figure 1 It is a perspective view of a state in which the bobbin thread unwinding device 10 is assembled on the sewing machine 100, figure 2 It is a perspective view of the bobbin thread unwinding device 10 viewed obliquely from below, image 3 yes figure 2 The view in the direction of the arrow S.

[0042] First, the double chain lockstitch sewing machine 100 provided with the bobbin thread unwinding device 10 will be described. Such asfigure 1 and Figure 6 As shown, the sewing machine 100 has a box-shaped bottom plate portion 101, a vertical body portion (not shown) is erected from the right end portion of the bottom plate portion 101, and extends approximately parallel to the bottom plate portion from the upper portion of the vertical body portion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com